- Joined

- Dec 13, 2012

- Messages

- 466

One thing I don't like about small mills is the adjustment for setting the height of the head is on the column on the back of the machine.

Very hard to reach and uncomfortable to crank. Also with my DRO on the opposite side of the machine it made it a stretching act to

read it while cranking.

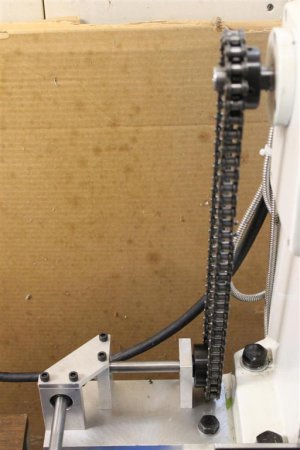

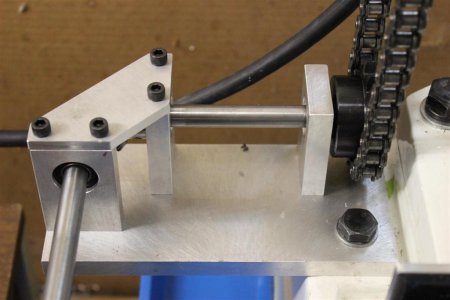

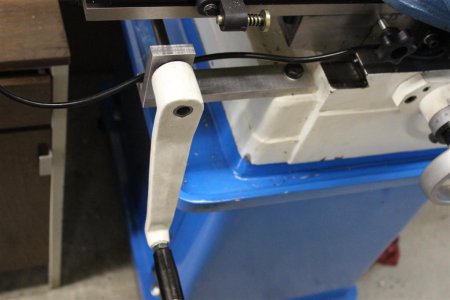

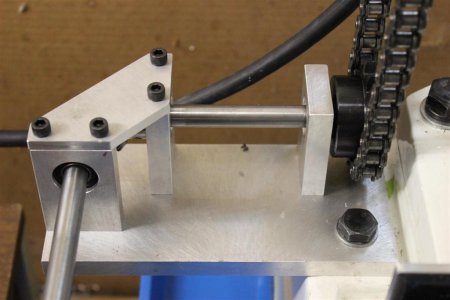

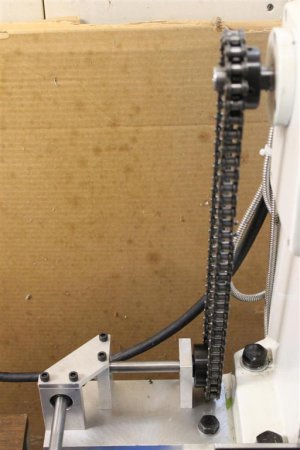

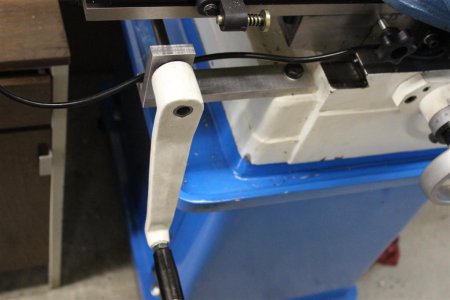

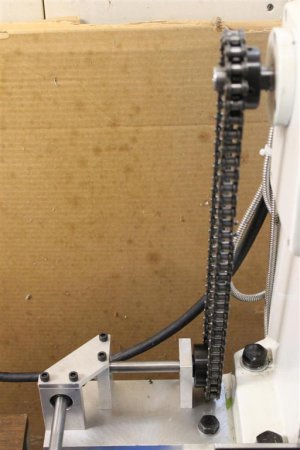

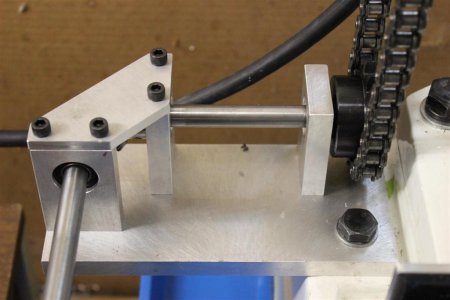

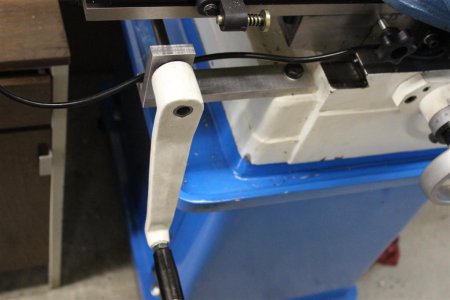

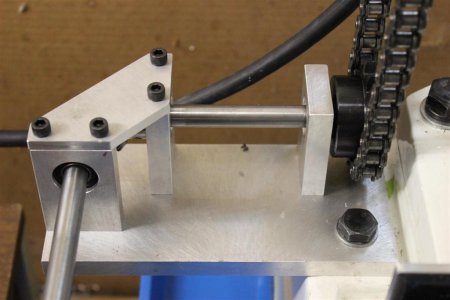

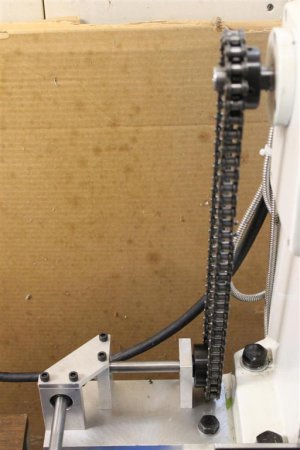

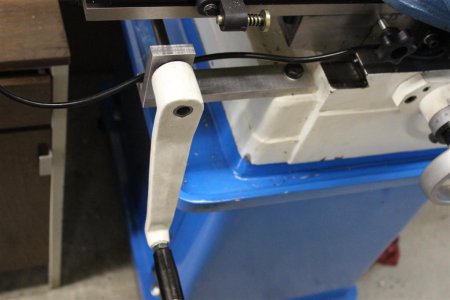

I decided a long time ago that I was going to fix that. Here is the solution that I can up with. All it takes is some roller chain, two sprockets

and two miter gears for purchased parts.

The only limitation is the table can't be too far from the column or too far to the left. The crank will hit the table if it is. This is not that big a deal

since 90% of things are done with the table near the center of the spindle. If it is necessary to move the table out of the way it's well worth it.

I am working on a couple of improvements to remove this limitation though. I am also looking at using a wheel rather than the crank. I'm just not

sure about the leverage I will get on it.

Right no the crank is fixed with the same set screw that attaches it to the column. I was thing about add a couple of slots in it and a pin through

the shaft to allow you to re-clock it and turn it around like on a knee mill.

We shall see how these work out. If you would like prints and a parts list let me know and I will create them.

One good thing is that it doesn't require any modification at all to the mill and can be put back exactly like it was.

Gary

Very hard to reach and uncomfortable to crank. Also with my DRO on the opposite side of the machine it made it a stretching act to

read it while cranking.

I decided a long time ago that I was going to fix that. Here is the solution that I can up with. All it takes is some roller chain, two sprockets

and two miter gears for purchased parts.

The only limitation is the table can't be too far from the column or too far to the left. The crank will hit the table if it is. This is not that big a deal

since 90% of things are done with the table near the center of the spindle. If it is necessary to move the table out of the way it's well worth it.

I am working on a couple of improvements to remove this limitation though. I am also looking at using a wheel rather than the crank. I'm just not

sure about the leverage I will get on it.

Right no the crank is fixed with the same set screw that attaches it to the column. I was thing about add a couple of slots in it and a pin through

the shaft to allow you to re-clock it and turn it around like on a knee mill.

We shall see how these work out. If you would like prints and a parts list let me know and I will create them.

One good thing is that it doesn't require any modification at all to the mill and can be put back exactly like it was.

Gary

Last edited: