- Joined

- Jan 3, 2015

- Messages

- 400

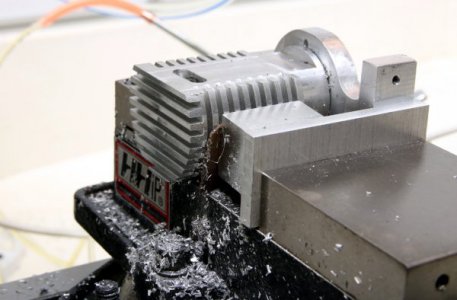

Is the general term for that a castle nut wrench?

That's what I thought, but I was told it isn't a wrench. It is more like a jig or a fixture to hold the whole assembly together to get it into and out of the car. I think the teeth are just for aligning everything. I really couldn't say for sure though...Is the general term for that a castle nut wrench?

That's what I thought, but I was told it isn't a wrench. It is more like a jig or a fixture to hold the whole assembly together to get it into and out of the car. I think the teeth are just for aligning everything. I really couldn't say for sure though...

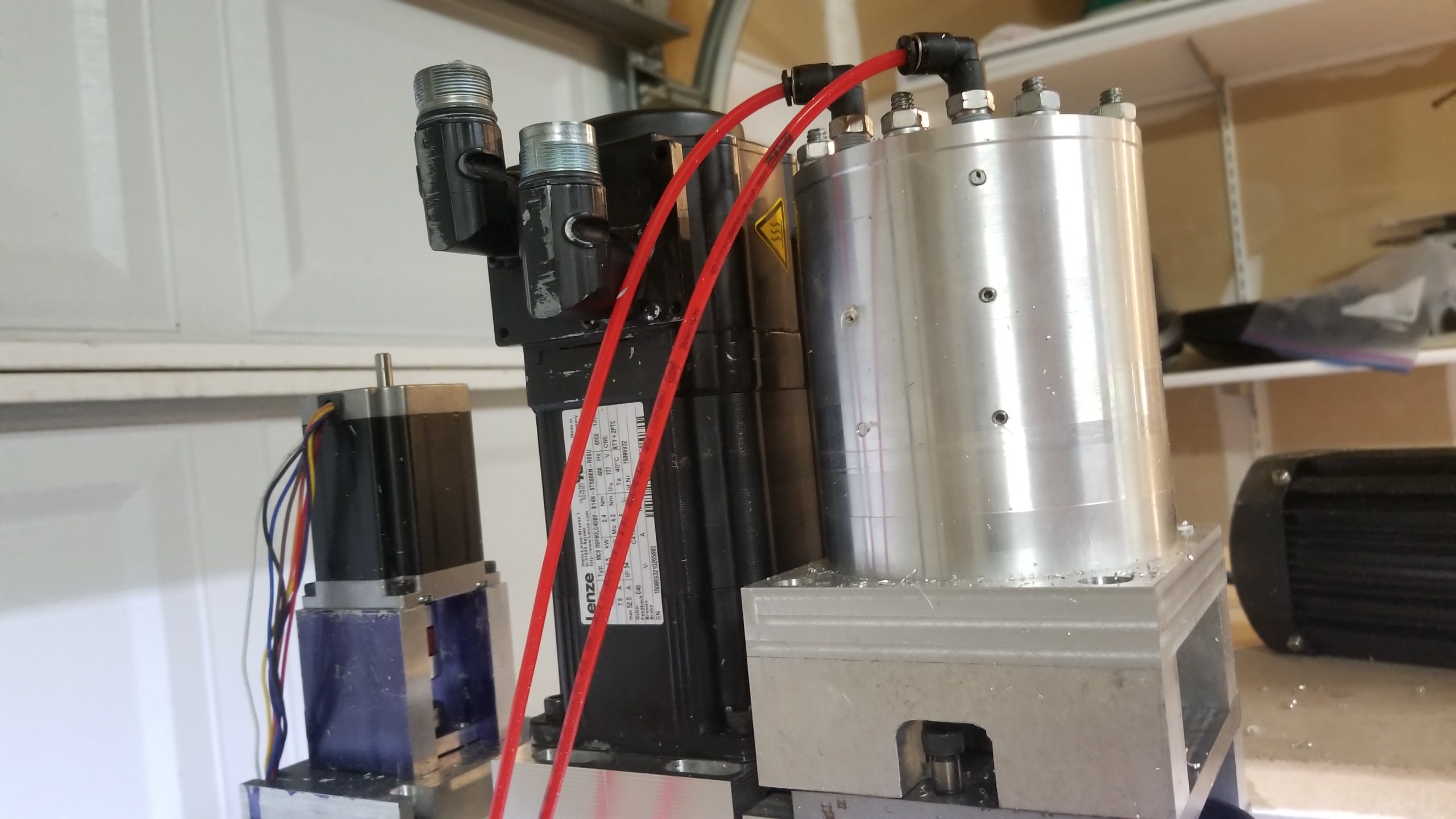

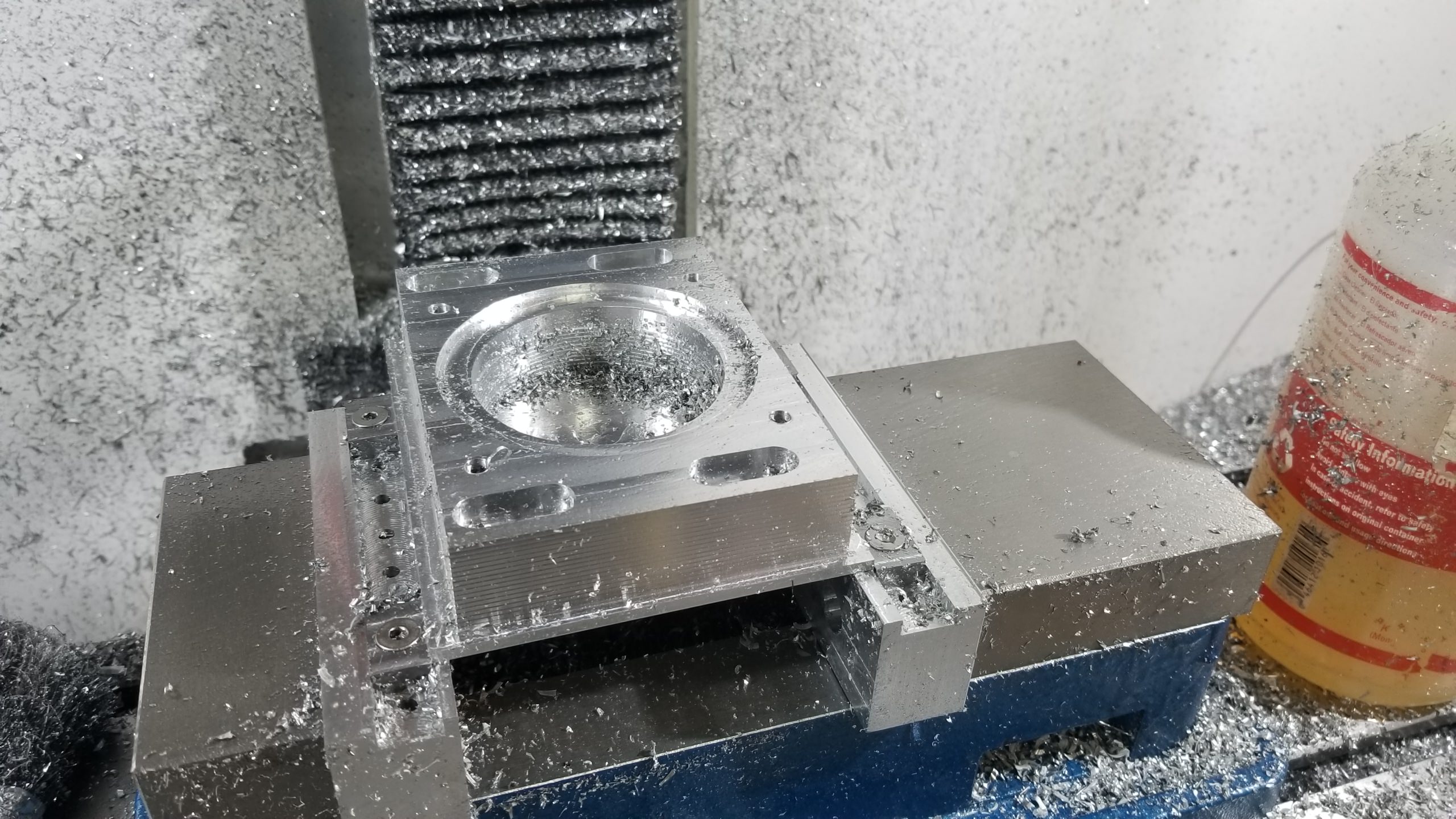

