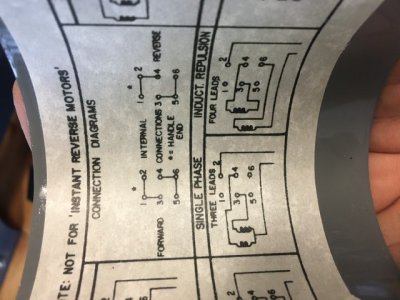

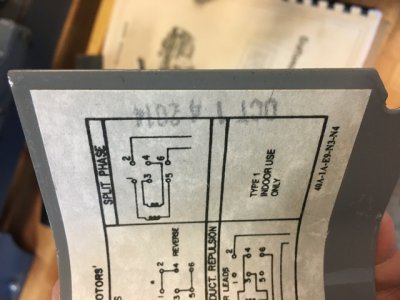

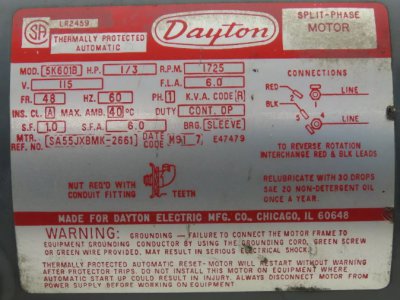

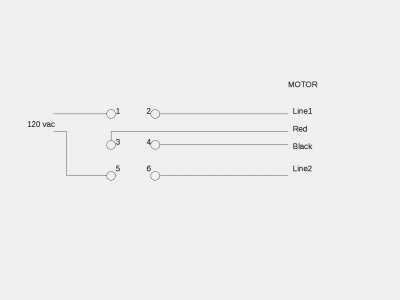

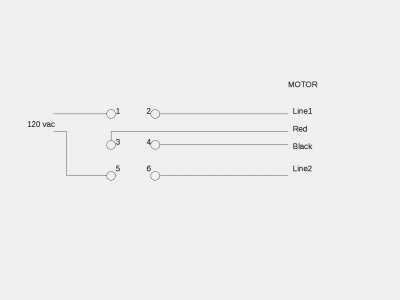

Hello all new to this form and thank you in advance for any assistance I may receive. I recently acquired a craftsman 101/atlas 618 lathe and fully tore it down and built it back up. I did pick up a Dayton 1/3 hp 110 motor for it and the last thing I have to do is wire the motor to the drum switch. Is there anyone that can tell me the correct way to wire this so I don’t smoke the motor? I will attach the wiring diagram on the motor and in the drum switch. Please bear in mind I’m no electrician. Any help is super appreciated. Can’t wait to start making some chips!!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please help with wiring drum switch!

- Thread starter Sharmack

- Start date

- Joined

- Sep 1, 2018

- Messages

- 637

The guru’s will be along shortly. They know their stuff. Welcome.

- Joined

- Sep 1, 2018

- Messages

- 637

Hit post to quick. Welcome to the site. Lots of sharp people on here.

- Joined

- Mar 16, 2020

- Messages

- 157

Does the left side of the diagram that isnt shown show the internal connections made? That might help seeing.

- Joined

- Apr 30, 2015

- Messages

- 11,259

Hi Sharmack, I'll do a sketch for you in a few- I want to point out that style of motor has somewhat low starting torque. May not be an issue for a small lathe like a 618.

-Mark

This should work. Extend the red and black wires as long as needed to reach the drum switch. Swap them if necessary to reverse the rotation.

Be sure to provide a good ground for your machine, directly to the motor case, drum switch case, and the lathe itself. Safety first!

-Mark

This should work. Extend the red and black wires as long as needed to reach the drum switch. Swap them if necessary to reverse the rotation.

Be sure to provide a good ground for your machine, directly to the motor case, drum switch case, and the lathe itself. Safety first!

Last edited:

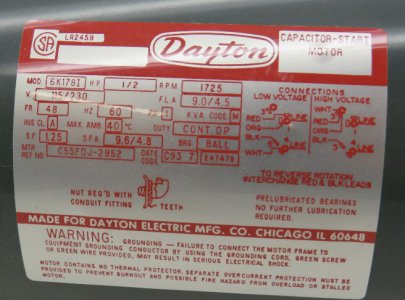

Wow thanks for the responses. I was worried about the torque as well. I ended up with this just because I wasn’t sure what to get to be honest. This seemed to closely match the Specs of the motor that wasn’t working that came with it. In the event the starting torque is an issue and I do have to get another motor is there a certain style you would suggest? I attached a pic of the lathe as well just so you guys can see what I’m working on. Thank you again!

Attachments

- Joined

- Apr 30, 2015

- Messages

- 11,259

Pretty much the same thing only capacitor start, the ones with the "bump" on the side

I think your split-phase motor will do the job though, as long as your countershaft drive turns smoothly with low friction. If there is going to be an issue, it will show up when the belts are set for the highest spindle speeds

-M

I think your split-phase motor will do the job though, as long as your countershaft drive turns smoothly with low friction. If there is going to be an issue, it will show up when the belts are set for the highest spindle speeds

-M

Last edited: