Have been looking at the 1236T and 1340GT. One of the things I noticed was that the 1236T comes with an "economy 3-jaw chuck", but the 1340GT preferred package includes a "ultra high precision 3-jaw chuck" with a TIR of 0.0012 or less. Was wondering what kind of TIR are you seeing on the economy chuck?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM 1236T - What TIR for chuck are you seeing?

- Thread starter ArmyDoc

- Start date

- Joined

- Jun 12, 2014

- Messages

- 4,806

The economy chucks are usually mainland China, the TIR can range quite a bit, the one that came originally with my 1340GT (before they upgraded to Taiwanese chucks) had a TIR of around 0.002-0.003 (but that was a long time ago). You can always take a small cut on the register and use the tap method to get the TIR down and then tighten the chuck. But, TIR you are measuring is typically at one point on the scroll, better chucks will have better linearity across chucking at different sizes. Less expensive chucks typically have 2 sets of solid jaws vs. 2 piece jaws, so this will also introduce more variation on the TIR. You can always upgrade your chuck to the Chandox Set-True Taiwanese 3J scoll with 2 piece jaws that QMT offers as an upgrade. Worth considering if it is your primary chuck.

- Joined

- Apr 23, 2018

- Messages

- 6,509

Money put towards a good chuck is money well spent. If the spindle is the lathe's heart, the chuck is its hands. Steady hands are needed for precision.

- Joined

- May 4, 2018

- Messages

- 143

Good question.

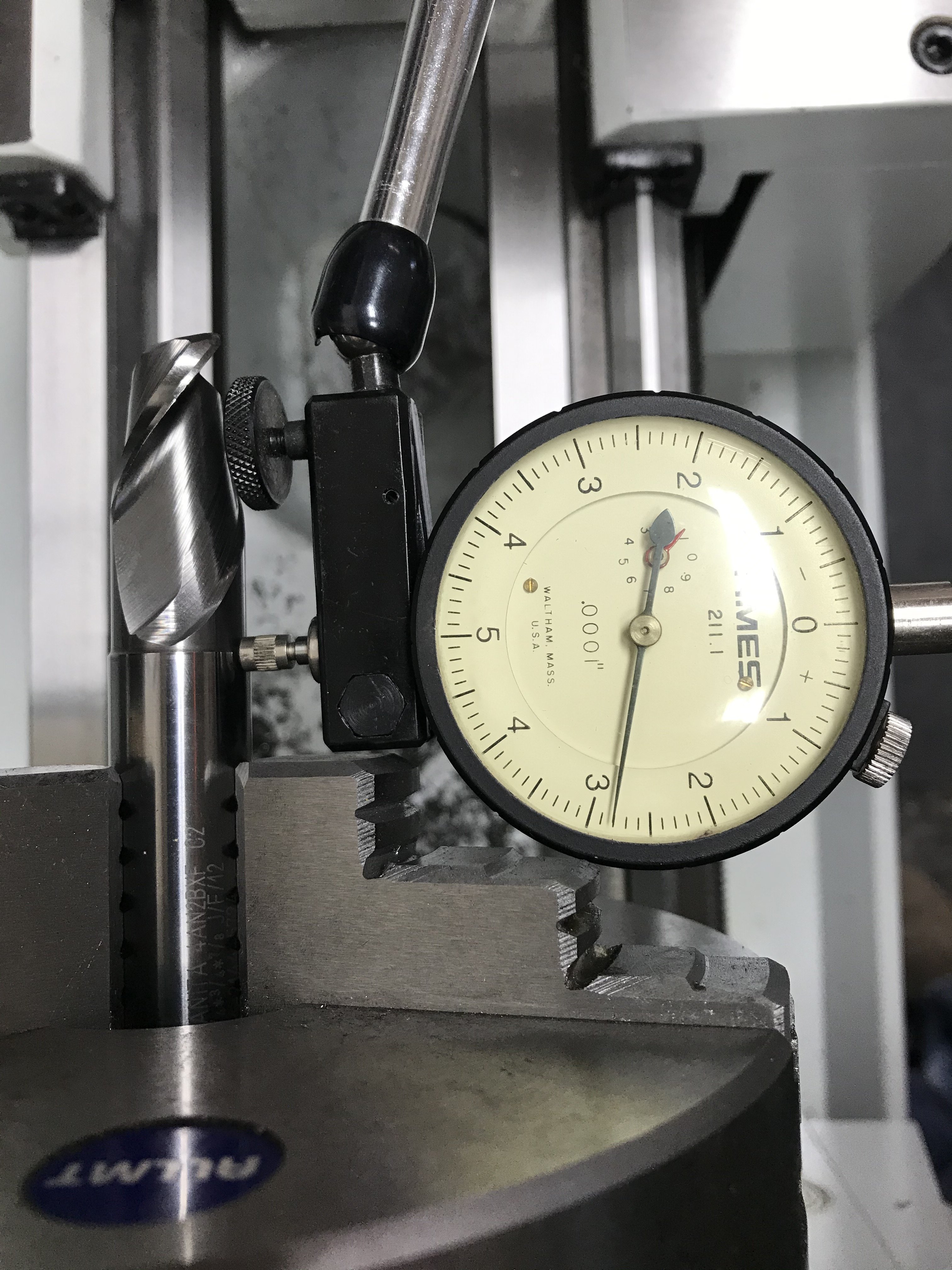

To measure the standard/economy 3-Jaw runout I chucked up a 3/4" Hanita end mill and measured 1/2" from the tip of the chuck jaws. Using my trusty old Ames 0.0001 indicator I measure 0.0028 of runout.

