- Joined

- Jun 27, 2019

- Messages

- 109

OK.Pictures?

Sorry it's a bit untidy. I have just been working on my VFD install on my PM-835S mill.

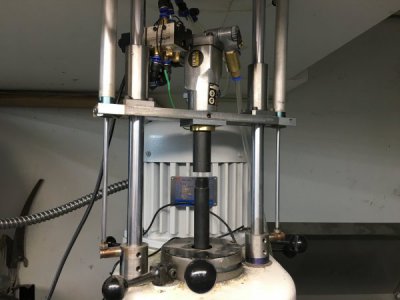

What you can see are the twin pneumatic cylinders (150mm long) needed to handle the full travel of the quill. The picture shows the drawbar at the top of its travel. Normally the cylinders hold up the butterfly ratchet assembly clear of the drawbar. When depressurized by pressing on one of two control panel buttons, the entire assembly quickly lowers on the 20mm linear bearings until the impact socket hits and engages with the hex of the drawbar. This works even if the quill is fully extended as the deep impact socket is small enough to drop through the hole and reach the drawbar. Either push button releases the pneumatic cylinders via a 12v valve and a pair of diodes.

Until this point no air has reached the ratchet as there is a 12v valve controlling it. When the impact socket hits the drawbar, the socket is pushed upwards against the brass ring (you can see the green contact wire in the photo below) and an electrical connection is made between power supply, ring, socket, drawbar and mill body. This turns on the air supply to the ratchet, tightening or loosening the drawbar depending upon which of the two buttons was pressed. Air is diverted by a two-way valve to whichever wrench port is needed to tighten or loosen. Needless to say the brass ring is electrically insulated from the metal that surrounds it.

It did require quite a bit of tuning of air pressures and other adjustments to get it to work, but work it does. I did consider many alternatives including an air pressure sensor rather than the brass ring contact, but this scheme worked best.

I would love to hear of another, more elegant solution to the problem as it isn't the prettiest aspect of the mill, but unless I could grow about 6 inches taller I was faced with a step ladder being a standard part of my milling tool set.