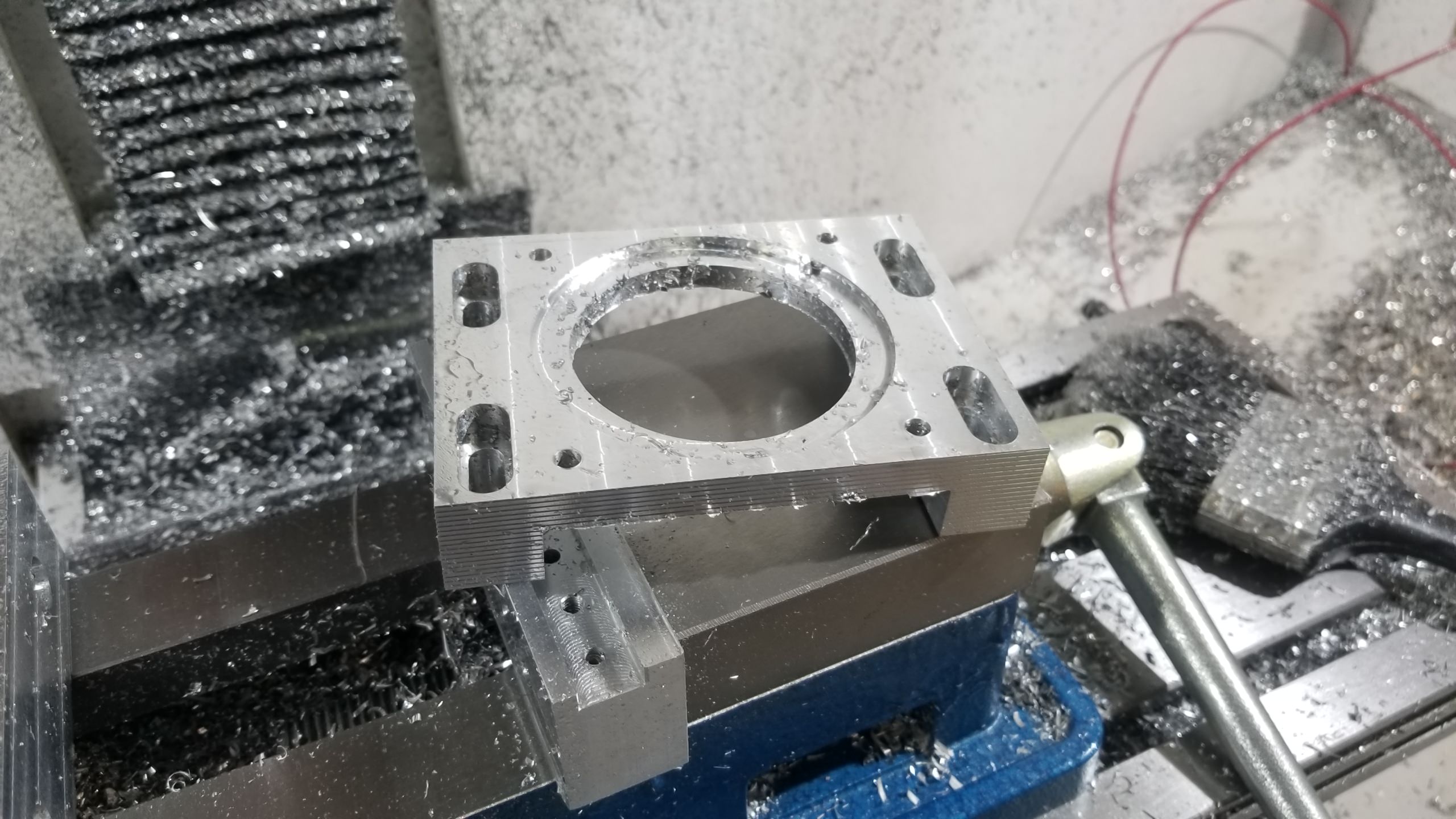

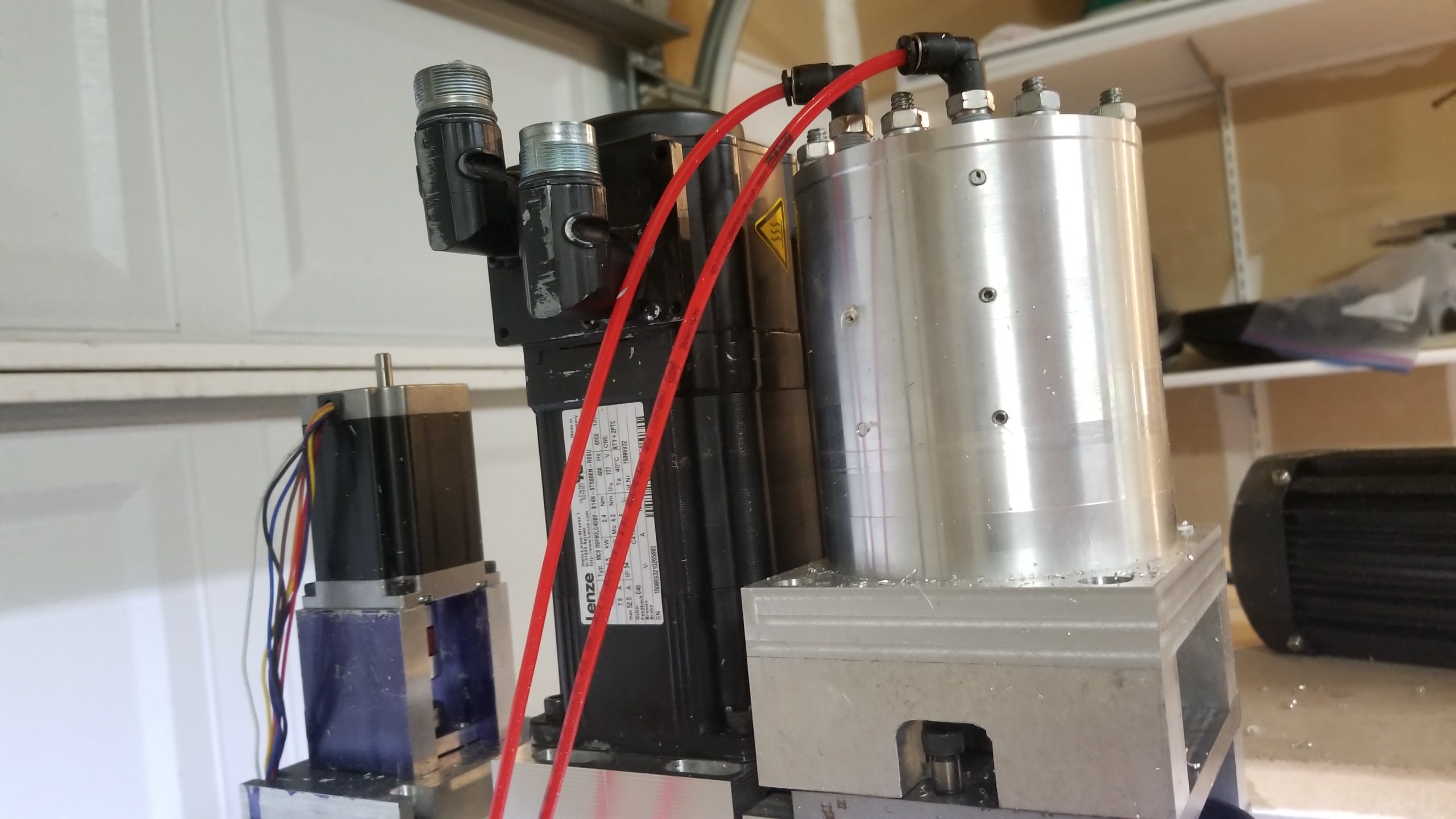

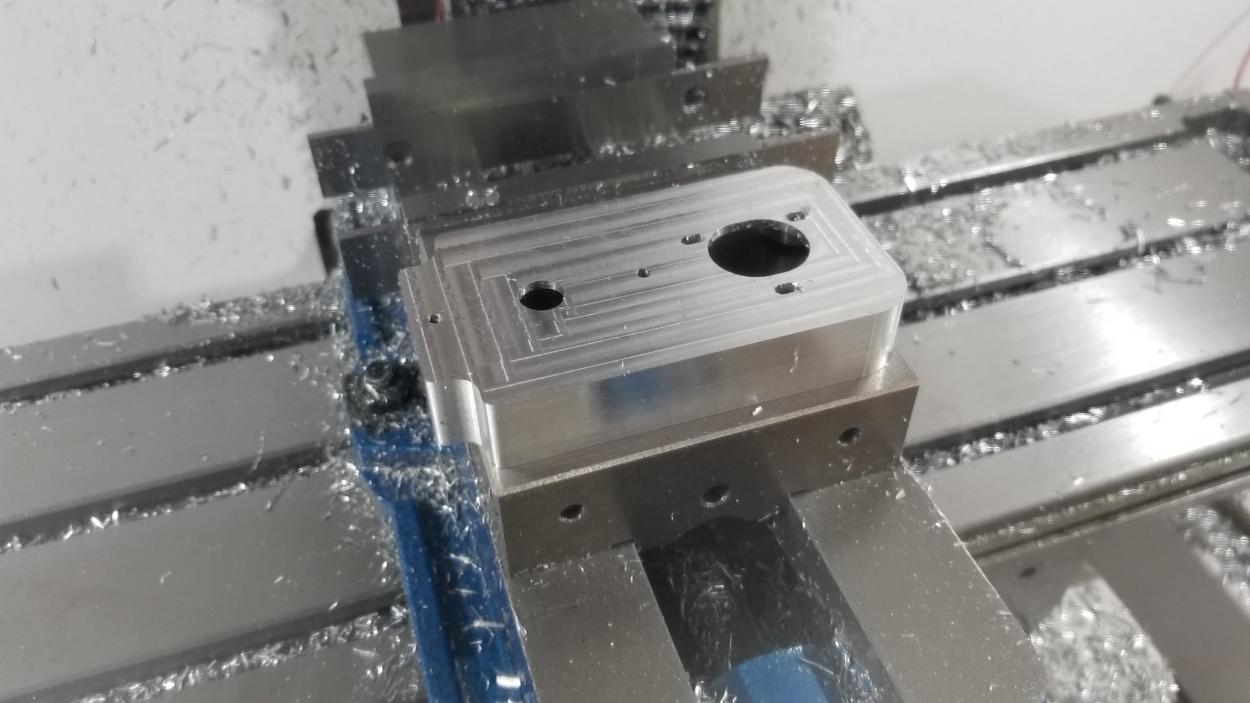

Not to hijack this picture thread, but I'm in the planning stages of switching to an AC servo for a spindle motor. Currently have a 2ph induction that is too big to fit a standard air cylinder on the head. PM please if you have a few minutes to discuss.I made a motor mount for a 2 HP servo motor for my spindle, a Nema 34 stepper mount, a set of mitee bites talon soft jaws and clamps and stepper encoder mounts.