- Joined

- Dec 6, 2017

- Messages

- 27

Has anyone added roller bearings to the end plates for the lead screw of the PM25, or similar mills?

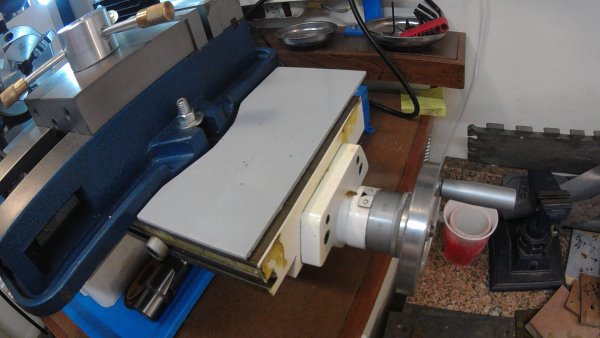

Recently added a DIY table motor drive to the left side and removed one end plate. The end plates have oil ports, which I assume are sufficient for hand cranking the table. With added speed/movement from a motor drive there might be excess wear on the lead screw, so wondering if any one has added ball bearings to reduce friction?

Don't anticipate going CNC anytime soon but would like to see if anyone bored out the end plates and what type of bearings might work best for limited home/hobby use. Thanks,

Recently added a DIY table motor drive to the left side and removed one end plate. The end plates have oil ports, which I assume are sufficient for hand cranking the table. With added speed/movement from a motor drive there might be excess wear on the lead screw, so wondering if any one has added ball bearings to reduce friction?

Don't anticipate going CNC anytime soon but would like to see if anyone bored out the end plates and what type of bearings might work best for limited home/hobby use. Thanks,