-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Sep 22, 2019

- Messages

- 938

Oversize shoulder bolt for worn deck hangers on a Cub with the monster 60" Haban deck.

Holes are hogged out, making new ones to fit the oversize holes.

Only took me the better part of a day and finally succeeded on the 3rd try!! Oh well!!

for a 3/4" wrench.

Still not perfect, you can tell by the flats! But I have 3 more to make starting with 7/8" round stock.

Holes are hogged out, making new ones to fit the oversize holes.

Only took me the better part of a day and finally succeeded on the 3rd try!! Oh well!!

for a 3/4" wrench.

Still not perfect, you can tell by the flats! But I have 3 more to make starting with 7/8" round stock.

Attachments

- Joined

- Nov 25, 2015

- Messages

- 8,235

Did you harden it? I made something similar for a reclining chair for my son. it was pop-pops before he passed. damn sawed thru. So the second one was 4140, hardened. It's been good.Oversize shoulder bolt for worn deck hangers on a Cub with the monster 60" Haban deck.

Holes are hogged out, making new ones to fit the oversize holes.

Only took me the better part of a day and finally succeeded on the 3rd try!! Oh well!!

for a 3/4" wrench.

Still not perfect, you can tell by the flats! But I have 3 more to make starting with 7/8" round stock.

- Joined

- Nov 25, 2015

- Messages

- 8,235

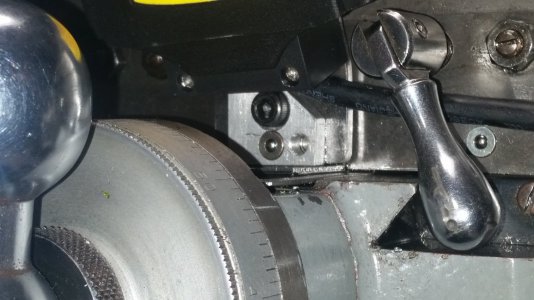

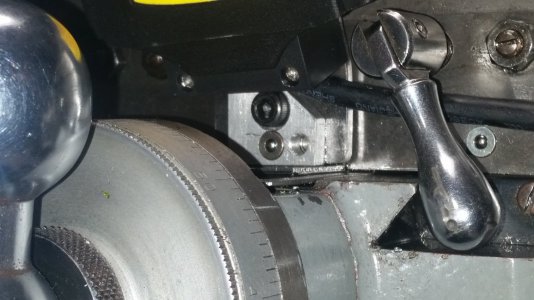

So I finished off the power feed install yesterday, the cut off switch is installed.

I had a problem that is wierd. I had to transfer a hole pattern to the bent metal bracket, and also to add a block in front to hold the screw and oiler. I was planning on putting the pins in the block but wound up not needing them.

soI was sweating that, and finally realized, make the block first, glue with C/A the original block to the new block, transfer punch them in case... and drill them thru the old block. This worked well. Then do the same to the metal bracket. This popped off during the second hole due to the heat. But no problem I have the transfer marks. I double check and everything looks lined up..

Nothing lines up. The metal bracket, the aluminum block... Everything is off by a few thou. The AL block is out even though it was drilled through the old block.. Due to the bend in the bracket, I needed the smaller AL block so I could transfer. The original block is counter sunk for the socket head cap, so only one side is valid for an accurate marking, which is why I needed the AL Block. A little hand filing fixed things up.. but quite agravating not being able to copy the holes over easily.

Original block.

New blocks and bracket.

I had a problem that is wierd. I had to transfer a hole pattern to the bent metal bracket, and also to add a block in front to hold the screw and oiler. I was planning on putting the pins in the block but wound up not needing them.

soI was sweating that, and finally realized, make the block first, glue with C/A the original block to the new block, transfer punch them in case... and drill them thru the old block. This worked well. Then do the same to the metal bracket. This popped off during the second hole due to the heat. But no problem I have the transfer marks. I double check and everything looks lined up..

Nothing lines up. The metal bracket, the aluminum block... Everything is off by a few thou. The AL block is out even though it was drilled through the old block.. Due to the bend in the bracket, I needed the smaller AL block so I could transfer. The original block is counter sunk for the socket head cap, so only one side is valid for an accurate marking, which is why I needed the AL Block. A little hand filing fixed things up.. but quite agravating not being able to copy the holes over easily.

Original block.

New blocks and bracket.

Looks like you were working it tight quarters. Turned out nice. Love it when a plan comes together..............So I finished off the power feed install yesterday, the cut off switch is installed.....

- Joined

- Sep 22, 2019

- Messages

- 938

Would if I knew how!Did you harden it? I made something similar for a reclining chair for my son. it was pop-pops before he passed. damn sawed thru. So the second one was 4140, hardened. It's been good.

Care to enlighten me??

Anyone??

- Joined

- Nov 25, 2015

- Messages

- 8,235

I didn't work on it there, just installed it there. It worked, but damn if I can figure out why it almost didn't.Looks like you were working it tight quarters. Turned out nice. Love it when a plan comes together..............

- Joined

- Nov 25, 2015

- Messages

- 8,235

I'm no expert when it comes to hardening. I heated it cherry red with a mapp torch.. let it stay there for a while. Then quenched in motor oil. Then cleaned it up so it was silvery again.. Then switched to propane and slowly brought it up to a straw color. Right or wrong, it's been surviving the sawing action... First one didn't last long at all.. I was surprised..Would if I knew how!

Care to enlighten me??

Anyone??

- Joined

- Nov 25, 2015

- Messages

- 8,235

yea, oa is fine.Oxy/acyt work just as well??

You gotta do it twice then??

well if you don't it's brittle, you have to temper it so it's not glass hard. The longer you heat soak it the better. Real heat treatment is lengthy in an oven, but this is how we do it w/out a heat treat oven.