- Joined

- Feb 4, 2014

- Messages

- 185

So, thanks to David H here on the forum, I was able to score a few Igaging Dro's for a more than fair price. Thanks David! I figured I'd post my mounting of them even though it's been done a few time already. Anywho, I got 4 in total; one 12 inch, two 24 inch, and one 36 inch. The 12 and 24 are for my mill, while the other 24 and 36 are for my lathe.

I drilled another hole in the bracket above the preexisting one for mounting the dro to the aluminum angle, mostly because I figured 4 mounting points are more rigid that 2 and I had spare room.

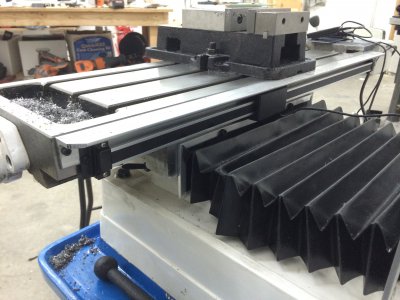

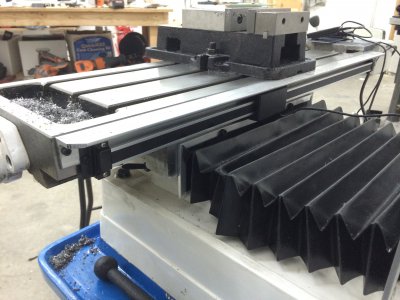

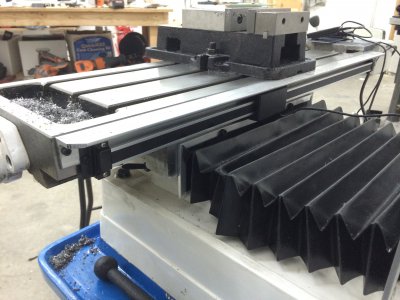

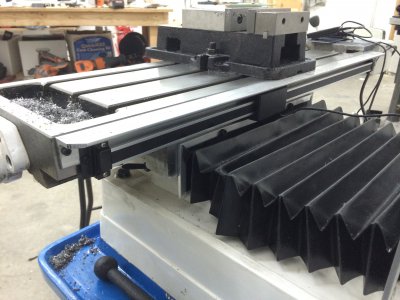

Nothing too exciting with the X-axis, This one was the easier one. I didn't get any pictures of the mounting process for that one unfortunately, but here is the aftermath. It tuned out quite nicely, I think Im going to anodize the aluminum angle Precision Mathews blue soon...might add that extra bit of class to my shop.

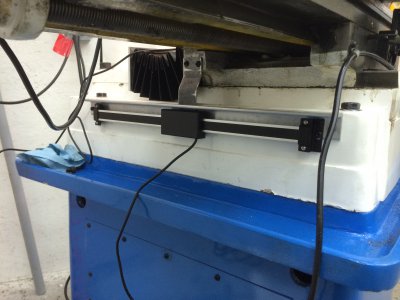

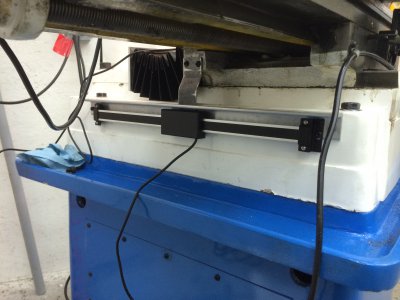

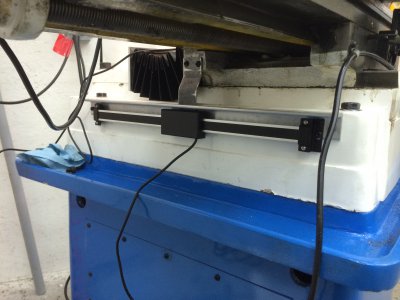

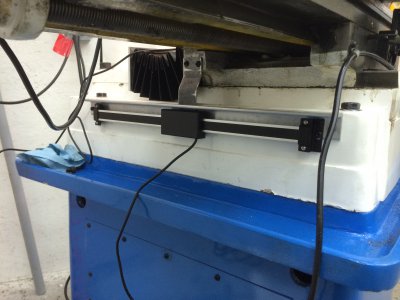

The more exciting was definitely the Y-axis. I wanted it strait up and down like the x, and also didn't want to cut or tinker with the x-axis chip guard in any way (So nice compared to my last grizzly's one). I decided to mount it down a little lower where I had easy access to a fat surface. This worried me a little because I thought I might loose some rigidity with a longer bracket, but so far I think it's plenty solid!

Regardless, I still wanted to keep the chips off my dro so I milled an 1/8" slit on top for the bracket to stick out. I managed to break my first end mill, then proceeded to toast another 2 because I accidentally left the broken tip wedged at the beginning of the cut. It was hiding under some chips and mangled the tips of both end mills before I finally realized that the loud clacking sound was not the sound aluminum makes. Ooops! Sometimes I get too excited and neglect those all-so important little details. On top of that, I also had to take out some meat on the angle to accommodate for longer screws.

I didn't realize that I needed more room for the screws until after I milled the slot, so I just used a parallel to fill the gap while I vised it up so I didn't warp the piece at all, worked great!

Ta Da!

Oddly Enough, I am having the most trouble simply figuring out where to mount my dro screens...

Anyways, I also made an extension for my Y hand wheel, got an extra inch or two of travel now so maybe I'll post that build, even as simple as it was.

Thanks all!

I drilled another hole in the bracket above the preexisting one for mounting the dro to the aluminum angle, mostly because I figured 4 mounting points are more rigid that 2 and I had spare room.

Nothing too exciting with the X-axis, This one was the easier one. I didn't get any pictures of the mounting process for that one unfortunately, but here is the aftermath. It tuned out quite nicely, I think Im going to anodize the aluminum angle Precision Mathews blue soon...might add that extra bit of class to my shop.

The more exciting was definitely the Y-axis. I wanted it strait up and down like the x, and also didn't want to cut or tinker with the x-axis chip guard in any way (So nice compared to my last grizzly's one). I decided to mount it down a little lower where I had easy access to a fat surface. This worried me a little because I thought I might loose some rigidity with a longer bracket, but so far I think it's plenty solid!

Regardless, I still wanted to keep the chips off my dro so I milled an 1/8" slit on top for the bracket to stick out. I managed to break my first end mill, then proceeded to toast another 2 because I accidentally left the broken tip wedged at the beginning of the cut. It was hiding under some chips and mangled the tips of both end mills before I finally realized that the loud clacking sound was not the sound aluminum makes. Ooops! Sometimes I get too excited and neglect those all-so important little details. On top of that, I also had to take out some meat on the angle to accommodate for longer screws.

I didn't realize that I needed more room for the screws until after I milled the slot, so I just used a parallel to fill the gap while I vised it up so I didn't warp the piece at all, worked great!

Ta Da!

Oddly Enough, I am having the most trouble simply figuring out where to mount my dro screens...

Anyways, I also made an extension for my Y hand wheel, got an extra inch or two of travel now so maybe I'll post that build, even as simple as it was.

Thanks all!

Last edited: