- Joined

- Sep 22, 2019

- Messages

- 89

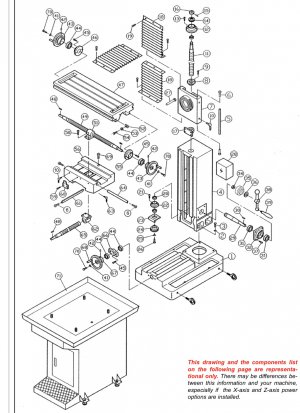

I am having problems correcting the Y axis backlash. PM tech support suggested tightening the split-nut screw and tightening the split-nut mounting bolts.

After a lot of trial and error I was able to tighten the split nut screw to the point that it was hard to turn the crank handle. There was no affect on the backlash.

Getting to that screw was difficult to say the least. I used a 1/4" drive ratchet, a mirror, and a flashlight. String was attached to the flashlight and wrench.

The mounting bolts for the split nut could not be tightened any further.

For all my effort the backlash is a little worse than when I started.

Does anyone have any suggestions?

Below is a link to a YouTube video:

After a lot of trial and error I was able to tighten the split nut screw to the point that it was hard to turn the crank handle. There was no affect on the backlash.

Getting to that screw was difficult to say the least. I used a 1/4" drive ratchet, a mirror, and a flashlight. String was attached to the flashlight and wrench.

The mounting bolts for the split nut could not be tightened any further.

For all my effort the backlash is a little worse than when I started.

Does anyone have any suggestions?

Below is a link to a YouTube video: