- Joined

- Sep 28, 2013

- Messages

- 4,306

that is one cool little vise - where'd it come from?

I have the same question. That is a cool looking vise for sure.that is one cool little vise - where'd it come from?

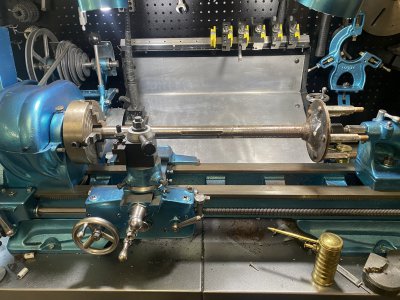

Back to working on the bushing this evening.

Close to the max for the Sherline

View attachment 461161

Managed to keep everything within specs this time.

Trim to length is going to need about .187 removed

View attachment 461151

RF 30 gets in on the action. My lack of lathe operating time is only exceeded by my lack of mill time. So rough cut to close enough and back to the lathe to finish

View attachment 461158

View attachment 461159

Need to face off .003 then call it done

View attachment 461160

that is one cool little vise - where'd it come from?

It's one of theseI have the same question. That is a cool looking vise for sure.

They sell a "superseded" one. Supposed to be a direct replacement.Is an OEM replacement available for the bearing housing or will you have to machine a new one? Looks like aluminum?

It's one of these

https://www.grizzly.com/products/grizzly-precision-self-centering-vise/h7576

If I remember correctly did a black Friday buy so I think it cost me $175.

Bought it out of fear of buggering up my costly 5" vise while I go through the milling learning curve.

Disassembled, cleaned up a few burrs, adjusted the gibbs. Fit/finish is good and it's very smooth cranking.

Self centering vises don't seem to have much of a following but it's worked out and I don't have to horse around a 50 plus pound fixed jaw.