- Joined

- Feb 27, 2015

- Messages

- 105

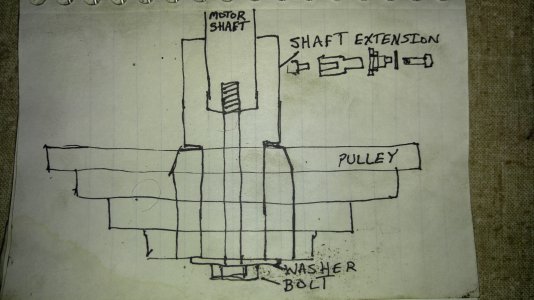

I am thinking of fastening the pulley to the motor in this way. The bolt will be grade 8 and loctited in place. The shaft extension is near press fit on both the pulley and motor shaft. The extension was fit to the motor shaft first. Then I chucked the motor into the lathe and turned the extension to fit the pulley to eliminate as much wobble or runout as I could. I think maybe a pin on the side of the shaft or threaded pin through the motor shaft and extension and another through the extension and pulley after it is assembled. Or is that necessary?

I am thinking of fastening the pulley to the motor in this way. The bolt will be grade 8 and loctited in place. The shaft extension is near press fit on both the pulley and motor shaft. The extension was fit to the motor shaft first. Then I chucked the motor into the lathe and turned the extension to fit the pulley to eliminate as much wobble or runout as I could. I think maybe a pin on the side of the shaft or threaded pin through the motor shaft and extension and another through the extension and pulley after it is assembled. Or is that necessary?