- Joined

- May 24, 2016

- Messages

- 165

Hi Guys,

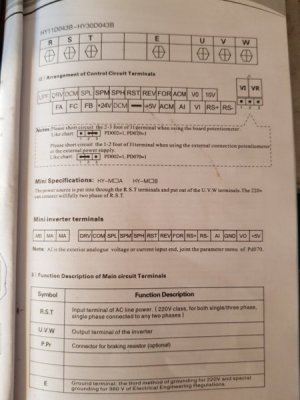

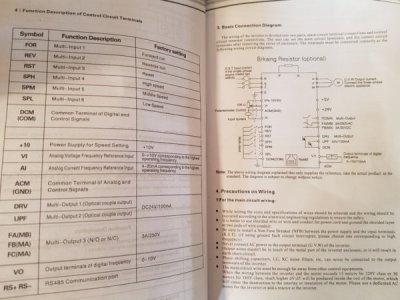

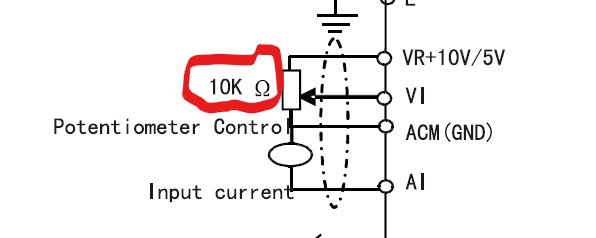

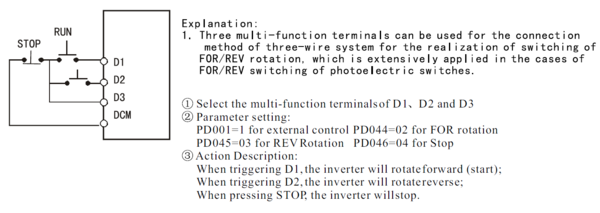

I want to wire in some on and off push buttons and speed control pot to this cheap 2hp VFD I am about to hook up to my new belt grinder. I just want the unit away from the dust and have a smaller better looking panel to control from. Can anyone please give me some advice about what rating and size etc for the pot and buttons?

I want to wire in some on and off push buttons and speed control pot to this cheap 2hp VFD I am about to hook up to my new belt grinder. I just want the unit away from the dust and have a smaller better looking panel to control from. Can anyone please give me some advice about what rating and size etc for the pot and buttons?