well as an update and a Christmas present to myself, i bought a china 1.8kw servo motor, cables, and drive from aliexpress for 330 bucks shipped.... it has a rated speed of 3k rpm and a reasonable power curve to the max speed of 3600 rpm. 100 and 40 tooth are surprisingly cheap there too. while big, that is the only way i can fit a 2.5:1 ratio until i figure out a way to drive it by the splines instead of that outer shaft that drives the splines.

bearings seem to be the most expensive part of this, but im not going to cheap out on that. the spindle bearings will be just almost much as that entire servo setup. still looking into options, but the SKF angular contact bearings i found are good to about 18k on grease. I dont ever see this going past 10k honestly so there is a set of tapered roller bearings that are a direct swap with no spacers for a little cheaper that are rated to 10k. i think fag or skf makes them so they are not some knock offs. i may go that route, but everyone else uses angular contacts.

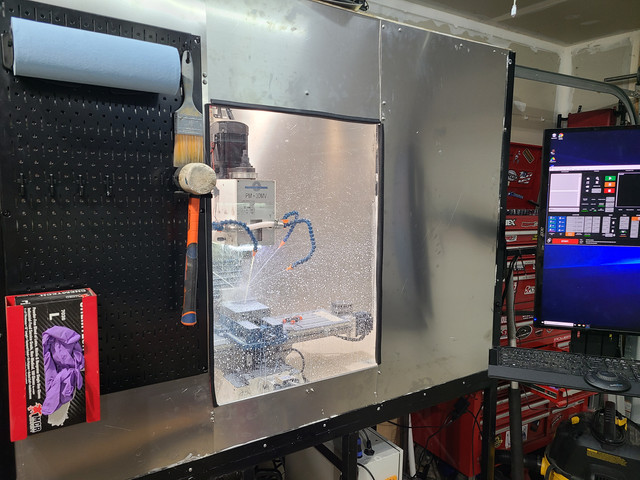

The only other thing of substance i have to add is how i routed the coolant and "filtration" system.

i am now using a dual drain setup. makes a small puddle in one spot, but maybe if i stand in it some more i can dent it enough so it drains perfectly. in each of those drains i have some steel sponges to catch the bigger chips.

from there both go into a plastic 50 cal can with scotch bright pads as a secondary filter. that pipe leading to that can is just press fit so i can remove it easy if needed. From there that is connected by a bulkhead fitting to join that to the 30mm ammo can with the submersible pump in it. from that it goes through the pump and the finer stuff is captured by a 100 micron water filter.

not the most elegant solution, but it seems to be doing a good job. when i finish the final placement of everything I'll make those hoses a proper length.

Hopefully when i get all this stuff over the next few months i can update this with a better update. And if it this thread dies here, well i failed miserably then.