- Joined

- Feb 11, 2020

- Messages

- 29

Anyone have any experience with the taper attachment for the 1340GT?

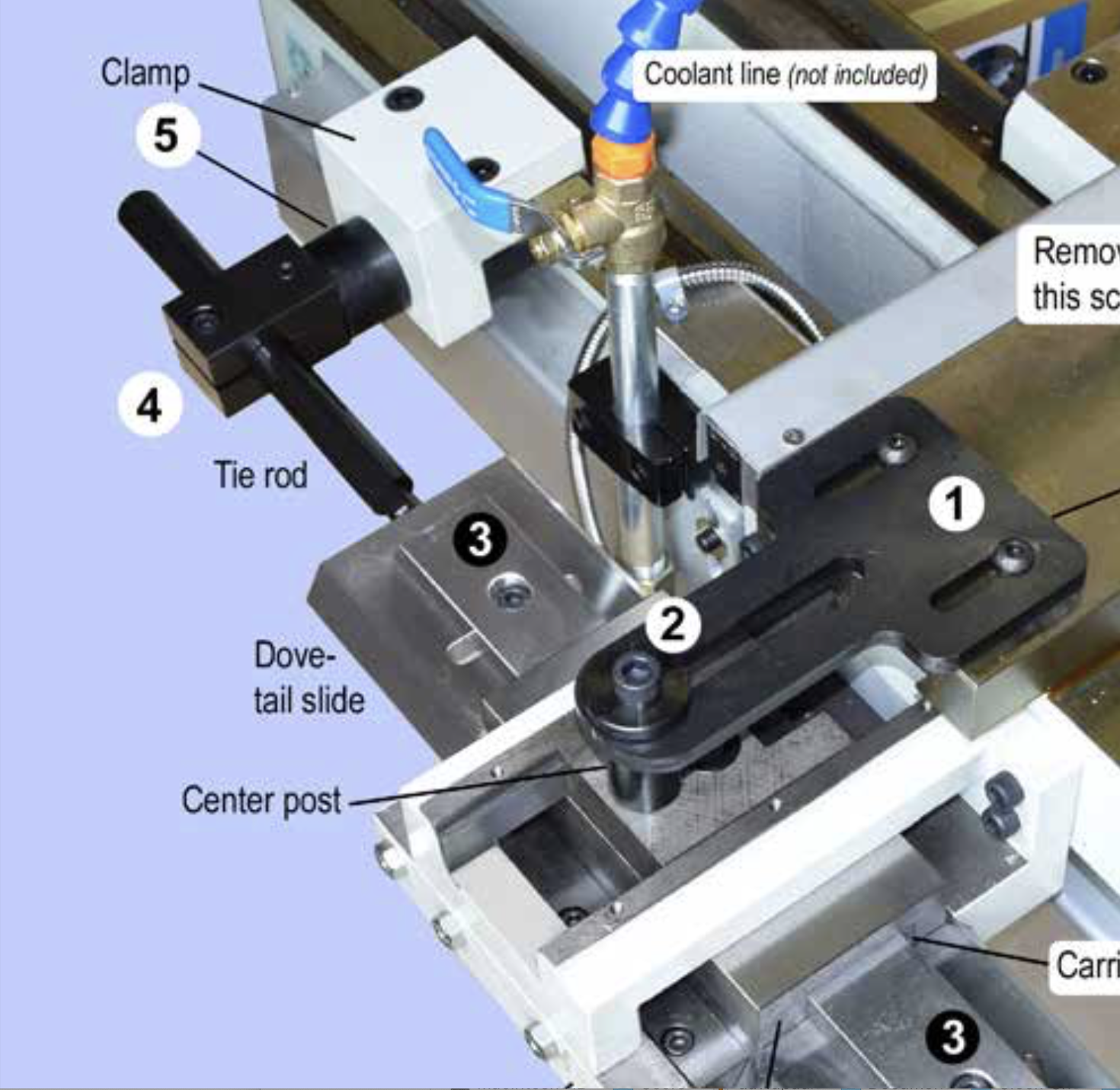

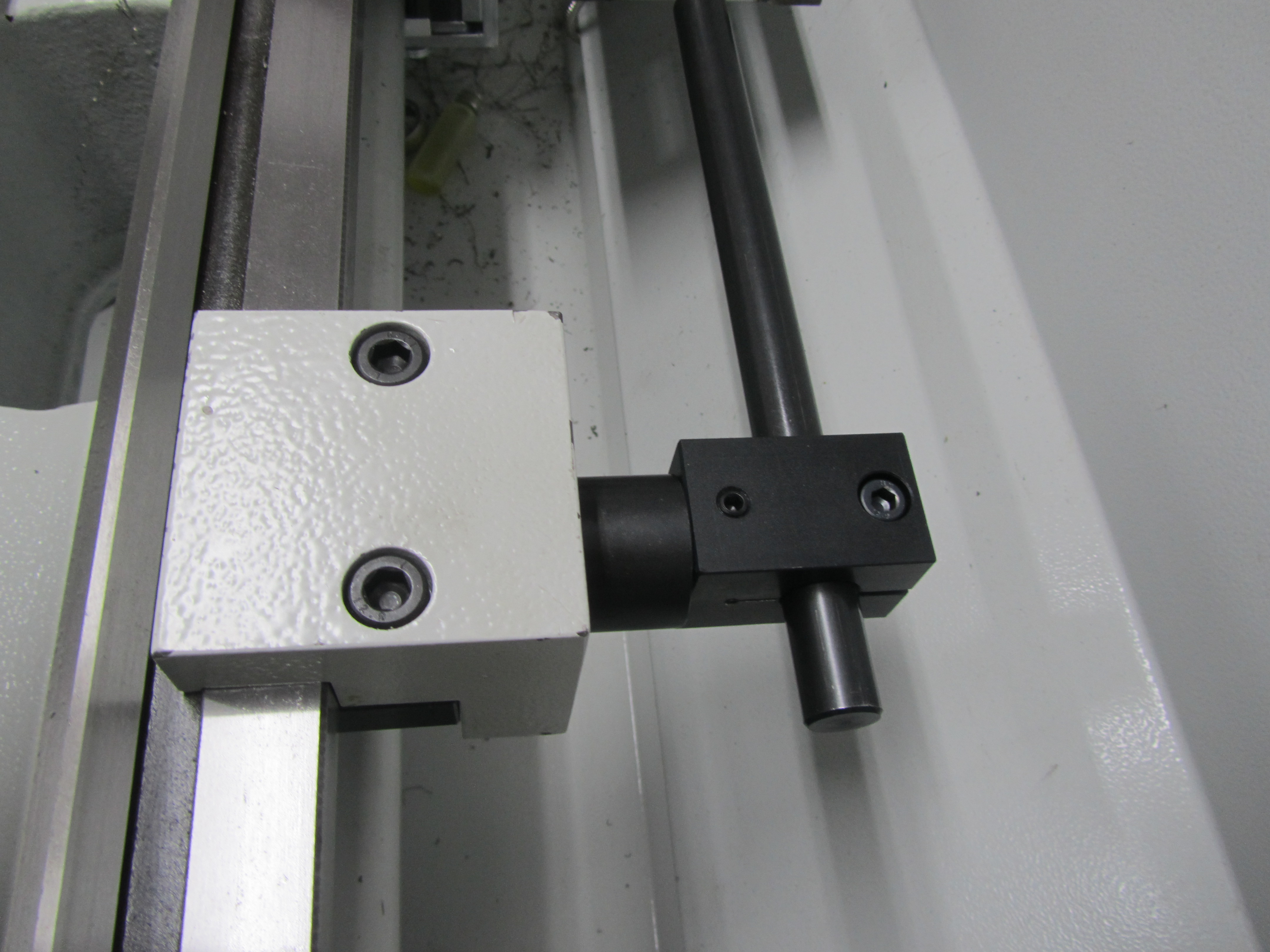

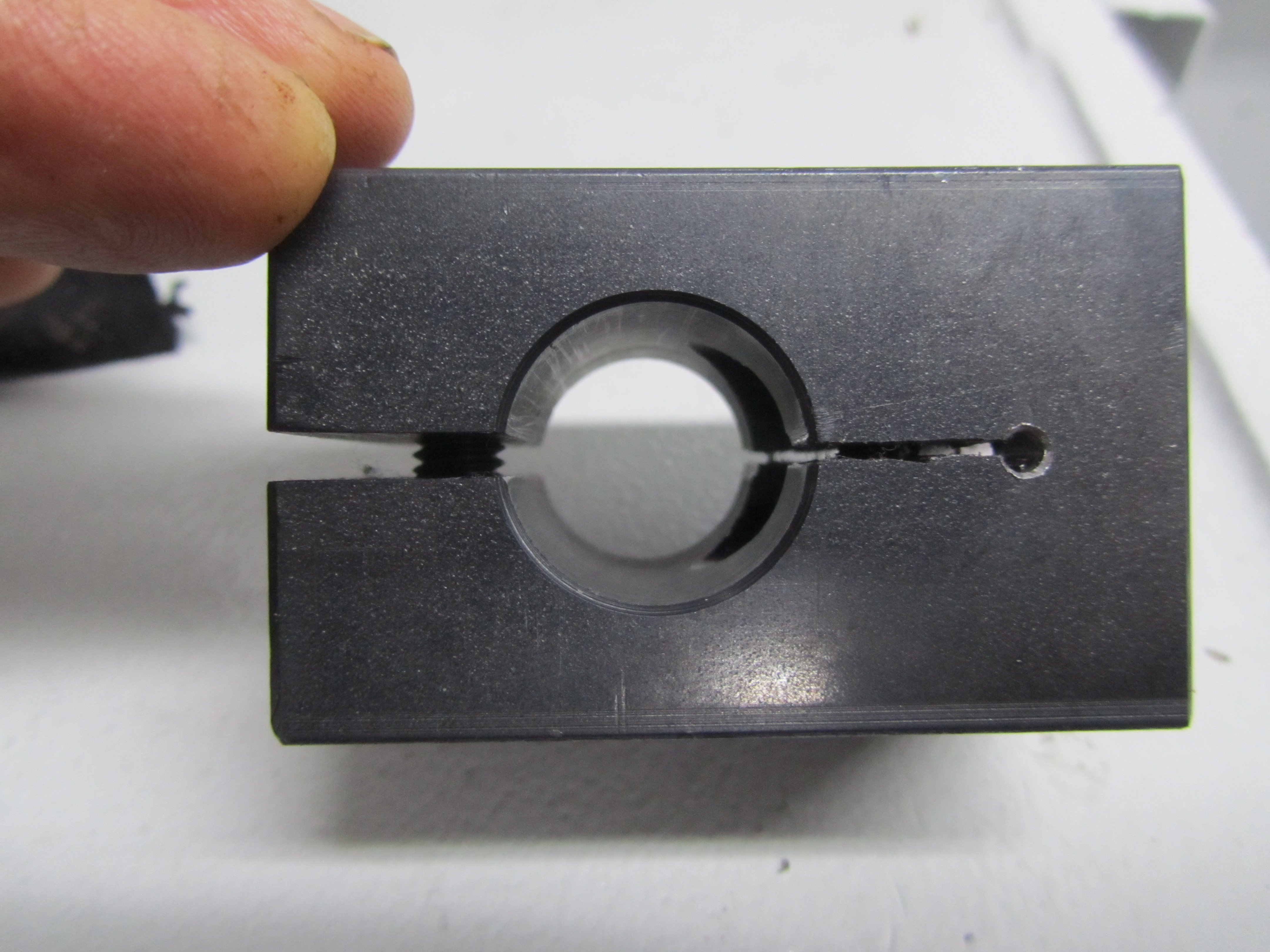

I ordered mine with the lathe. I have installed it according to the instructions. The first problem I discovered was that the outboard tie rod clamp that holds the rod in position could not be tightened down sufficiently to keep it from sliding. Hence it would not anchor the tie rod to the bed of the lathe and the sliding portion of the taper attachment would not function. To remedy this I cut a slot in the back of the clamp with a hole to “check” it and keep it from traveling so to speak. See photos. Now it grips the rod sufficiently to anchor it in position and the sliding portion of