- Joined

- Apr 23, 2018

- Messages

- 6,520

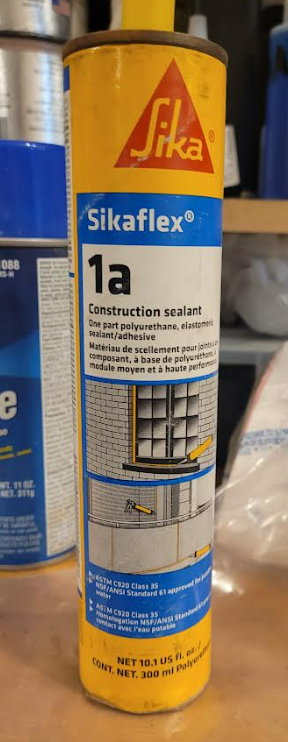

Thinking urethane windshield adhesive? Any thoughts. Would seam sealer for automotive work be impervious to cutting oil?

Greg,

Many of the soft urethanes tend to absorb oil. You would be fine with a garden-variety siloxane (silicone) caulking.

Edit: Light oils are absorbed by urethanes, heavy oil and grease is ok. Fuel oils eat it for dinner, as do any oxygenated chems like acetone (all ketones) and diols (glycols). Water based coolant is full of diols.

Last edited: