As I did not want to hijack Morgan RedHawk “Holy cow, my PM1236 shipped!”</SPAN>

located here:</SPAN>

http://www.hobby-machinist.com/showthread.php?t=22392</SPAN>

I am starting new thread of PM1236 lathe Compound Slide Dial.</SPAN>

Will. Thank you for your spectacular documentation of your PM1236 Lathe dials, and here are my results. I think I ordered my PM1236 right after you as I recall your postings and attempted to do a lot modifications you did. I purchased my PM1236 in March 2011.</SPAN>

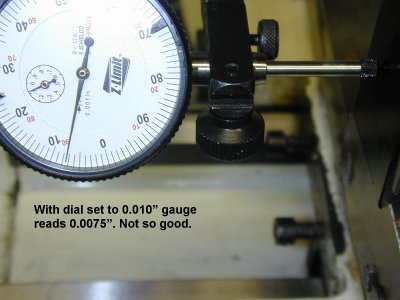

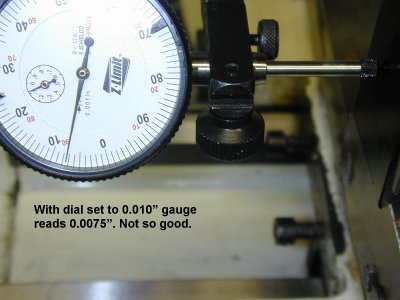

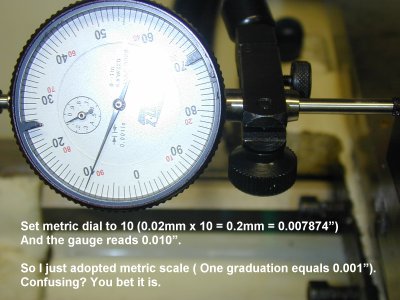

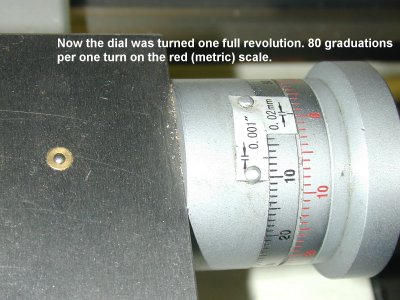

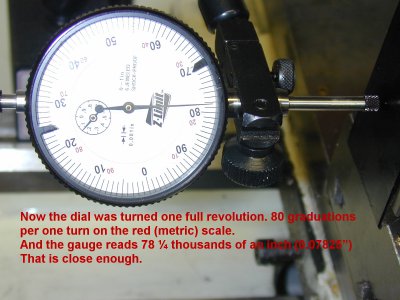

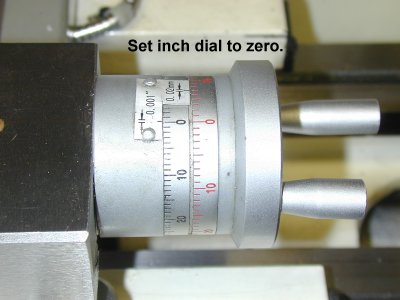

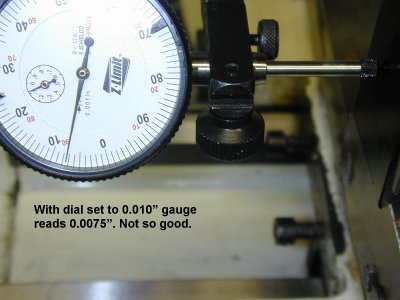

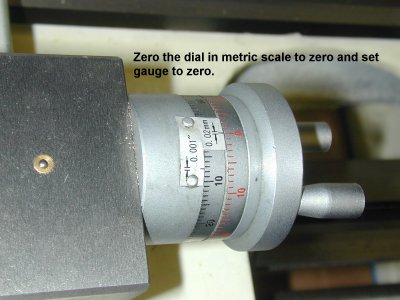

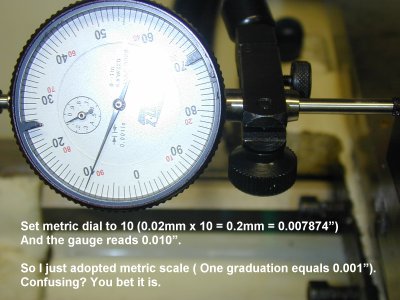

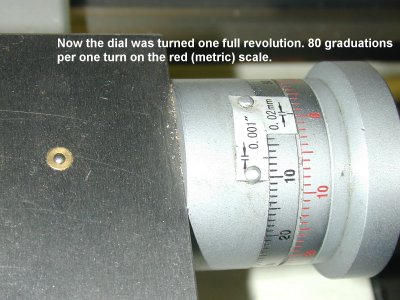

Would others please verify the accuracy of PM1236 top slide micrometer dial.</SPAN>

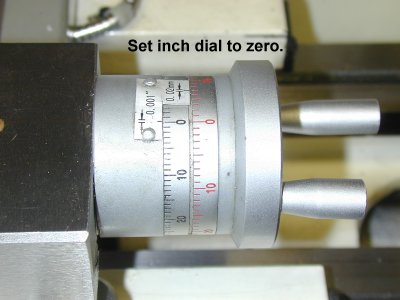

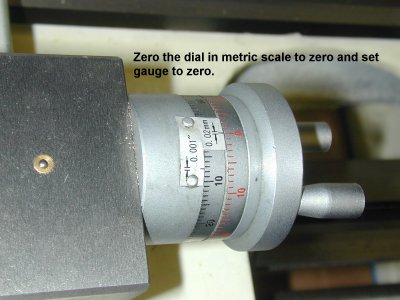

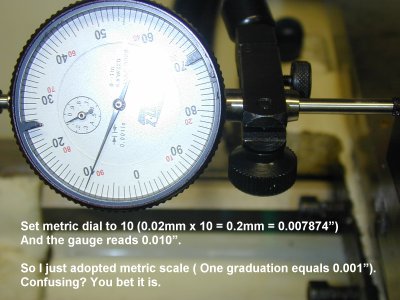

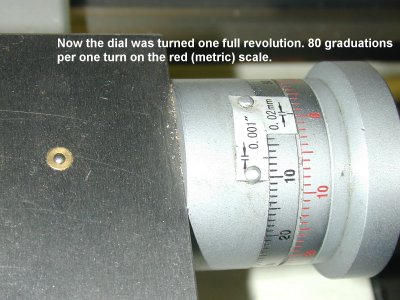

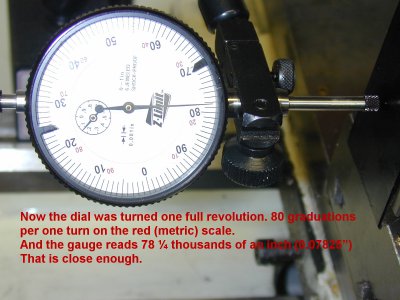

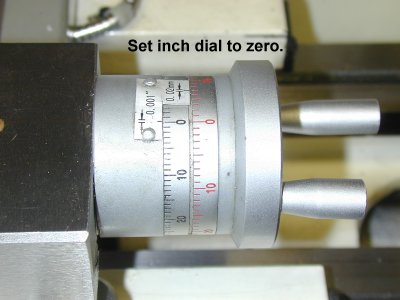

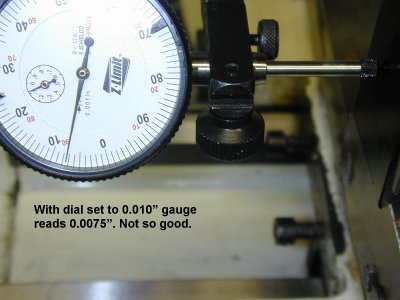

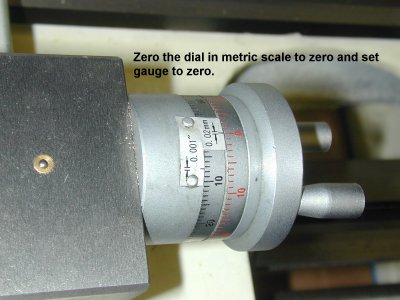

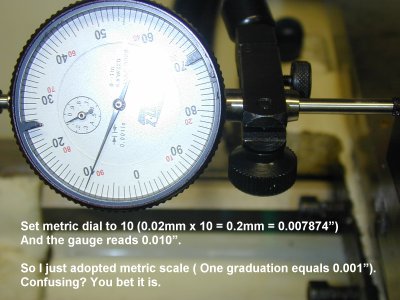

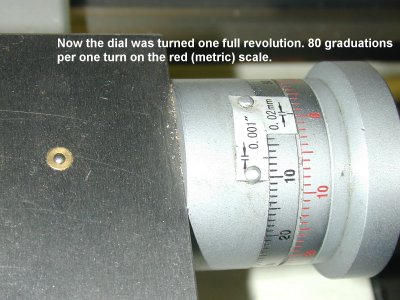

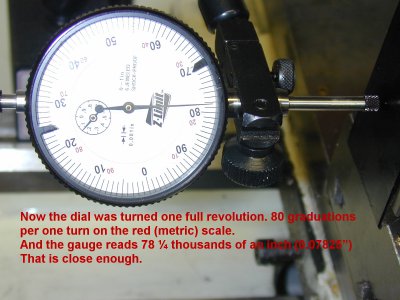

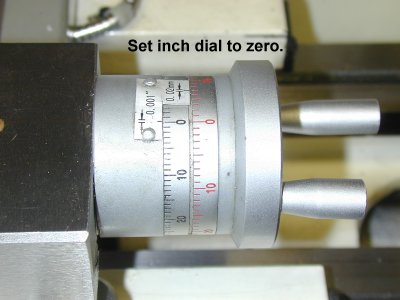

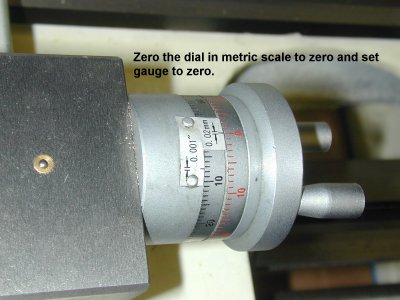

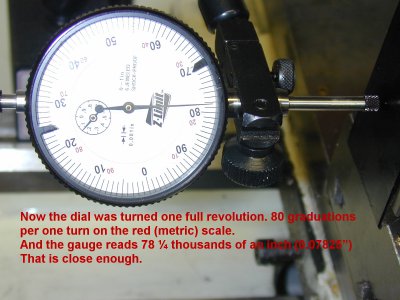

I have to use the red scale for imperial measures and black scale for metric.</SPAN>

Other words the little sticker is backwards. I was wondering why I had to keep taking more and more material.</SPAN>

For those who are unable to see pictures I posted the PDF file of all pictures on the server located here:</SPAN>

http://www3.telus.net/oceanready/compounddial.pdf</SPAN>

Cheers,</SPAN>

Radek

</SPAN>

located here:</SPAN>

http://www.hobby-machinist.com/showthread.php?t=22392</SPAN>

I am starting new thread of PM1236 lathe Compound Slide Dial.</SPAN>

Will. Thank you for your spectacular documentation of your PM1236 Lathe dials, and here are my results. I think I ordered my PM1236 right after you as I recall your postings and attempted to do a lot modifications you did. I purchased my PM1236 in March 2011.</SPAN>

Would others please verify the accuracy of PM1236 top slide micrometer dial.</SPAN>

I have to use the red scale for imperial measures and black scale for metric.</SPAN>

Other words the little sticker is backwards. I was wondering why I had to keep taking more and more material.</SPAN>

For those who are unable to see pictures I posted the PDF file of all pictures on the server located here:</SPAN>

http://www3.telus.net/oceanready/compounddial.pdf</SPAN>

Cheers,</SPAN>

Radek

</SPAN>