hi I am new and I bought a1127 lathe with the DRO I am very unhappy with the DRO when I move the X is ok but if I shake the top of the lathe it change the reading. I secure the DRo bar and is ok now. but if I cero it the DRO and the lathe, if I make a complet turn on the lathe the DRO should give me 2 cero, cero,cero etc. but it do not it give me 17 something , or 16 something and so forth. what is going on. who should I trust, the lathe or the DRO.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-1127 DRO Questions

- Thread starter nescosmo

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,852

hi I am new and I bought a1127 lathe with the DRO I am very unhappy with the DRO when I move the X is ok but if I shake the top of the lathe it change the reading. I secure the DRo bar and is ok now. but if I cero it the DRO and the lathe, if I make a complet turn on the lathe the DRO should give me 2 cero, cero,cero etc. but it do not it give me 17 something , or 16 something and so forth. what is going on. who should I trust, the lathe or the DRO.

Welcome!

Use a trustworthy indicator to measure travel. That will tell you if it's the DRO or the lathe's dials that are off. Some import lathes use metric leadscrews so the conversion can be off.

I do not know were to go to express my thoughts on this forums, I am new. I check the lathe today I secure all the bolt and so forth, and on my DRO X went on the lathe from 0 to 0 and check the reading and the sus traction was 700 or 900 sometimes 1000 and sometimes 985, I have not done any work on the lathe jet, because I am new and I bought a book [ metal lathe for home machinists] and is all on mm. not on inches. what a fiasco. 4k+ for nothing. HELP

- Joined

- Jan 7, 2016

- Messages

- 3,261

I do not know were to go to express my thoughts on this forums, I am new. I check the lathe today I secure all the bolt and so forth, and on my DRO X went on the lathe from 0 to 0 and check the reading and the sus traction was 700 or 900 sometimes 1000 and sometimes 985, I have not done any work on the lathe jet, because I am new and I bought a book [ metal lathe for home machinists] and is all on mm. not on inches. what a fiasco. 4k+ for nothing. HELP

You might want to start your own thread.

We are all here to help, however, I have no idea what sus traction is. Never heard of that.

The book you purchased is a good book. Yes, it is in MM and not in inches but then again, you are not building from a set of plans.

YouTube is your friend too. A lot of good information.

As I mentioned, start your own thread with more specific questions other than just "help". Also, is English your second language? Not trying to be a jerk, but just wondering.

- Joined

- Nov 27, 2012

- Messages

- 7,852

I do not know were to go to express my thoughts on this forums

You might want to start your own thread.

New thread created.

- Joined

- Nov 27, 2012

- Messages

- 7,852

Sounds to me like the OP might be using a translator or English is not their first language. No matter......

Re: "sus traction". Sounds to me like that should have been "subtraction". From what I make of post #3, sounds like with the dial & dro zero'd, lathe has a .100" dial for the cross slide, one complete revolution of the dial shows an inconsistent reading of .700, .800, .985, etc rather than .100 consistently.

I suspect it's the DRO, possibly the x-axis scale is not installed/adjusted properly (read head to scale gap) or possibly the scales need calibrating. Most DRO displays have this feature. I suspect the former & doubt the latter or possibly the scale is dirty or possibly even defective. OP stated the machine is new but still a possibility.

As I suggested in post #2, quickest way to determine is to set up an indicator & measure travel. That will then tell you if it's the DRO or the dial/leadscrew that is suspect.

Re: "sus traction". Sounds to me like that should have been "subtraction". From what I make of post #3, sounds like with the dial & dro zero'd, lathe has a .100" dial for the cross slide, one complete revolution of the dial shows an inconsistent reading of .700, .800, .985, etc rather than .100 consistently.

I suspect it's the DRO, possibly the x-axis scale is not installed/adjusted properly (read head to scale gap) or possibly the scales need calibrating. Most DRO displays have this feature. I suspect the former & doubt the latter or possibly the scale is dirty or possibly even defective. OP stated the machine is new but still a possibility.

