I just received my 727m, but I can't set it up until I do some shop construction. I'm not going to be using liquid

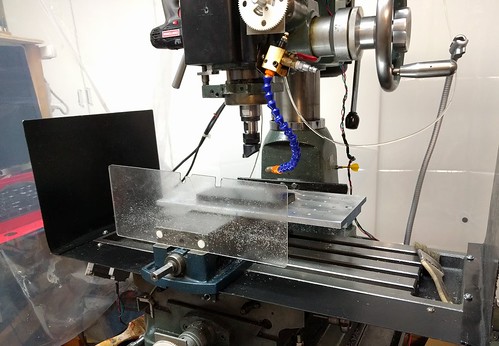

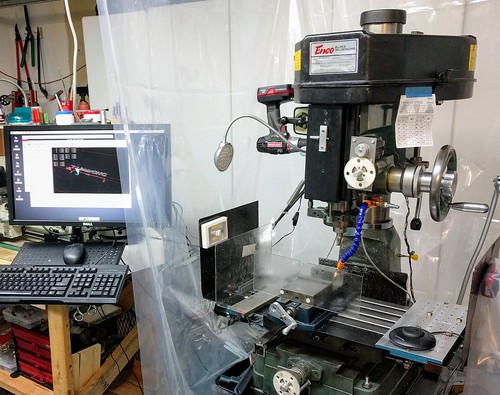

coolant. I would like to contain a lot of the chips if possible. Are there any plans for a simple, cheap, chip enclosure?

Or semi-enclosure, to keep my shop a little cleaner. A full CNC enclosure will not be needed. Thanks

coolant. I would like to contain a lot of the chips if possible. Are there any plans for a simple, cheap, chip enclosure?

Or semi-enclosure, to keep my shop a little cleaner. A full CNC enclosure will not be needed. Thanks