- Joined

- Jan 3, 2015

- Messages

- 400

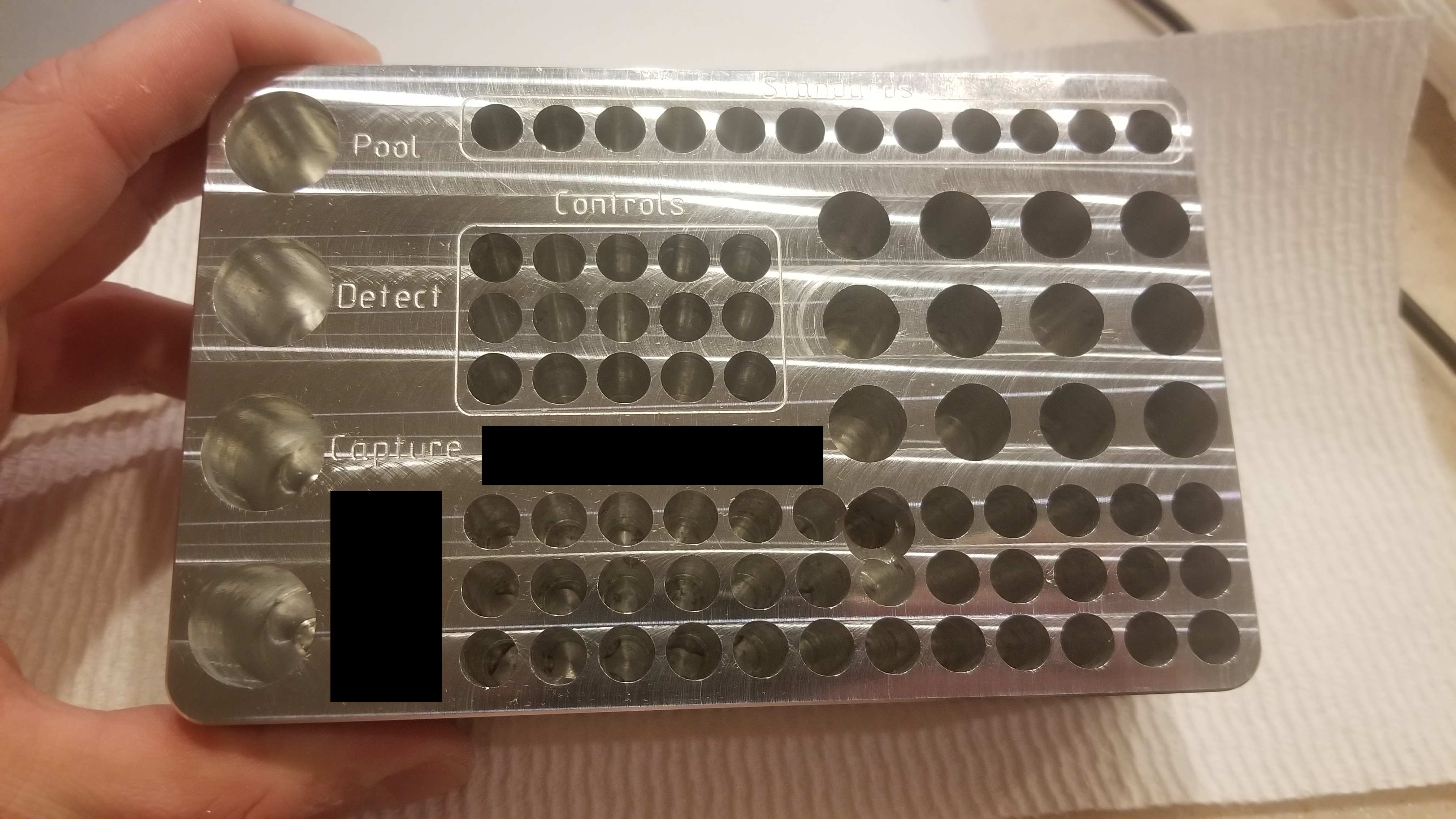