And, this is on my 1236-T which is now a bit over a year old. And, I don't use the 3-jaw chuck much. Mostly I use either a 4-jaw or 5C collets. That's why I didn't upgrade the 3-jaw; don't much care..

To measure the standard/economy 3-Jaw runout I chucked up a 3/4" Hanita end mill and measured 1/2" from the tip of the chuck jaws. Using my trusty old Ames 0.0001 indicator I measure 0.0028 of runout.

And, this is on my 1236-T which is now a bit over a year old. And, I don't use the 3-jaw chuck much. Mostly I use either a 4-jaw or 5C collets. That's why I didn't upgrade the 3-jaw; don't much care..

- Joined

- Mar 25, 2013

- Messages

- 4,613

My spindle runout is not measurable (by me.) Just as a point of reference, my Bison 6" 3 jaw has a runout of between .001 and .002 most positions on the scroll. When I use a 4 jaw I am hard pressed to get below .001 so I usually just use the 3 jaw Bison. Lazy I know!

Robert

Robert

Last edited:

- Joined

- Dec 20, 2012

- Messages

- 9,422

In my opinion, run out on a 3 jaw chuck is immaterial. For first operations work, any 3 jaw is accurate. For second operations work, all 3 jaw chucks are inaccurate (except adjust-tru chucks). What is important is the quality of the chuck. Good chucks have tight fitting scrolls and jaws that move with precision so they grab evenly and solidly. The cost of the chuck is not always a good indicator of good construction; some cheap chucks are well-made. However, really fine chucks generally do cost more.

If I were buying a new lathe, I would just accept the chuck that comes with it; economy is fine. Then I would go and find a really good chuck - a Rohm, Pratt Burnerd, Yuasa, Samchully and it will probably last me the rest of my hobbyist lifetime. If you can afford it and want the ability to dial the chuck in for second operations work, get an adjust-tru chuck. For first op work, you don't need it.

If I were buying a new lathe, I would just accept the chuck that comes with it; economy is fine. Then I would go and find a really good chuck - a Rohm, Pratt Burnerd, Yuasa, Samchully and it will probably last me the rest of my hobbyist lifetime. If you can afford it and want the ability to dial the chuck in for second operations work, get an adjust-tru chuck. For first op work, you don't need it.

I couldn't find that the Set-tru one on their site. I wonder if that is the upgraded chuck that now comes with the 1340GT pref. package. Have sent an e-mail to PM, but haven't heard back yet.The economy chucks are usually mainland China, the TIR can range quite a bit, the one that came originally with my 1340GT (before they upgraded to Taiwanese chucks) had a TIR of around 0.002-0.003 (but that was a long time ago). You can always take a small cut on the register and use the tap method to get the TIR down and then tighten the chuck. But, TIR you are measuring is typically at one point on the scroll, better chucks will have better linearity across chucking at different sizes. Less expensive chucks typically have 2 sets of solid jaws vs. 2 piece jaws, so this will also introduce more variation on the TIR. You can always upgrade your chuck to the Chandox Set-True Taiwanese 3J scoll with 2 piece jaws that QMT offers as an upgrade. Worth considering if it is your primary chuck.

- Joined

- Jun 12, 2014

- Messages

- 4,806

The Chandox Set-True is not listed in QMT's site pick list, there are quite a few items that they stock which are not listed (like Aloris, TMX, etc.), you need to know/ask. As Mikey indicated, if you do a lot of repeat work the set-true chucks work very well, typically TIR is repeatable to 0.0004". There are turning operations on a part that TIR of the chuck does matter when the part is not cut off. There is also a difference in the quality/grind of the jaws which can affect axial skew of the item you are holding. I have a Pratt Burnerd 6.3" Set-Tru 3J that works very well, I feel the Chandox is of similar quality from the ones I have seen. There are a number of tricks to setting up these chucks, also whenever you reverse the jaws, you need to double check the TIR of the chuck. I index these types of chucks to the spindle, so they are always mounted in the same position. I use a collet chuck for anything under 1".

See this post of David Best's Chandox on his 1340GT.

www.hobby-machinist.com

www.hobby-machinist.com

See this post of David Best's Chandox on his 1340GT.

Pm1340-gt Qctp?

I am likely to order a 1340GT later this week when I get it all run to ground. I am trying to decide what to do about a quick change tool post. As you likely know, Matt offers one with 5 holders for ~200 bucks. He also sells a couple of Aloris options but they are far more expensive. Of...

www.hobby-machinist.com

www.hobby-machinist.com

I took delivery of my 1340GT in October. The upgraded chuck is not a "set-tru" style. Like Mark said, they have other items not listed on the website. You just have to ask.I couldn't find that the Set-tru one on their site. I wonder if that is the upgraded chuck that now comes with the 1340GT pref. package. Have sent an e-mail to PM, but haven't heard back yet.