- Joined

- Mar 26, 2018

- Messages

- 8,397

No,Anything new with your build?

I haven’t got back into it.

It may wait until I retire. Now that I touched my toe into the model making hobby, I see how much time it takes to do a proper build.

No,Anything new with your build?

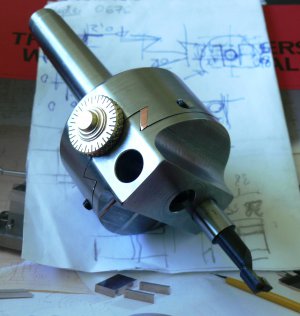

I'd like to see your home made boring head.After messing around with my small mill and a selfmade boring head The second model cylinder I made on my lathe. It was much easier and had a better surface finish. So it depends on your machines

I had the same problem with my #3, it WORKED, but only slightly so as things were quite a bit too small for my machines. My hit-miss engine was even worse for that, I had a couple of parts i didn't make well enough, so that engine is basically in the junk pile having never run.I'd like to see your home made boring head.

The cylinders are tricky. I made a comment to Joe Pie. at Advanced Innovations _Youtube-, He asked me why they were challenging??

I said, because the castings are irregular, there is no point to measure from and so on.

He then went on to build a steam engine kit by PM.

If you watch Keith Appleton, Learning Turning and Joe Pieczynski, you'll see three methods of turning cylinders.

I believe they all got there in the end but went about it very differently.

I think if I get back into these models I'll buy a larger kit. The #7 was not a good choice for my equipment.

You guys have to try a #4 or #6. The parts are decently sized and there are very few tiny parts to be made. It is a lot of work but very enjoyable.I had the same problem with my #3, it WORKED, but only slightly so as things were quite a bit too small for my machines. My hit-miss engine was even worse for that, I had a couple of parts i didn't make well enough, so that engine is basically in the junk pile having never run.

)

)

True, but changing out a 10" 4 jaw chuck is a royal PITAI have often heard “you can build small things on a big lathe but you can’t build big things on a small lathe”.

An 8" chuck is a PITA. Couldn't imagine a 10".True, but changing out a 10" 4 jaw chuck is a royal PITA

I've got a 12" 3 jaw that I used to use an engine hoist to get into place! Fortunately I replaced it with a 8" 6 jaw and use THAT for just about everything (plus an 8" 4 jaw), otherwise chuck changes would be near-impossible.An 8" chuck is a PITA. Couldn't imagine a 10".