the taper attachment moves as the carriage is traversed forward and back. However, after tightening up all the screws, everything seems to be bound up and the cross slide will not budge. And yes, I read the manual and removed the the cross slide leadscrew nut, checked the clearances, gibs, and alignment of the underside of the draw plate where it meets the center post, etc. Everything seems free alone but when I tie it all together nothing moves as it should. Anyone else had experience with this? I must be missing something.

David

I ordered mine with the lathe. I have installed it according to the instructions. The first problem I discovered was that the outboard tie rod clamp that holds the rod in position could not be tightened down sufficiently to keep it from sliding. Hence it would not anchor the tie rod to the bed of the lathe and the sliding portion of the taper attachment would not function. To remedy this I cut a slot in the back of the clamp with a hole to “check” it and keep it from traveling so to speak. See photos. Now it grips the rod sufficiently to anchor it in position and the sliding portion of the taper attachment moves as the carriage is traversed forward and back. However, after tightening up all the screws, everything seems to be bound up and the cross slide will not budge. And yes, I read the manual and removed the the cross slide leadscrew nut, checked the clearances, gibs, and alignment of the underside of the draw plate where it meets the center post, etc. Everything seems free alone but when I tie it all together nothing moves as it should. Anyone else had experience with this? I must be missing something.

David