- Joined

- Jan 20, 2016

- Messages

- 602

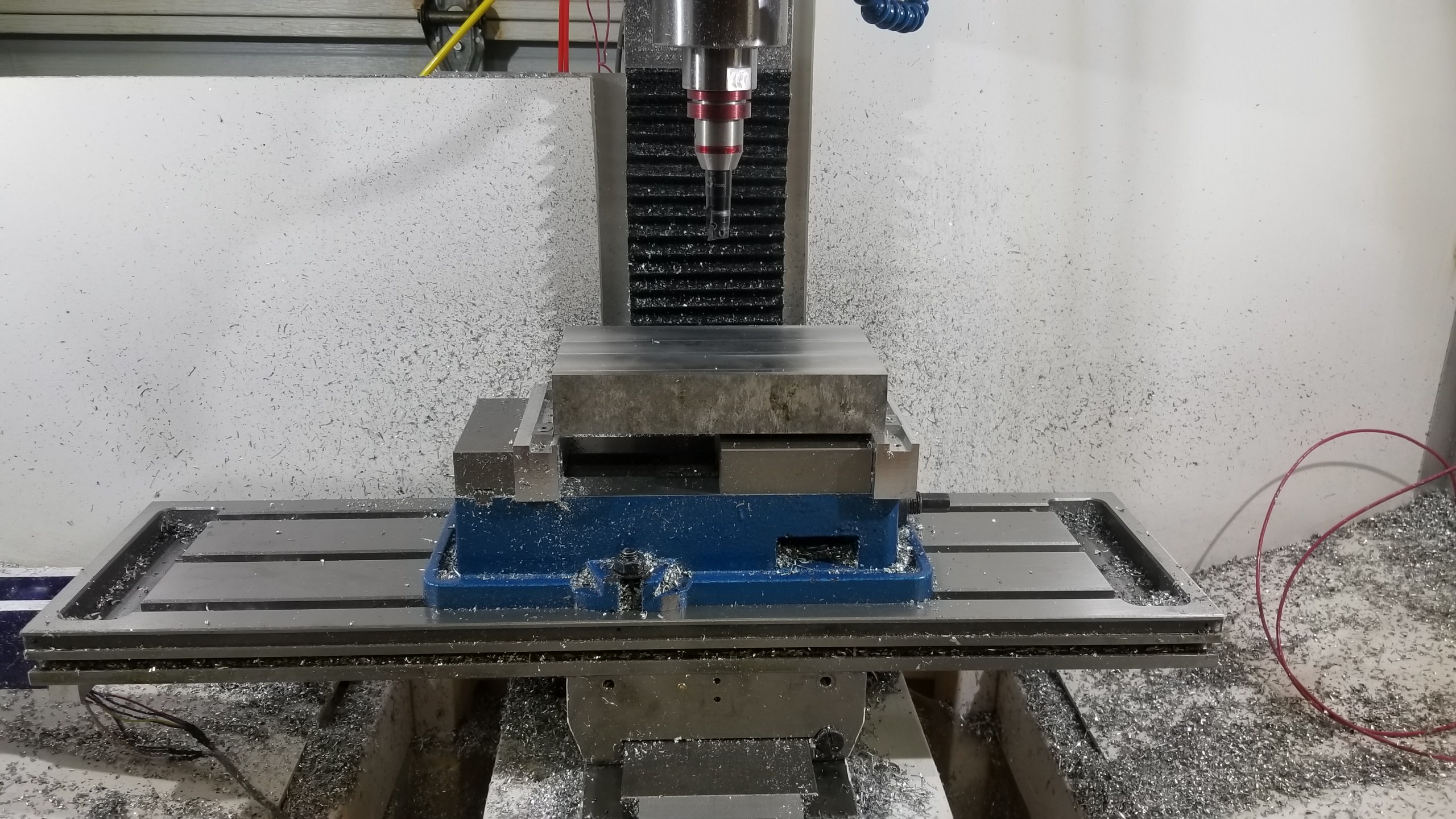

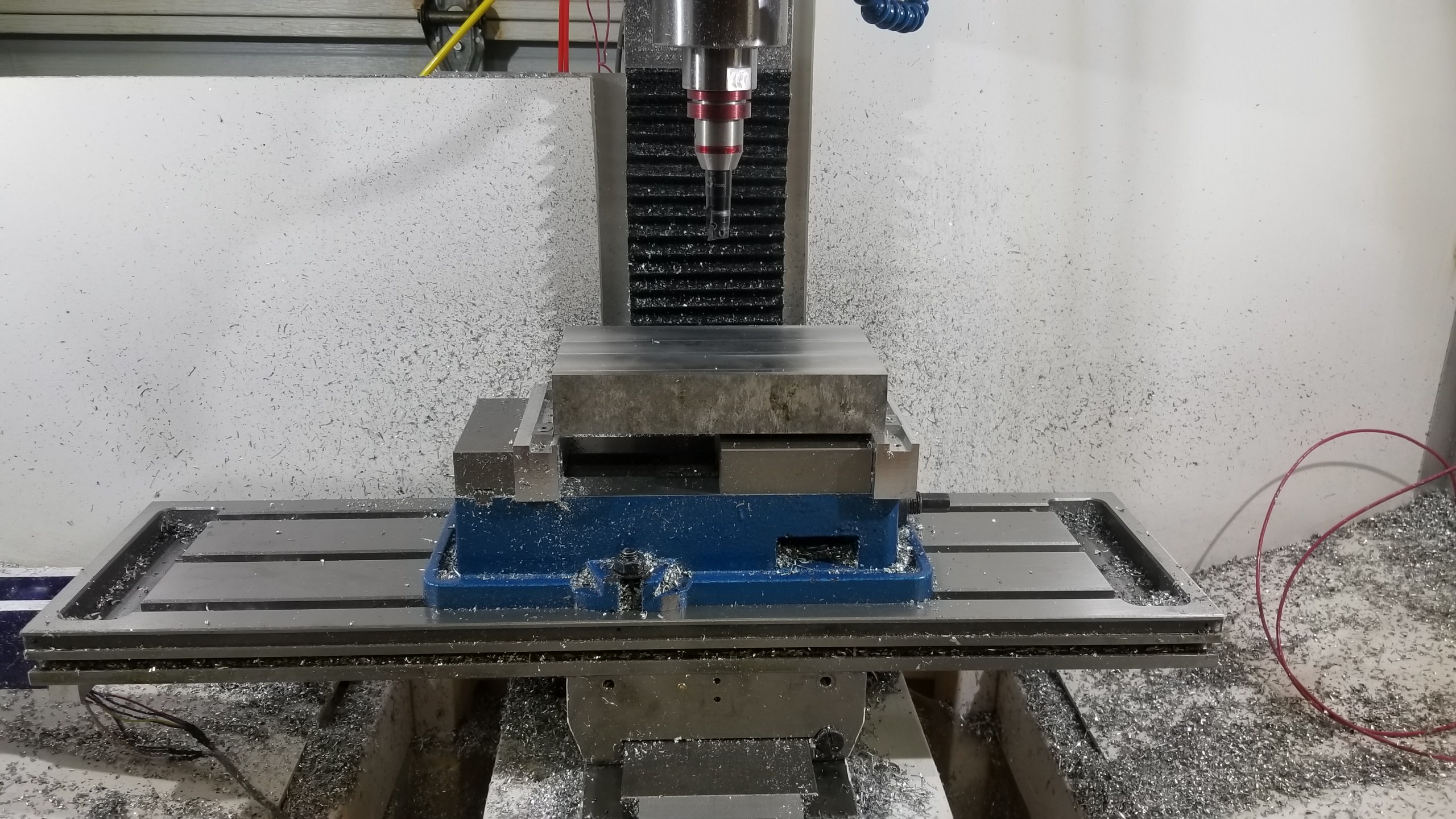

A 4" vise is about ideal for this size machine. I can fit 3 on the table pretty easily, but a 4th wouldn't be out of the question if they were all the flat sided ones.

Sideways, they fit pretty darn perfectly too. On mine, the T slots are spaced just right to bolt it down.

For standard end mills, I don't go any bigger than 3/8". I use some larger insert end mills, but those I keep the DOC shallow and increase the width a little bit. The larger end mills start getting expensive fast and I don't see the benefit for a machine as small as ours.

I have an inexpensive no name boring head and a tormach arbor for it. It works just fine, but I wouldn't bother with the arbor if you aren't planning to CNC or go with tormach tooling eventually.

Sideways, they fit pretty darn perfectly too. On mine, the T slots are spaced just right to bolt it down.

For standard end mills, I don't go any bigger than 3/8". I use some larger insert end mills, but those I keep the DOC shallow and increase the width a little bit. The larger end mills start getting expensive fast and I don't see the benefit for a machine as small as ours.

I have an inexpensive no name boring head and a tormach arbor for it. It works just fine, but I wouldn't bother with the arbor if you aren't planning to CNC or go with tormach tooling eventually.