As I suggested in post #2, quickest way to determine is to set up an indicator & measure travel. That will then tell you if it's the DRO or the dial/leadscrew that is suspect.

darkzero you are on it. x-axis when I shake it the x move the reading, I took the the scale out secure all the bolts clean the scale put all back together and still the same. sometimes I move the cross half revolution and the DRO do not move. is there any book or video that I can use.

I will call PM next week to see what they will say.

I will call PM next week to see what they will say.

- Joined

- Nov 27, 2012

- Messages

- 7,852

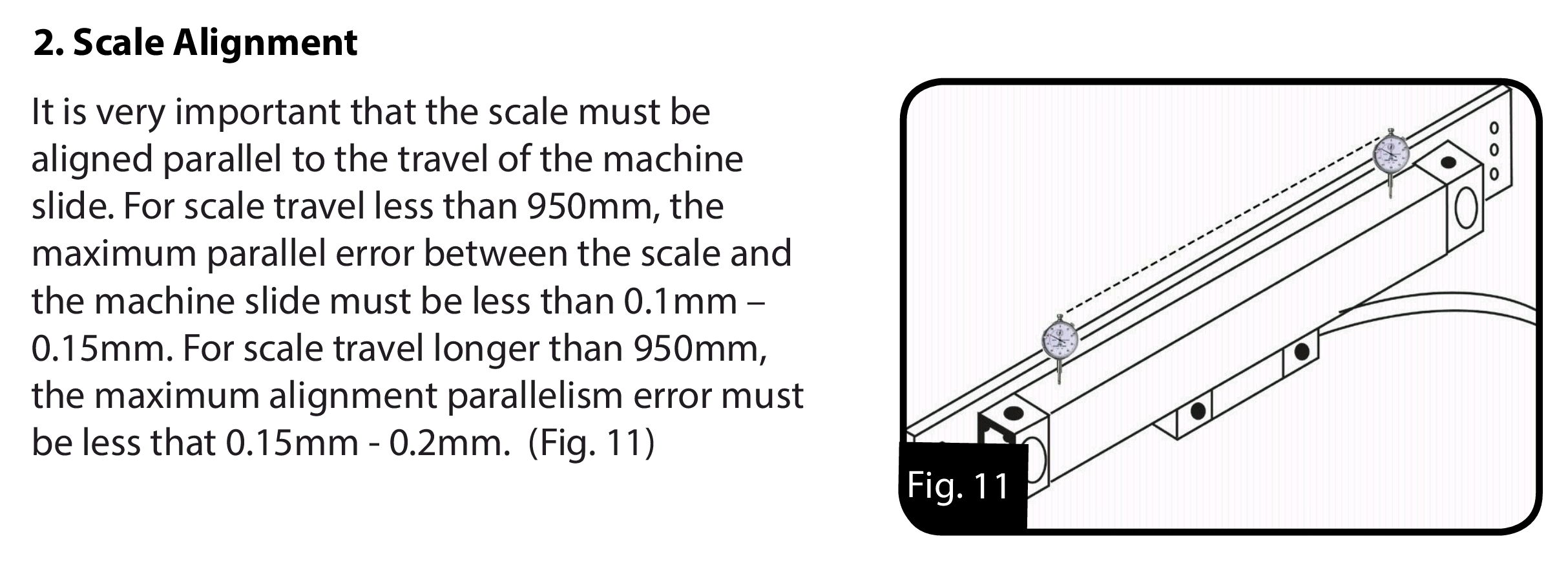

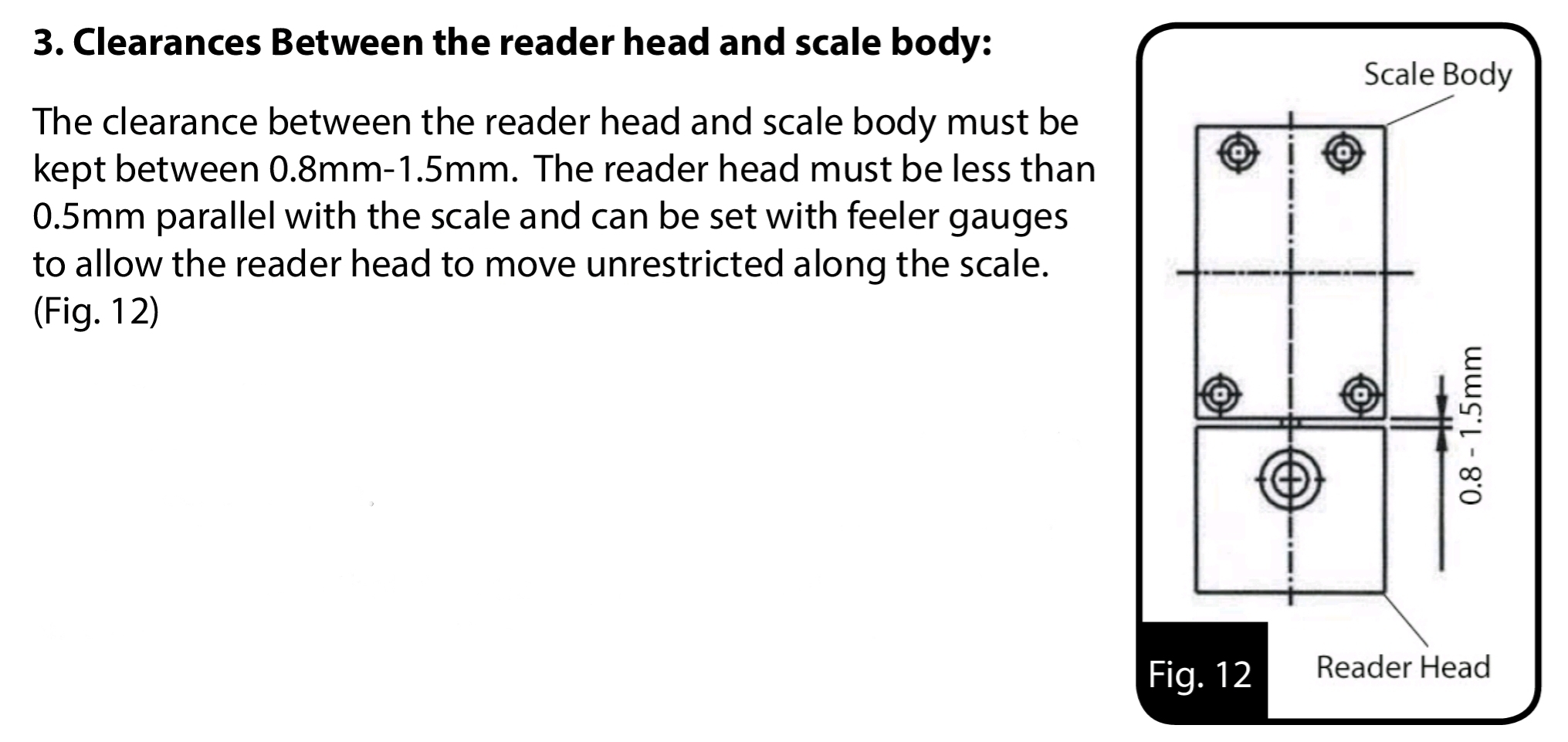

Check the spacing beetween the read head & the scale. The gap should be between .030"-.060" if you have glass scales. Need to make sure the scale is mounted parallel with the axis using an indicator otherwise the read head gap will change as you move the cross slide. The scale being parallel & the read head gap is very important as well as the read head being square with the scale, if not aligned properly it will give erratic readings or none at all like you are experiencing