- Joined

- Nov 28, 2020

- Messages

- 93

Had to remove the table on my mill to tighten up the Y axis lead screw nut. Thread is here if you're curious

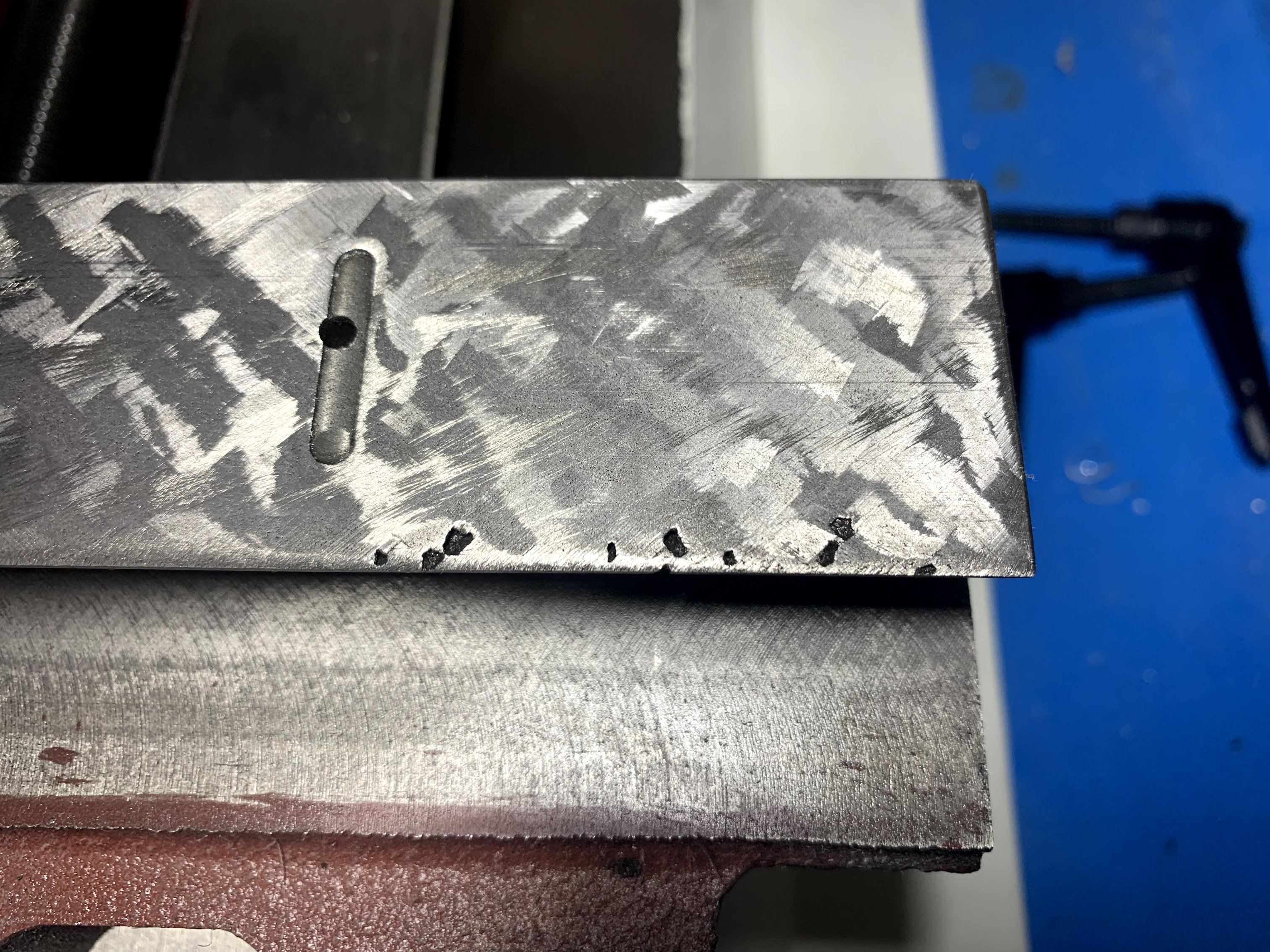

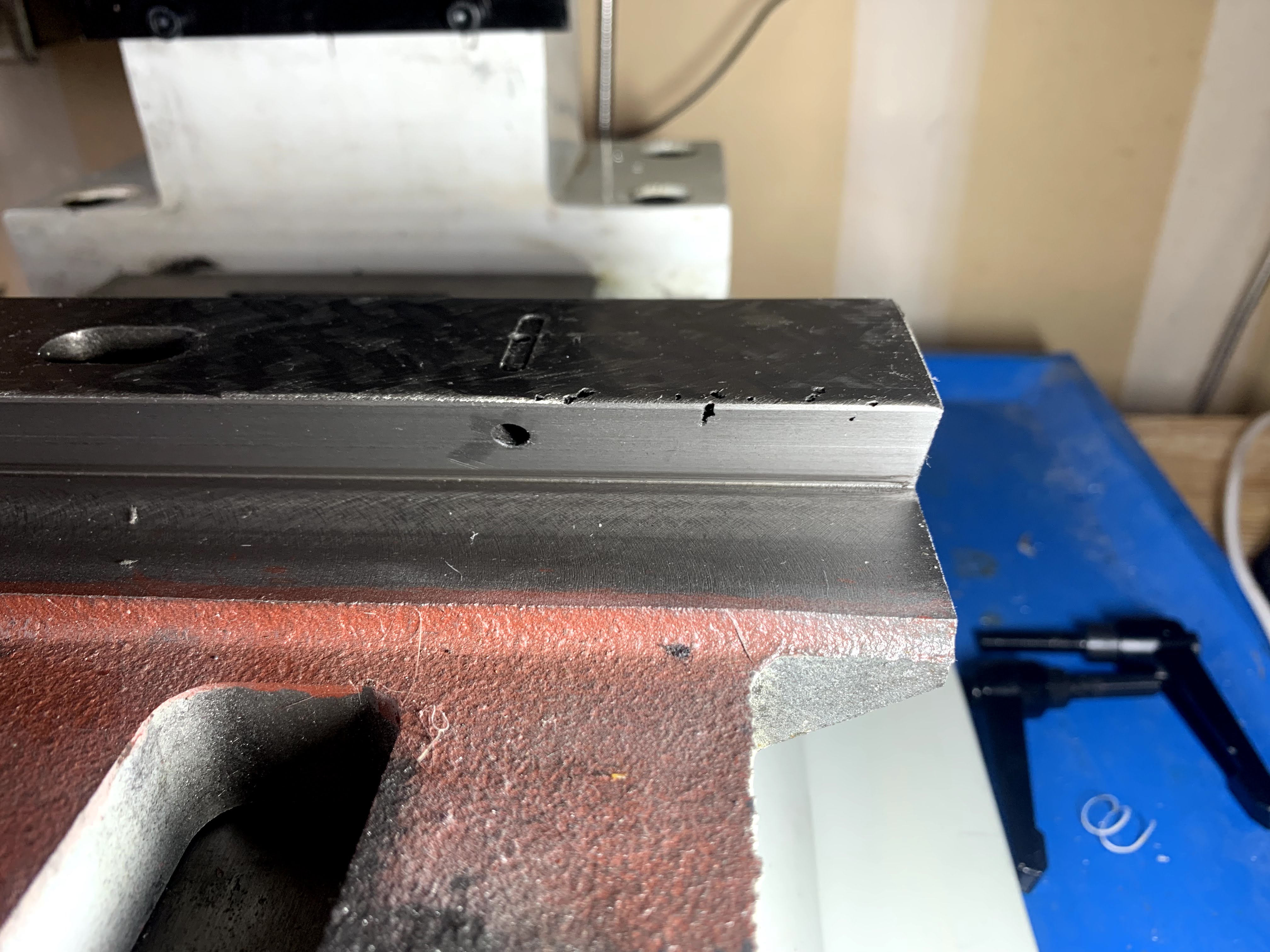

When I got the table off, I found these casting imperfections in the ways on the saddle. I received the machine in Feb 2021, and honestly has barely been used due to me just not having time for it and moving to a new home in May. I'm just now starting to get into it more. I'm rather new to this stuff - I've done a little machine work in the past, but I've never torn a machine down. So I don't know if this is 'acceptable' or something I should be contacting Precision Mathews about and treating it as defective. It doesn't seem like its a huge issue, just a casting defect? But I'm curious what you all think anyway. The table looks fine top and bottom, its just the saddle that seems to be in question.

When I got the table off, I found these casting imperfections in the ways on the saddle. I received the machine in Feb 2021, and honestly has barely been used due to me just not having time for it and moving to a new home in May. I'm just now starting to get into it more. I'm rather new to this stuff - I've done a little machine work in the past, but I've never torn a machine down. So I don't know if this is 'acceptable' or something I should be contacting Precision Mathews about and treating it as defective. It doesn't seem like its a huge issue, just a casting defect? But I'm curious what you all think anyway. The table looks fine top and bottom, its just the saddle that seems to be in question.