- Joined

- Mar 12, 2014

- Messages

- 1,531

My order from McMaster Carr arrived yesterday. I ordered some parts for another Jeep bumper that I need to build, this one for a friend, so while was ordering I also ordered a few handles for the receivers in my benches and the transmission fixture I just fabricated.

I then commenced another project that I have wanted to build for two years now, ever since I purchased my M-K Products weld positioner, an arm support for TIG welding that I can locate on my bench then adjust height and angle for support during the welding process.

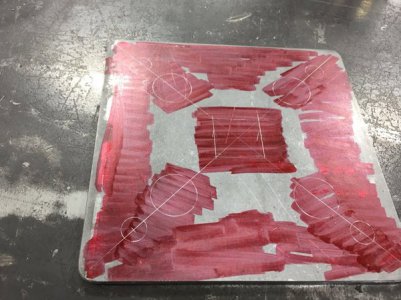

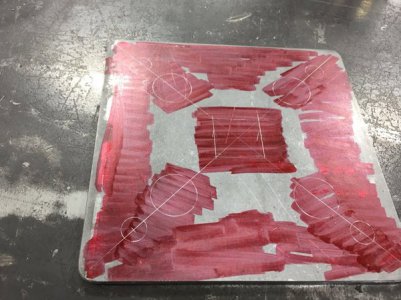

The plate scribed and ready to drill some speed holes.

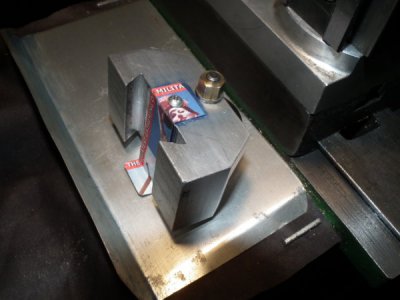

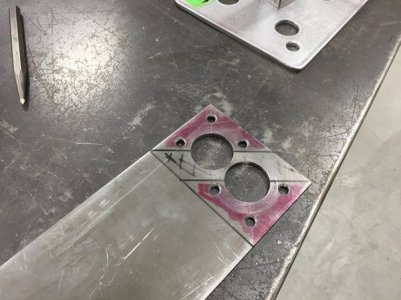

Clamped in the drill press drilling speed holes.

Gussets will also have speed holes.

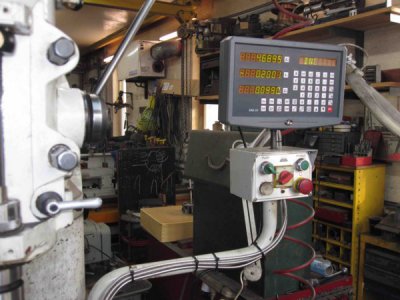

Machining three 3/8”-16 threaded bungs for locking handles.

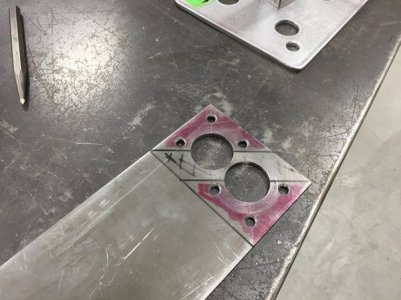

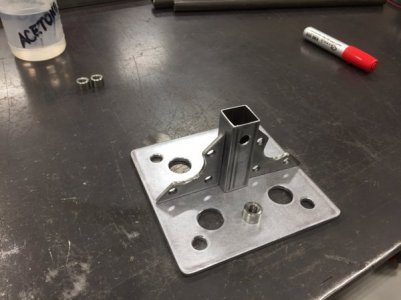

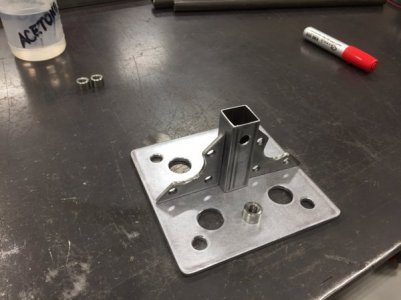

The base is ready to weld together then I can commence fabricating the movable/adjustable section.

Stay tuned..... the remaining components should reveal the what the final product will be soon.

Mike

I then commenced another project that I have wanted to build for two years now, ever since I purchased my M-K Products weld positioner, an arm support for TIG welding that I can locate on my bench then adjust height and angle for support during the welding process.

The plate scribed and ready to drill some speed holes.

Clamped in the drill press drilling speed holes.

Gussets will also have speed holes.

Machining three 3/8”-16 threaded bungs for locking handles.

The base is ready to weld together then I can commence fabricating the movable/adjustable section.

Stay tuned..... the remaining components should reveal the what the final product will be soon.

Mike