- Joined

- Aug 6, 2015

- Messages

- 3,884

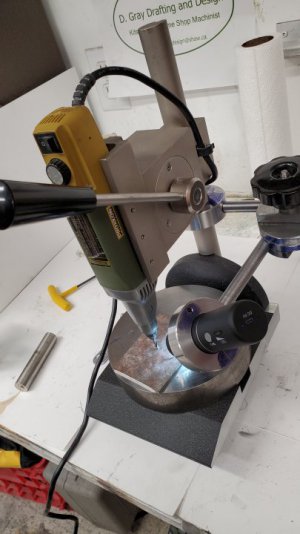

I have a smaller one... Model 40-530... I wonder if that one can be use in the same way... will check the next time I am at the other house.Just an FYI. The older Delta scroll saws model 40-440 and similar are also capable of die filing. I was interested in purchasing a commercial die filer some 15 years ago. The ones I found were either worked to death or had outrageous asking prices. I decided to see if I could modify a Delta scroll saw to do the job. I purchased one with the intention of modifying it, but much to my surprise I found they came from the factory with this capability. They could be purchased with a chuck made specifically to hold die files.

The chuck is simple to make and works well. I've used my machine a number of times as a die filer. I've yet to use it as a scroll saw. These machines seem to be fairly prolific at used equipment dealers, and usually sell for around $125.00 or so. There are a couple different models. One has 4 speeds accomplished by changing the position of the belt on the pulleys, and the other had a crank adjustable variable variable width pulley. The one I have is the 4-speed belt change model.

Here's a link to the 1940 Delta Power Tool Catalog on the Vintage Machinery website. Scroll saws and accessories begin on page 21.

Of course, now I am searching for a 40-440 and it will be super expensive because the secret is out...

But buying the ML-18 Filing Machine kit is not about getting a filing machine... it is about making one. The process of getting those castings ready... and making the necessary parts to put it together... That is where the fun is for me... I look a the photos of folks that have finished one and I want to try to do the same... I find it a thing of mechanical beauty...

Last edited:

My favorites look the same , well broken in .

My favorites look the same , well broken in .  If the sun would stay out for more than 15 minutes at a time today , I'd put mine on and start the chainsaw up . I have 3 loads of logs in the back yard to take care of .

If the sun would stay out for more than 15 minutes at a time today , I'd put mine on and start the chainsaw up . I have 3 loads of logs in the back yard to take care of .