- Joined

- Jun 12, 2014

- Messages

- 4,808

Normally I do not like to do full VFD build systems, they take way too much time and cost. But I was asked to do two full system builds one for a PM-949TS mill and an second for PM-1440GT lathe. I kinda of caved, figuring I hadn't done builds for either machine and I wanted to see what I could be be built for both. This is the a review of the PM-949TS mill build. First there was the wish list which grew over time, I started out with thinking I would build a basic control board build and then the auto reverse for threading would be nice, and also a back gear sensor to reverse the VFD inputs when engaged. I decided to build the full system as a plug and play because there were just too many variables in the build process that needed to be addressed. The other major challenge that was also requested by another PM-949TS owner was developing a low profile spindle tach system, and I decided to also included a LED Halo light built into the tach sendor ring.

The Tach/Halo LED light needed to be have a very low profile magnetic NPN pickup, the one I chose is only and 1/8 thick by 0.30" wide. I turned a light ring assembly out of 4.25" aluminum stock, which slides up on the ram and extends below the ram about 1/4". The NPN pickup sensor is fitted between this 1/4" and all the wiring brought out through the back of the ring. A small set screw holds the rings in place. I normally embed the a neodymium magnet into the aluminum spindle ring, but it did not work in this case. This NPN sensor has a very short sense range (like 0.050" or less), so I embedded the magnet on the outside of the ring with a very narrow gap between it and the sensor. I milled an outer ridge so the Halo LED snaps on, but also attached it with some silicone sealant to prevent oil contamination. Some pics as follows:

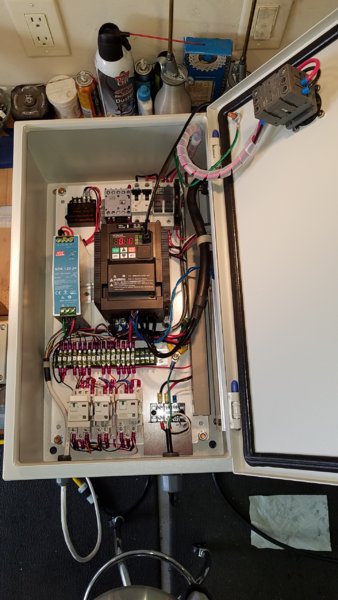

The mill control system was a new ground up design as it was a total build, I did use some of the design and features that I incorporated into my knee mill. I use proximity sensors to detect the back gear, so forward is always forward, and a second proximity sensor which triggers an auto reverse for threading. On my mill this is triggered by the spindle stop adjustment ring, I also have an auto start function. In this build we decided to put the following controls in a knee mounted pod, stop, run, forward/reverse, auto reverse, and coolant (with indicator lights for each function). The E-Stop, tachometer and speed control are mounted in a enclosure mounted to the mill head. I used a precision 3 tun speed pot which gives very fine motor control which is set to operate from 20-120 Hz on the 4 pole motor wiring. I used heavy diecast aluminum enclosures, and also polished the unpainted mill head enclosure face. The main VFD enclosure, I decided to go with a larger 20x12x8 NEMA 4X/12 cabinet, so I would not need any vents or fans. It also includes a main power disconnect, VFD fusing, breaker for a dual gang 120V box, brake resistor, 120W 24VDC power supply with 12VDC step-down converter and control system. Everything fit nicely, although a lot of wiring. When completed it ended up working as designed, which made me happy. It was a 3 week build, plus development and sourcing parts. Needless to say I will not be building another one of these systems.

Building the VFD/system control board.

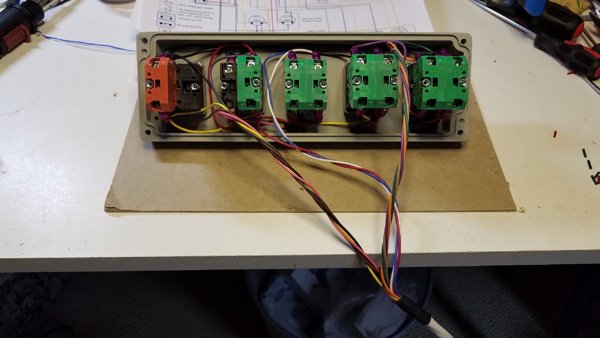

Mounting the electrical box and 120VAC sockets

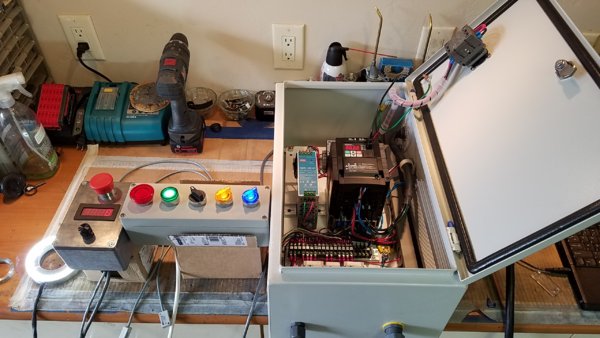

Control Pods (including the smaller one which is for the 1440GT)

Programming the VFD and bench testing. The two proximity sensors are the small squares attached to the cables. All the control and motor cables are shielded, and a star ground is used on the back plate.

Next will be the 1440GT VFD system build, along with a basic VFD conversion for the PM-1440GT which uses the stock control board.

The Tach/Halo LED light needed to be have a very low profile magnetic NPN pickup, the one I chose is only and 1/8 thick by 0.30" wide. I turned a light ring assembly out of 4.25" aluminum stock, which slides up on the ram and extends below the ram about 1/4". The NPN pickup sensor is fitted between this 1/4" and all the wiring brought out through the back of the ring. A small set screw holds the rings in place. I normally embed the a neodymium magnet into the aluminum spindle ring, but it did not work in this case. This NPN sensor has a very short sense range (like 0.050" or less), so I embedded the magnet on the outside of the ring with a very narrow gap between it and the sensor. I milled an outer ridge so the Halo LED snaps on, but also attached it with some silicone sealant to prevent oil contamination. Some pics as follows:

The mill control system was a new ground up design as it was a total build, I did use some of the design and features that I incorporated into my knee mill. I use proximity sensors to detect the back gear, so forward is always forward, and a second proximity sensor which triggers an auto reverse for threading. On my mill this is triggered by the spindle stop adjustment ring, I also have an auto start function. In this build we decided to put the following controls in a knee mounted pod, stop, run, forward/reverse, auto reverse, and coolant (with indicator lights for each function). The E-Stop, tachometer and speed control are mounted in a enclosure mounted to the mill head. I used a precision 3 tun speed pot which gives very fine motor control which is set to operate from 20-120 Hz on the 4 pole motor wiring. I used heavy diecast aluminum enclosures, and also polished the unpainted mill head enclosure face. The main VFD enclosure, I decided to go with a larger 20x12x8 NEMA 4X/12 cabinet, so I would not need any vents or fans. It also includes a main power disconnect, VFD fusing, breaker for a dual gang 120V box, brake resistor, 120W 24VDC power supply with 12VDC step-down converter and control system. Everything fit nicely, although a lot of wiring. When completed it ended up working as designed, which made me happy. It was a 3 week build, plus development and sourcing parts. Needless to say I will not be building another one of these systems.

Building the VFD/system control board.

Mounting the electrical box and 120VAC sockets

Control Pods (including the smaller one which is for the 1440GT)

Programming the VFD and bench testing. The two proximity sensors are the small squares attached to the cables. All the control and motor cables are shielded, and a star ground is used on the back plate.

Next will be the 1440GT VFD system build, along with a basic VFD conversion for the PM-1440GT which uses the stock control board.