The first rule of Fix A Starter Club, is we don't talk about Fix A Starter Club...

So, I really like Honda small engines, generators, fourwheelers, etc. All the stuff seems to be bullet proof, save for a few small things here and there.

This one issue however, I group in the bone-headed category. The starters are built with ceramic magnets glued onto a steel housing. OK, no problem there. However that glued housing is right next to the unshielded exhaust pipe! On top of that, the magnets aren't set into pockets or anything! Just glued to the surface. Once the pipe heats up, glue softens and the magnets can pop off. Then the starter jams...

After replacing a couple, I finally studied it closely enough to figure out what was going on. So, decided to add heat shelding, and extra epoxy between the magnets.

This particular unit I repaired by removing good magnets from another bad starter (with a torch!), and glued them in place. Hadn't added the extra glue then. So this weekend was a preemptive project to address that issue.

Disassembly and cleaning showed at least one magnet was cracking.

Then taped up a dam to let epoxy flow, and flooded the grooves with epoxy.

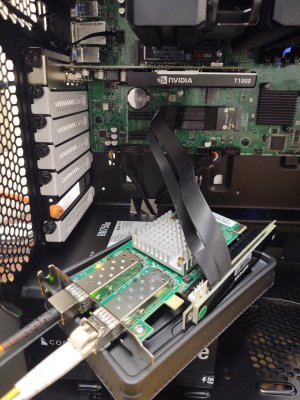

Then it was off to the garage to fabricate a heat shield for the starter side of the exhaust pipe. This is hard to image. But under that shield, an inch or so away from is the starter is the bare pipe.

Pulled the tape and extra epoxy, then using a small Dremel drum on the Foredom sanded the epoxy between the magnets just below flush.

Then bolt it all back together, and see if it starts. (It did)

Lastly, went out to check on the bumper peach crop this year. I touched it, and it fell of into my hand. So split the whole crop with the wife. I tried neem oil on the fruit this year, and the peach seemed to pick up a bitter taste. Don't think I'll be trying that again.

vvividshop.com

vvividshop.com