- Joined

- Nov 16, 2012

- Messages

- 5,596

First, thanks for all the great cooperation on helping one another. Again, I'm sorry for being late to the game as I was hoping to blaze this trail months ago (but I cut my fingers and had to hang things up for a month or more).

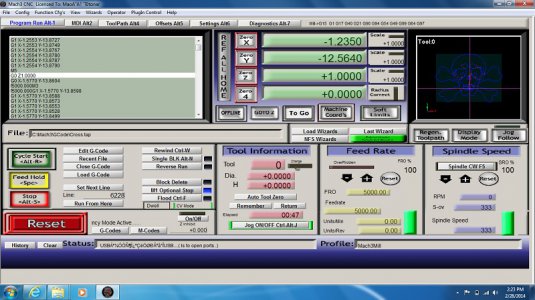

I will find time later today to revert to the older driver to see (for grins) if that makes the spindle work. If that does not pan-out, I would greatly appreciate seeing your screen shots.

As for the spindle controller. That is a 3 phase motor and it's powered with the VFD. It cannot use a digital motor controller. It must use an analog signal to control the VFD. BTW: That particular VFD is designed for good low-end torque. The thing is really expensive so don't mess it up.

FWIW: The mill is fine but, I am obviously biased. I already had a PM45 (it's 5 years old) and with the exception of limiting the gearbox to two speeds, it's the same machine. My old unit is perfect after 5 years of heavy use... Never skips a beat. I never thought to question.

I am a little baffled about the one-shot oil pump. I thought it had a timer setting and I'm trying to better understand it. Anyhow, whatever you do, DO NOT unhook one of the lines and turn it on to see if it works. -Trust me, it works. It's got a LOT of pressure. Trust me... (it shot an amazing amount of vactra #2 all over me and the shop in about 1.5 seconds). It works....

Ray

- - - Updated - - -

First, thanks for all the great cooperation on helping one another. Again, I'm sorry for being late to the game as I was hoping to blaze this trail months ago (but I cut my fingers and had to hang things up for a month or more).

I will find time later today to revert to the older driver to see (for grins) if that makes the spindle work. If that does not pan-out, I would greatly appreciate seeing your screen shots.

As for the spindle controller. That is a 3 phase motor and it's powered with the VFD. It cannot use a digital motor controller. It must use an analog signal to control the VFD. BTW: That particular VFD is designed for good low-end torque. The thing is really expensive so don't mess it up.

FWIW: The mill is fine but, I am obviously biased. I already had a PM45 (it's 5 years old) and with the exception of limiting the gearbox to two speeds, it's the same machine. My old unit is perfect after 5 years of heavy use... Never skips a beat. I never thought to question.

I am a little baffled about the one-shot oil pump. I thought it had a timer setting and I'm trying to better understand it. Anyhow, whatever you do, DO NOT unhook one of the lines and turn it on to see if it works. -Trust me, it works. It's got a LOT of pressure. Trust me... (it shot an amazing amount of vactra #2 all over me and the shop in about 1.5 seconds). It works....

Ray

I will find time later today to revert to the older driver to see (for grins) if that makes the spindle work. If that does not pan-out, I would greatly appreciate seeing your screen shots.

As for the spindle controller. That is a 3 phase motor and it's powered with the VFD. It cannot use a digital motor controller. It must use an analog signal to control the VFD. BTW: That particular VFD is designed for good low-end torque. The thing is really expensive so don't mess it up.

FWIW: The mill is fine but, I am obviously biased. I already had a PM45 (it's 5 years old) and with the exception of limiting the gearbox to two speeds, it's the same machine. My old unit is perfect after 5 years of heavy use... Never skips a beat. I never thought to question.

I am a little baffled about the one-shot oil pump. I thought it had a timer setting and I'm trying to better understand it. Anyhow, whatever you do, DO NOT unhook one of the lines and turn it on to see if it works. -Trust me, it works. It's got a LOT of pressure. Trust me... (it shot an amazing amount of vactra #2 all over me and the shop in about 1.5 seconds). It works....

Ray

- - - Updated - - -

First, thanks for all the great cooperation on helping one another. Again, I'm sorry for being late to the game as I was hoping to blaze this trail months ago (but I cut my fingers and had to hang things up for a month or more).

I will find time later today to revert to the older driver to see (for grins) if that makes the spindle work. If that does not pan-out, I would greatly appreciate seeing your screen shots.

As for the spindle controller. That is a 3 phase motor and it's powered with the VFD. It cannot use a digital motor controller. It must use an analog signal to control the VFD. BTW: That particular VFD is designed for good low-end torque. The thing is really expensive so don't mess it up.

FWIW: The mill is fine but, I am obviously biased. I already had a PM45 (it's 5 years old) and with the exception of limiting the gearbox to two speeds, it's the same machine. My old unit is perfect after 5 years of heavy use... Never skips a beat. I never thought to question.

I am a little baffled about the one-shot oil pump. I thought it had a timer setting and I'm trying to better understand it. Anyhow, whatever you do, DO NOT unhook one of the lines and turn it on to see if it works. -Trust me, it works. It's got a LOT of pressure. Trust me... (it shot an amazing amount of vactra #2 all over me and the shop in about 1.5 seconds). It works....

Ray

![20140228_140255[1].jpg 20140228_140255[1].jpg](https://www.hobby-machinist.com/data/attachments/31/31861-ad5461d94c514a0b827de81d441615b8.jpg)