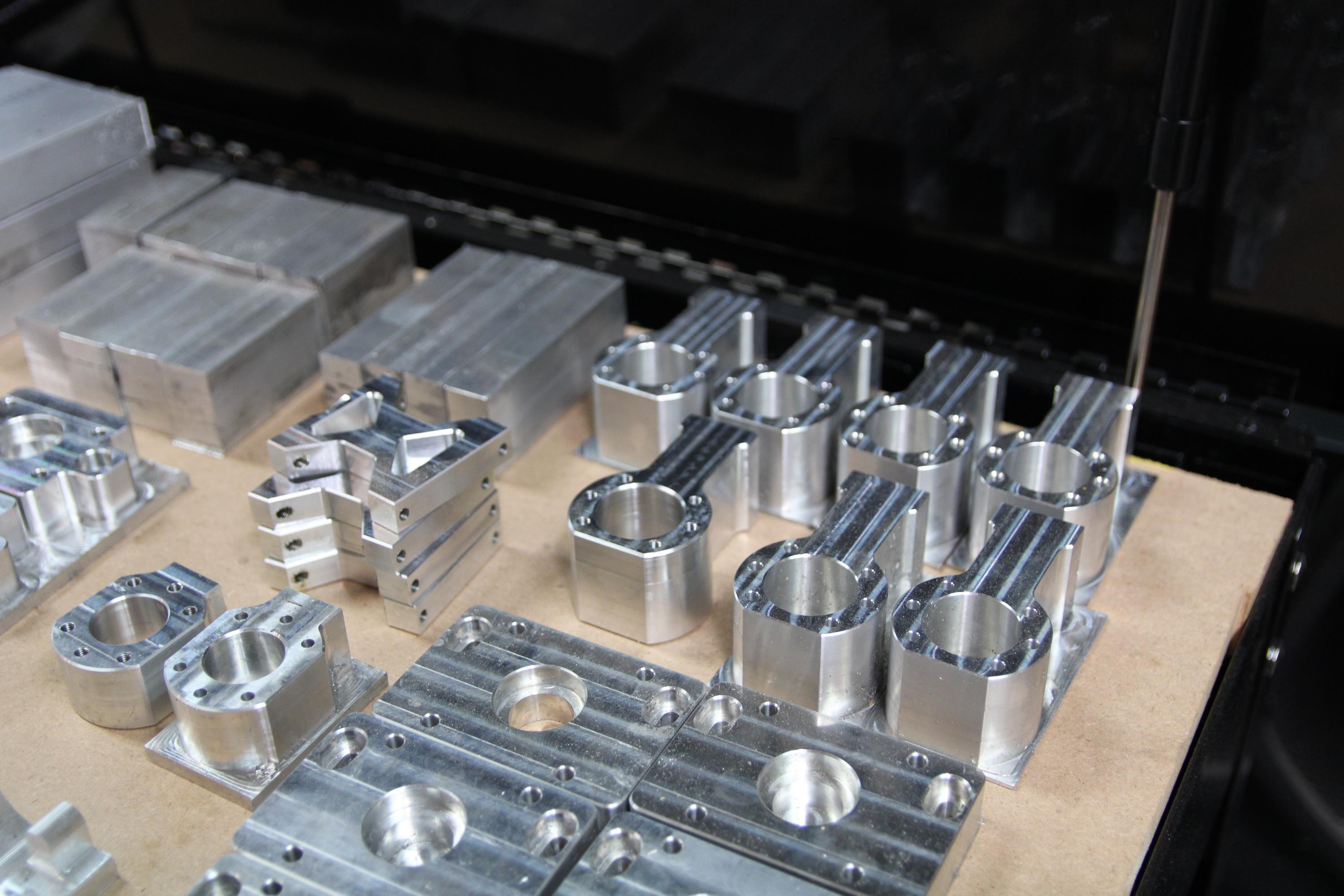

Sweet! 10 places?

