When the stepper "spun but the table never moved at all" you where missing steps. In my experience a stepper won't miss just one step or micro step, it misses all the steps until the speed becomes low enough that it can actually get going again. Remember, if the motor misses a step, that means it basically stopped for an instant, but the controller is still driving it at what ever speed it was at when it missed the step, which means you essentially have unlimited acceleration. Think about it like this, you're on a train that is moving, and you fall off, you're not going to be able to get back on that train until it slows to the point you can catch it. So that sound you heard was the stepper trying to rotate, but not actually rotating (missing steps).

Hope this makes sense.

PZ

Hi PZ,

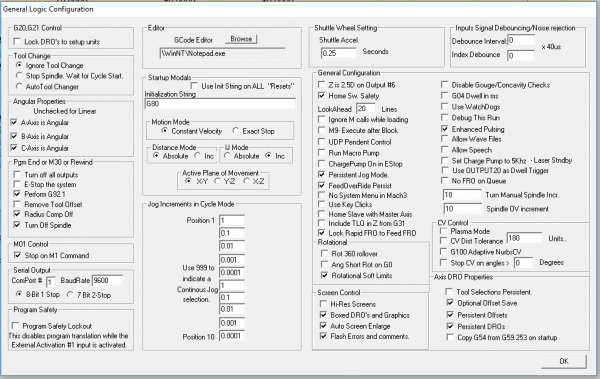

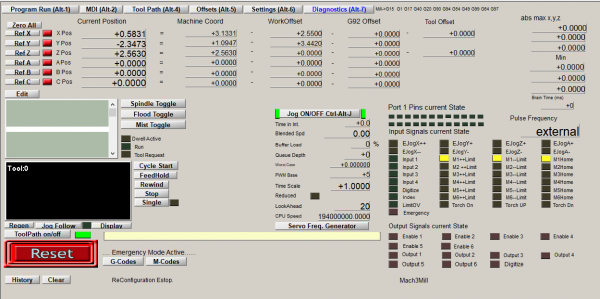

I understood that the sound was of the stepper missing all the steps, I was confounded as to what velocity and acceleration I must have inserted in the the motor tuning to cause it. I was incrementally increasing the Vec and Accel to see when I would start missing steps and then suddenly I must have gone way overboard on the settings (operator error). Maybe I typed in the Accel at a value significantly higher than 40in/sec-sec. That would do it for sure, but I should have caught this. Anyway, when this happened I set the Accel back to the factory setting of 20in/sec-sec. and started my measurements over.

Forgive me for writting the stuff below. I just wanted to work through it for my own thought processes.

Some simple math. For a given acceleration setting, I want to determine the travel distance before reaching the terminal velocity (V1, velocity as set in the motor tuning configuration page) is reached. Assume: X=distance, Xo=initial starting location (Xo=0), V=velocity as a function of time (initial velocity is zero), A= the acceleration (constant value as set in the motor tuning), t = time, at time t1, the terminal velocity, V1, is reached. So the position during acceleration is described by X-Xo=0.5A

t^2. The instantaneous velocity during the acceleration period (time 0 until t1) is simply V(t)=dx/dt=At. So t1 can be obtained by solving for where V(t1)= V1. So t1=V1/A. (simple) So the distance traveled to reach terminal velocity is X(t1)-Xo= .5A

t1^2. Now lets assume the motor tuning values of V1 to be 120 in/minute and A to be 40 in/sec-sec. Use 60 second in a minute. Then t1=V1/A=(120/60)/40 =2/40 = 0.05 seconds. This then corresponds to a distance of X(t1)-Xo= .5At1^2=.5

400.05^2=0.05 inch. In other words, the stage only has to travel 0.050 inches before reaching the terminal velocity and so get out of the acceleration process. From a visual perspective, the acceleration to the terminal velocity is essentially instantaneous and difficult to distinguish for moves of any common length!

So my motor tuning logic is: Keep the acceleration value low so that steps are not lost during the period when the motor has to exert the most force to over come the inertia of the mass of the stage+vise+work piece. (During the constant velocity portion of a x or y move, in concept, the motor only has to over come the friction of the stage. During the constant velocity of the z stage it must over come both the friction and the gravitational weight.) In the motor tuning set up that I recieved from the factory, the x,y,z acceleration values were all set the same at 20in/sec-sec while the terminal, x, y, z, velocities were set at 40, 30, and 20, respectively.

By the way, a "g" is 9.8meter/sec-sec or 385.8 in/sec-sec, so when Mach shows 40in/sec-sec for the acceleration this corresponds to 0.103 g's , so is only 10% of the g from gravity for moves in the z direction! Clearly the 940M can lift the z stage's 250 #s of weight. So the z-axis stepper, which is a little larger than the x and y steppers, can carry a force associated with more than 1 g. So most of the above discussion seems almost irrelevant.

However, there is another part of physical mechanics which is less talked about in the physics text books. Rather than just dynamic friction it is static friction, sometimes called stiction and the extension of this being stick-slip-stick-slip... process. When an object sits for a while on a surface it tends to stick to it due to molecular bonding. This would especially be true for the x and y stages where with the full weight of the stages setting stationary the weight would tend to spread the oil out or push it out totally yielding a bond between the stage and the ways. Breaking this loose initially can take much more force than just discussed. However, this would be another reason to set the tuning acceleration to a lower value... give the stepper a little more time to break the stiction and get the stage up to speed. I suspect that this is less critical on the z-axis due to the weight of the head tilting the contact (wedge) at the ways. The bottom corners of the ways will have a lot of pressure between the parts while the top will have little to nothing.

Dave