- Joined

- Feb 27, 2020

- Messages

- 36

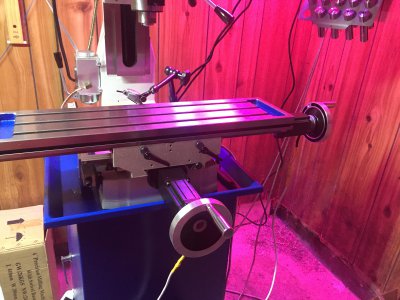

Well I picked up the conversion kit last Monday and overall happy with the kit. I do have some minor complaints about it.

Everything bolted up and fit as it should. I wasn’t disappointed with the cast iron bearing blocks and motor mounts and they justified the 8 month wait for this kit.

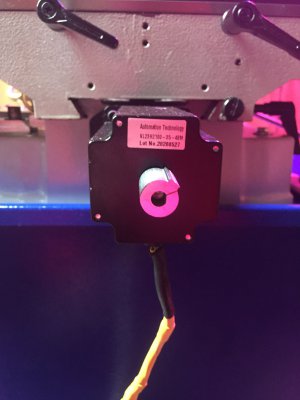

I ended up getting some cheap Nema 23 570oz dual shaft steppers instead of trying to fit the 34’s I already had. I made some adapters for the shafts to work since they were 1/4” also I could still use the hand wheels. That’s when I noticed something was off.

The Y axis ballscrew is the same hand thread as the X axis! Therefore the Y axis moves in the opposite direction as it normally would. This was disappointing, I took the extra effort to still have hand cranks but can’t really use them.

The other thing that wasn’t so great was I have approximately .001” backlash in X and .003 in Y. Not sure if it’s on the ballnut or if it on the shaft coupler. I welcome any suggestions on remedying this. I can’t pickup any axial play on the shaft.

Other than those two things, I’m happy with the kit. I haven’t installed the Z axis yet. I wanted to have it somewhat of a manual mill with contouring capabilities for now.

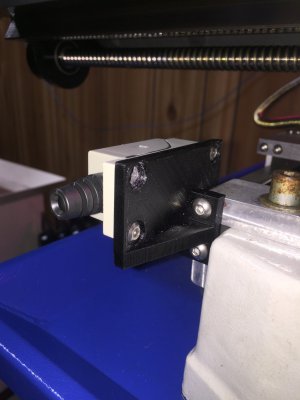

I’ll post some pictures of the adapters I made when I get a chance. Also when I get my limit switches mounted. I printed up some brackets and need to test fit before I make them out of aluminum.

Also printed a little wrench to snug up the lock nuts.

Everything bolted up and fit as it should. I wasn’t disappointed with the cast iron bearing blocks and motor mounts and they justified the 8 month wait for this kit.

I ended up getting some cheap Nema 23 570oz dual shaft steppers instead of trying to fit the 34’s I already had. I made some adapters for the shafts to work since they were 1/4” also I could still use the hand wheels. That’s when I noticed something was off.

The Y axis ballscrew is the same hand thread as the X axis! Therefore the Y axis moves in the opposite direction as it normally would. This was disappointing, I took the extra effort to still have hand cranks but can’t really use them.

The other thing that wasn’t so great was I have approximately .001” backlash in X and .003 in Y. Not sure if it’s on the ballnut or if it on the shaft coupler. I welcome any suggestions on remedying this. I can’t pickup any axial play on the shaft.

Other than those two things, I’m happy with the kit. I haven’t installed the Z axis yet. I wanted to have it somewhat of a manual mill with contouring capabilities for now.

I’ll post some pictures of the adapters I made when I get a chance. Also when I get my limit switches mounted. I printed up some brackets and need to test fit before I make them out of aluminum.

Also printed a little wrench to snug up the lock nuts.

Attachments

-

37C07D57-6F4F-44EA-B9EF-80E0023397CE.jpeg1.7 MB · Views: 20

37C07D57-6F4F-44EA-B9EF-80E0023397CE.jpeg1.7 MB · Views: 20 -

576403A0-9221-40F3-A384-586F825AA8F8.jpeg989.2 KB · Views: 15

576403A0-9221-40F3-A384-586F825AA8F8.jpeg989.2 KB · Views: 15 -

C402F026-169C-4201-965F-CD80C197B45E.jpeg780.7 KB · Views: 20

C402F026-169C-4201-965F-CD80C197B45E.jpeg780.7 KB · Views: 20 -

FE80DF11-7164-41D9-A31D-EA717CF204CD.jpeg2.2 MB · Views: 20

FE80DF11-7164-41D9-A31D-EA717CF204CD.jpeg2.2 MB · Views: 20 -

96D2B3FA-98FB-4A85-A48D-5CC185A604DD.jpeg1.8 MB · Views: 22

96D2B3FA-98FB-4A85-A48D-5CC185A604DD.jpeg1.8 MB · Views: 22

Last edited: