- Joined

- Dec 3, 2013

- Messages

- 1,844

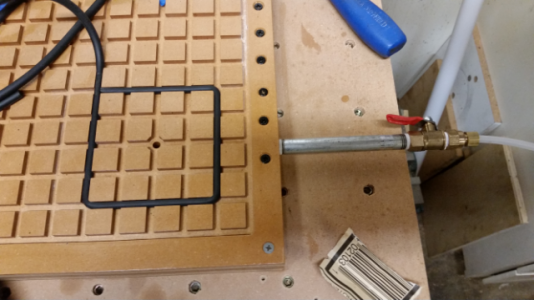

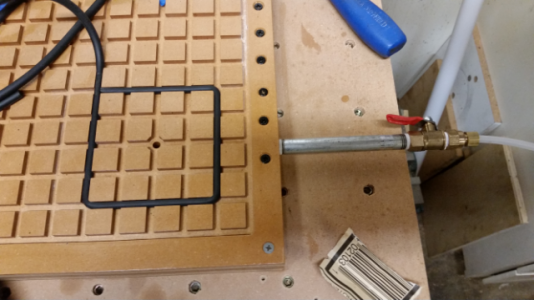

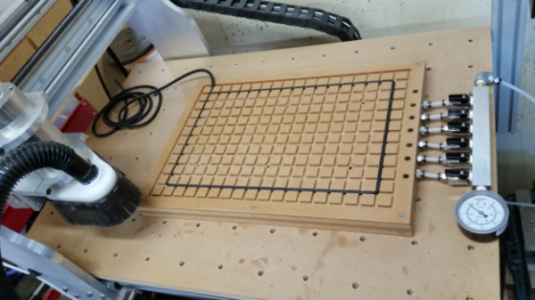

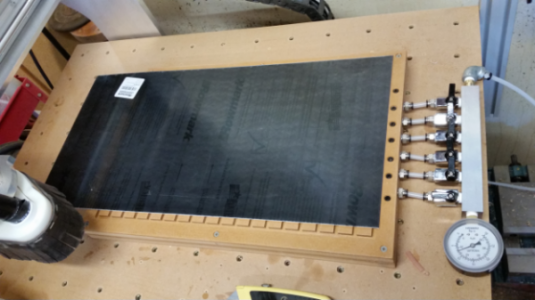

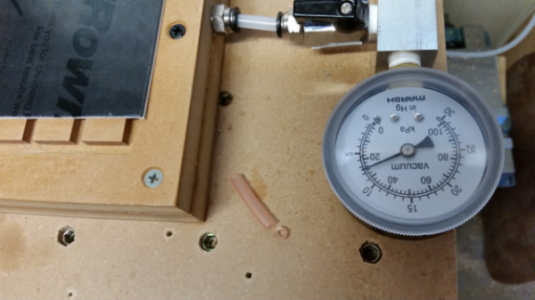

I changed the oil in my vacuum pump and it is now pulling 27 inches so that's good. The silicone tubing does not seem to be working so I got some 1/4" soft burna rubber cord. I re-cut the grid to 0.240" wide. The rubber cord is a little tight but not bad. With one port hooked up I can pull a vacuum on 1/16" and 1/8" metal but the 1/16" engraving plastic is is not stiff enough to get a seal. I'm still not sure if the volume is too low with the pump only being 1.5 cfm. I see other systems using 5 and 6 cfm pumps. I'm still waiting for some fittings to do the manifold.