-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Nov 23, 2014

- Messages

- 2,606

Glad you're not burning cow pies!I shoveled 700 lbs of coal, 150 lbs of ash, it was +7 with a 12 mph wind, I wore Carhartt Arctic overalls and a bomber hat and I greased my face with Bag Balm. I know, no picture it never happened, boy that hot shower felt good this evening. Ok, here's a picture.

Bruce

- Joined

- Mar 17, 2018

- Messages

- 1,400

- Joined

- Sep 5, 2013

- Messages

- 3,206

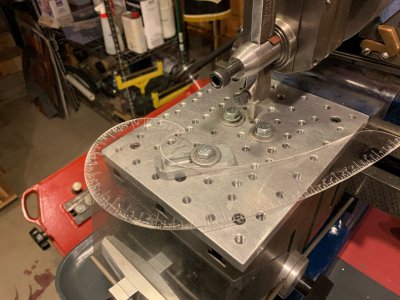

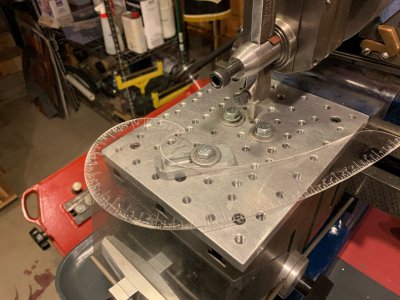

killed a bit of time in the afternoon today and made this French curve. I have a set of curves in my old drafting set but they’re small and for fooling around with garment patterns some larger sizes are more useful. And as usual, yes you can buy these, but where’s the fun in that?

I had some scrap polycarbonate on hand that I figured would be good and there are numerous places on line where you can download printable French curve templates. So I printed one off and rubber-cemented it to the Lexan. Twice. The first time of course I glued it on the usual way with the printed side out but that wasn’t going to work — I needed to see the printed side through the Lexan. Duh.

Anyway, cutting the shape was simple on the bandsaw and I cleaned up the edges with some 180 sandpaper. The graduations came next with the shaper getting the nod to accomplish that. Astute persons will know that because I’m registering the piece across two work stops the length of the hash marks will not be consistent along the full length because the curve itself is not constant along the length. But I decided I could live with that in the interest of keeping the process relatively simple. I have a nice hand wheel on the shaper which makes doing light cuts like this very easy, no need to power the motor at all.

Rubber cement peels off cleanly so all I had to do to finish up was a light polish with some Novus #2. For the numerals I just engraved them in freehand with a small dental burr in my Dremel tool.

All in all it came out okay. As I’m writing this I’m realizing I forgot to drill in a hangy-hole at the top but I think everybody probably knows what that would look like. Thanks for watching.

-frank

I had some scrap polycarbonate on hand that I figured would be good and there are numerous places on line where you can download printable French curve templates. So I printed one off and rubber-cemented it to the Lexan. Twice. The first time of course I glued it on the usual way with the printed side out but that wasn’t going to work — I needed to see the printed side through the Lexan. Duh.

Anyway, cutting the shape was simple on the bandsaw and I cleaned up the edges with some 180 sandpaper. The graduations came next with the shaper getting the nod to accomplish that. Astute persons will know that because I’m registering the piece across two work stops the length of the hash marks will not be consistent along the full length because the curve itself is not constant along the length. But I decided I could live with that in the interest of keeping the process relatively simple. I have a nice hand wheel on the shaper which makes doing light cuts like this very easy, no need to power the motor at all.

Rubber cement peels off cleanly so all I had to do to finish up was a light polish with some Novus #2. For the numerals I just engraved them in freehand with a small dental burr in my Dremel tool.

All in all it came out okay. As I’m writing this I’m realizing I forgot to drill in a hangy-hole at the top but I think everybody probably knows what that would look like. Thanks for watching.

-frank

- Joined

- May 13, 2019

- Messages

- 1,016

- Joined

- Feb 13, 2017

- Messages

- 2,138

There is a tooling size of 3/32 inch (I think) that is 0.092xx. Would that be close enough? 3/32 says to me a dentist tool most likely.I have some like that that I got many years ago from my dentist. At least the peculiarly-shaped end looks the same and is what caught my eye in your photo. When I got mine they were already a little rusty (compared to a lot of smaller ones I got from the same guy) so it made me suspect they were maybe for an old-style hand piece that wasn’t used much anymore. I still use the smaller burrs I got from him for hand engraving and micro-routing, but the larger ones I never have used — the shank is a weird size at about 0.090” so none of my Dremel collets fit.

-frank

View attachment 390670

.

- Joined

- Nov 25, 2015

- Messages

- 8,235

not dentist. I have dental burrs, I asked my dentist for some that were no longer good for him.There is a tooling size of 3/32 inch (I think) that is 0.092xx. Would that be close enough? 3/32 says to me a dentist tool most likely.

.

they work on ceramics and they go quick. He was glad to give me a few. They turn out to be way too small for me to use, even in a dremel, I can barely see them.

These are for shaping caps and veneers.

not for in the mouth.

The one to the left is the smallest I have. What goes in the mouth is smaller.

Last edited:

- Joined

- Feb 13, 2017

- Messages

- 2,138

That could turn out to be an expensive move. Lawyers tend to be a greedy lot on good days and the situation can go south in a hurry. I am no longer in business for several reasons, old age and medical not near the complete list. But the business, without any assets any more, is still viable (I think) and serves as a buffer between me and the cold, cruel world. IWell as of now im trying to not go as a business unless i get more jobs. I dont want to deal with taxes and such if i have no work. Since i opened up shop in August i only got one job granted i did not really push to find any either

If you bought something with your personal money, it is not corporate property, even if it is used for corporate purposes. With no assets now, I can tell any lawyer to go fly a kite if anything ever comes up. I doubt it ever will, but having that in the background lets me sleep better. Disclaimer: Not legal advice by any means but worth looking into. I obviously don't like lawyers, but they do serve a valid purpose. Just my misfortune to have had several bad experiences with them.

.

.

- Joined

- Feb 13, 2017

- Messages

- 2,138

The collet size is either 3/32 or 2.5mm. I specifically remember the 3/32 as a size for sale somewhere in my past. If they are not dentist tools, they are for something. I don't like collets on a Dremel because I am swapping tools so often. My Dremels (3) are fitted with small 3 jaw chucks that are available(?) from Dremel. When I bought them, anyway. . . I have fitted them to my full sized machines as well.not dentist. I have dental burrs, I asked my dentist for some that were no longer good for him.

they work on ceramics and they go quick. He was glad to give me a few. They turn out to be way too small for me to use, even in a dremel, I can barely see them.

These are for shaping caps and veneers.

not for in the mouth.

View attachment 391010

.