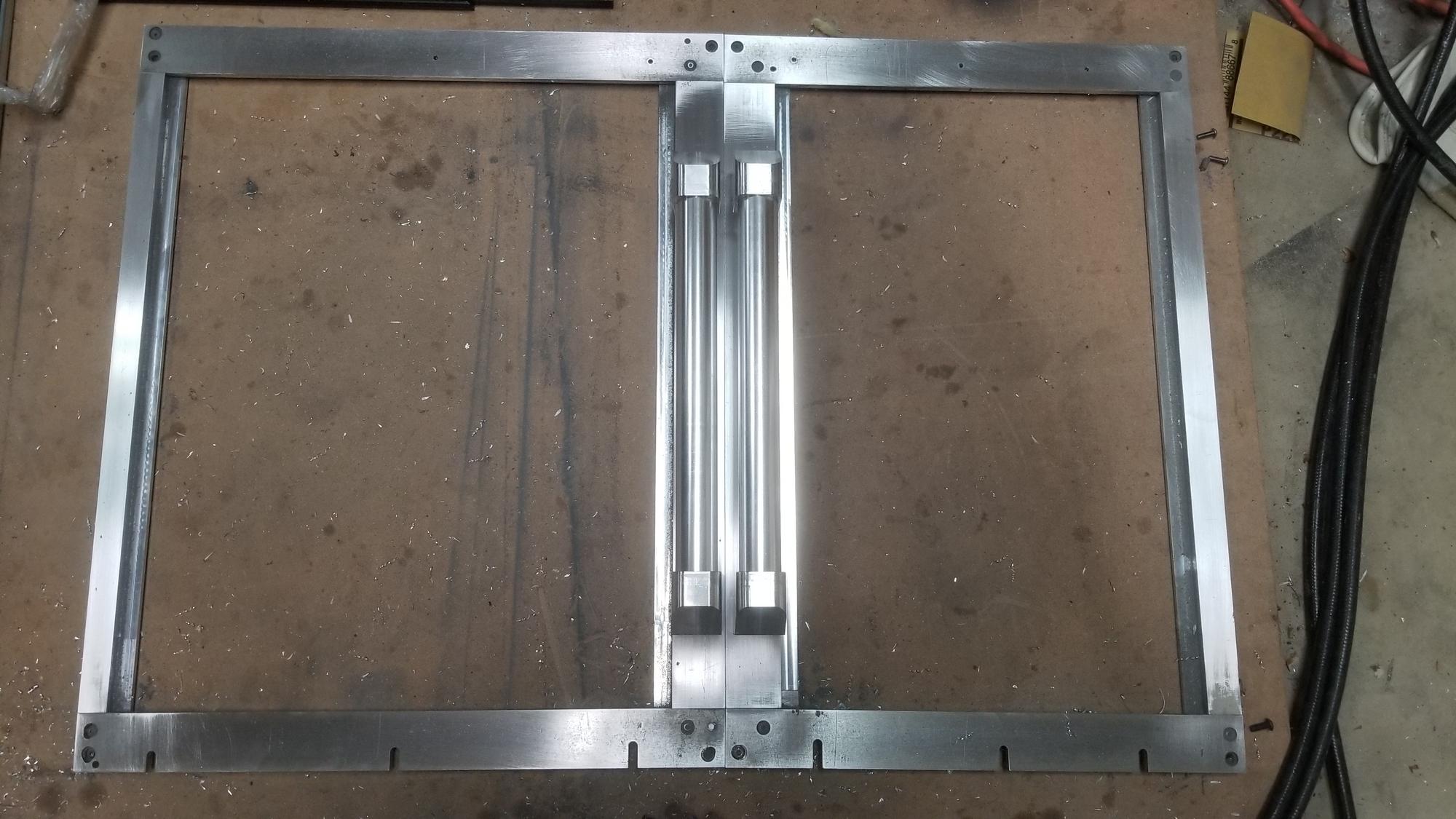

You ought to consider making a video of it in action. A couple of changes is plenty. It looks like instead of being at the end of the table and permanently located there, it's attached to the mill's headstock. That would mean instead of slewing the table over to grab the tool, the tool changer slews over to the spindle for the change. Probably faster.

Interesting!

You ought to consider making a video of it in action. A couple of changes is plenty. It looks like instead of being at the end of the table and permanently located there, it's attached to the mill's headstock. That would mean instead of slewing the table over to grab the tool, the tool changer slews over to the spindle for the change. Probably faster.

Interesting!