- Joined

- Jan 16, 2016

- Messages

- 302

One of the best mods i did to my pm-833t was to add a positive quill stop .

The factory item is totally inadequate and moves every time you tap it .

What i came up with was way overbuilt and visually in the way .

The new version is greatly streamlined.

I managed to score a Mitutoyo quill kit for a Bridgeport and have

spent a year thinking about the best way to install it on the pm mill .

These things are in the way all over the place on a Bridgeport .

So i wanted to keep it more ergonomic than the typical installation .

They also move with the quill all the time even when not in use .

So here is what i came up with .

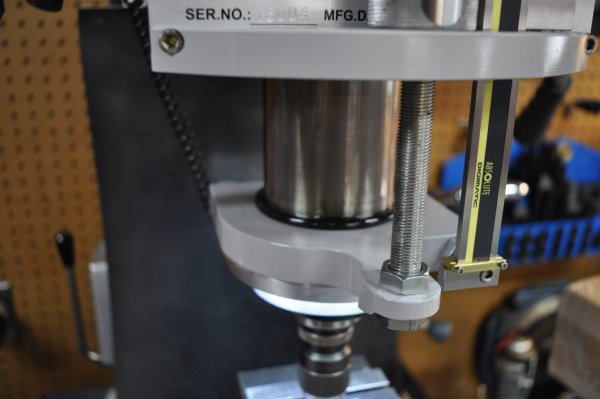

My stop collar is a two piece design & works like a clamp on the quill .

It is secured by two 1/2-20 bolts on the back & holds the quill stop rod quite solidly .

There is a "shelf" attached to the front of the mill for the intelligent nut to bump against .

On the new version i added a slot for the quill readout scale to go through .

The read head is mounted to a plate that is attached to the front plate on the mill .

This plate covers the original now unused quill stop hole & scale .

None of this obstructs the serial # & manufacture date on the mill

i made a small brass clamp for the end of the scale that holds a magnet .

This magnet can be stuck to a steel block that mounts on the moving collar

so the scale rides up and down with the quill .

It also can be lifted and stuck to the bottom of the shelf when the quill readout is not in use !

I am so happy with the way this turned out that i wanted to share .

The factory item is totally inadequate and moves every time you tap it .

What i came up with was way overbuilt and visually in the way .

The new version is greatly streamlined.

I managed to score a Mitutoyo quill kit for a Bridgeport and have

spent a year thinking about the best way to install it on the pm mill .

These things are in the way all over the place on a Bridgeport .

So i wanted to keep it more ergonomic than the typical installation .

They also move with the quill all the time even when not in use .

So here is what i came up with .

My stop collar is a two piece design & works like a clamp on the quill .

It is secured by two 1/2-20 bolts on the back & holds the quill stop rod quite solidly .

There is a "shelf" attached to the front of the mill for the intelligent nut to bump against .

On the new version i added a slot for the quill readout scale to go through .

The read head is mounted to a plate that is attached to the front plate on the mill .

This plate covers the original now unused quill stop hole & scale .

None of this obstructs the serial # & manufacture date on the mill

i made a small brass clamp for the end of the scale that holds a magnet .

This magnet can be stuck to a steel block that mounts on the moving collar

so the scale rides up and down with the quill .

It also can be lifted and stuck to the bottom of the shelf when the quill readout is not in use !

I am so happy with the way this turned out that i wanted to share .