Anybody out there with the 1236/1340-T have any issues with the OEM Drive Belt? I have consistent small fragments coming off the belt when it runs. Has proper belt tension. I'm leaning more to a poor quality V-Belt as the culprit. What have you guys used as a replacement belt?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM 1236/1340-T OEM Drive Belt Fragments

- Thread starter gman10259

- Start date

- Joined

- Jun 12, 2014

- Messages

- 4,806

Yep, stock belts stink. First thing one needs to do is replace them. I have been using the Gates Tri-Power belt, still on the same belt for 4 years with no discernible wear, belt imbalance or rubber bits flying all over the place. Since they are notched they tend to not take a set and handle the smaller low speed pulley better. You need to purchase both a BX-24 and a BX-25 (at least on the 1340GT), since the stock belt in somewhere in between the two sizes. If you go to a VFD drive you can use a single pulley size/belt. Something in the 2.7-3.0" size and overspeed the stock motor to 90-100Hz. I use an inverter/vector motor so rum my 1340GT to 1800 RPM using a 2.5" pulley with the motor at 125Hz.

Original motor

Inverter motor

Original motor

Inverter motor

Last edited:

- Joined

- Nov 16, 2012

- Messages

- 5,596

Seems about normal. Lot's of dust and clumped-up rubber in the first few months as best I can remember. Power off, engage safties and check for alignment or possibly a burr somewhere. If it all checks-out, tighten them up and check the next time you do a gear change.

As I recall, mine wore out after about 4 years and replaced it with an equivalent sized automotive belt.

Ray

As I recall, mine wore out after about 4 years and replaced it with an equivalent sized automotive belt.

Ray

I have a PM1236 and it has dual belts, seems to be running fine. Belt dust looks normal to me after a few months of regular use. I'm glad it came with dual v-belts. I changed to the high range position and the belts felt good, not too hard. Maybe they will last a long time.

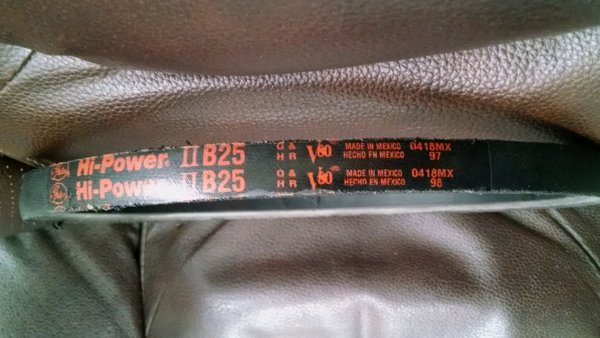

Well I tried Gates HiPower II B25 V belt (Made in Mexico) and had the same shaving issues. Then went with the Gates BX25 (Made in USA) and have had no belt shavings. Thanks for the advice mksj. I have the BX24 on order. mksj in the future I will also be putting a VFD and 3 phase motor on my 1236-T. What brand/size drive did you go with and what brand / spec motor did you use?

Thanks

Thanks

- Joined

- Jun 12, 2014

- Messages

- 4,806

You will need to check the frame motor size dimensions, but I would replace the stock single phase motor with the Marathon 2Hp E467. The motor space is very small, so standard 145 frame TEFC motors will not fit, you need a TENV. Alternate 2 Hp motor is the the Marathon BlackMax and BlueMax Inverter motors, they have a small encoder shaft on the rear of the motor that needs to be cut off. The pulley size depends on a number of different factors, the E467 has a usable speed range of approximately 20-90 Hz, maybe 100, so for a single speed you need something like a 3.0-3.2" pulley going to the larger headstock pulley. The Y526 and Y551 I usually use 20-125 Hz running a 2.4-2.7" pulley going to the larger headstock pulley. You can measure the pulleys and do the calculations, but I usually work it out so at your maximum Hz, your spindle speed in high gear is ~1800 RPM. The sock motor has a 3/4" shaft, the Marathon motors listed have a 7/8" shaft.

The Gates Tri-Power belts seem to work quite well, I have had no detectable belt debris spinning off since I installed them a few years ago. The notched belts work well around smaller pulleys.

I would buy a decent VFD for the lathe and run it in sensorless vector motor control, you will need a braking resistor.

The Gates Tri-Power belts seem to work quite well, I have had no detectable belt debris spinning off since I installed them a few years ago. The notched belts work well around smaller pulleys.

I would buy a decent VFD for the lathe and run it in sensorless vector motor control, you will need a braking resistor.

Attachments

Thanks for the motor data. Are you saying I would need a braking resistor due to the regenerative energy being fed back into the drive bus or for assisting in stopping the spindle?

Thanks again for the advice on the gates BX belts. Hated the mess the regular v belts were making.

Thanks again for the advice on the gates BX belts. Hated the mess the regular v belts were making.

- Joined

- Jul 13, 2014

- Messages

- 1,051

Gman,

Here is one of the earlier VFD conversions with Mark's control system. Did this on my Taiwanese 1236, could very well be from the same factory as yours. I used a Marathon motor, but very tight install, it has been trouble free though and I've used the lathe quite a bit.

https://www.hobby-machinist.com/threads/acer-trump-1236-vfd-conversion.32910/

Here is one of the earlier VFD conversions with Mark's control system. Did this on my Taiwanese 1236, could very well be from the same factory as yours. I used a Marathon motor, but very tight install, it has been trouble free though and I've used the lathe quite a bit.

https://www.hobby-machinist.com/threads/acer-trump-1236-vfd-conversion.32910/