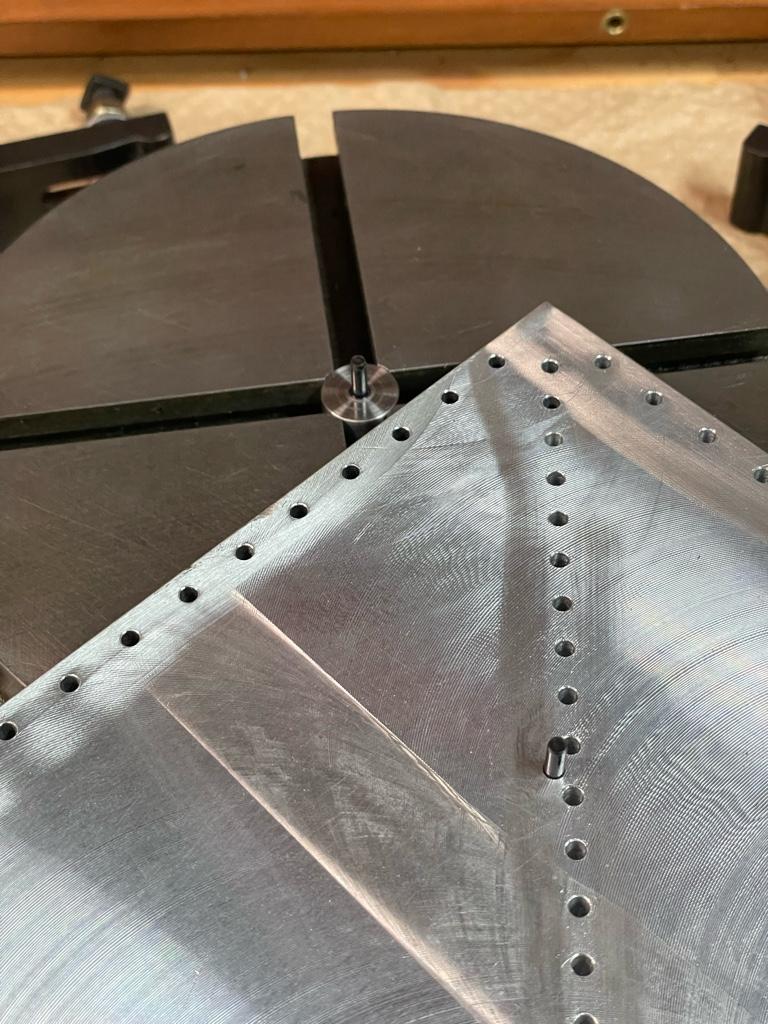

Working on the largest chunk I've ever put on a bridgeport table.

This is the gantry for a 4x8 CNC router that I'm building with some friends. The raw weldment is 60-1/2" long and somewhere around 120-130 lbs. Two 4x4x3/16" square tubes with a 2-1/2" gap between for the ballscrew. 1/4" thick end plates and 2" square tube spacers holding them together. 1" wide strips to support the linear rails are stitch welded on the front.

First step was to get it mounted on the table. We planned the design around this operation. The 2x2 spacer tubes are cross drilled 5/8" for clamping studs and the outer two are located so they line up with the bridgeport table slots. Since it is a weldment it is distorted. We're supporting it on three points so that it won't spring after we unclamp it. Dialed it in more-or-less parallel to the table since the final accuracy comes from the machining, not the original weldment.

Drilled three 0.250 reference holes in the front face of the upper tube. One dead center, the others exactly 11" each way. We have to rotate the turret and extend the ram to reach the ends, but we can put a dowel pin in a collet and pick up at least one reference hole at any turret location so we can properly set the DRO.

Pictured is milling the linear rail support strips. We did the middle section first, then rotated the turret to the left and finally to the right.

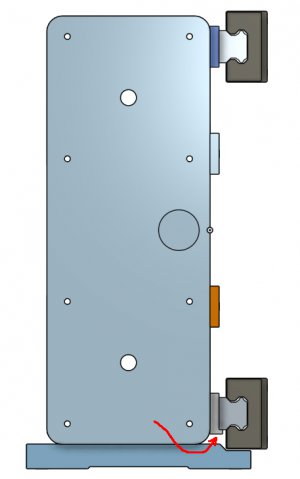

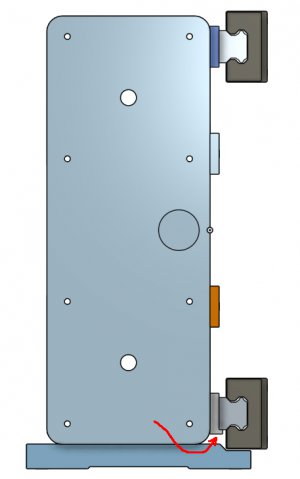

The upper strip started 1/4" thick and we milled off about 0.030 full width in the middle. Because the weldment is distorted it was closer to 0.070 at the ends, but the result is a flat front face. The lower strip started out 5/16" thick. It is milled flat to the other strip, so we took off about 0.090 in the middle and roughly 0.130 at the ends. Unlike the top strip we didn't mill all the way across, instead we left a shoulder on what will be the bottom edge. (See red arrow in the CAD screenshot.) That way when we mount the linear rail we can clamp it against the shoulder so it will be straight in that axis.

Next step will be drilling and tapping the 50 holes to mount the linear rails. Same setup on the bridgeport, again using the reference holes so we can continue the hole pattern accurately after moving the turret. We were hoping to do it all last night but the milling went slowly and it got late. We left everything set up for the drilling...