- Joined

- Mar 26, 2018

- Messages

- 8,407

Many of you would agree, in a small shop we need to use our space as efficiently as possible.

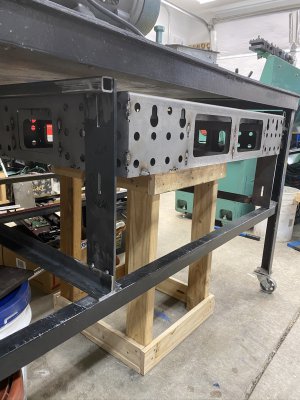

The plan is to mount the plasma table under the welding/work table so I can pull it out when needed and close the drawer when not in use.

I need your advice. I may need another hand or two.

Have you ever been in the thick of it and you needed another hand or two? Of course you have.

The pics show my most immediate cunundrum.

I assembled the plasma table this morning. Certifflat products are great. It took about half an hour to complete the kit.

I need to support the table in it’s proper position while I mark the drawer slides for drilling.

My plan as I write this, is to build a shelf out of wood that holds the table in the correct position. In other words, the table will be sitting in it’s final position All I need to do is slide the frames over and mark the supports accordingly for welding and drilling.

What would you do at this point?

Thank you!

The plan is to mount the plasma table under the welding/work table so I can pull it out when needed and close the drawer when not in use.

I need your advice. I may need another hand or two.

Have you ever been in the thick of it and you needed another hand or two? Of course you have.

The pics show my most immediate cunundrum.

I assembled the plasma table this morning. Certifflat products are great. It took about half an hour to complete the kit.

I need to support the table in it’s proper position while I mark the drawer slides for drilling.

My plan as I write this, is to build a shelf out of wood that holds the table in the correct position. In other words, the table will be sitting in it’s final position All I need to do is slide the frames over and mark the supports accordingly for welding and drilling.

What would you do at this point?

Thank you!