- Joined

- Oct 7, 2020

- Messages

- 2,109

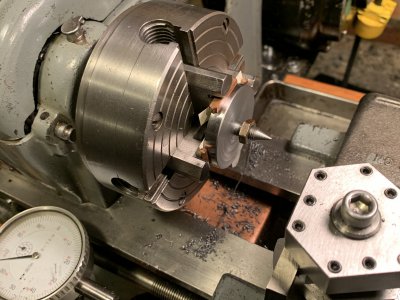

I made this little adapter/ hose connection thing. It is designed to screw into a water meter base on the large end and connect a garden hose to the other.

The reason is I'm on a community water system and the state is requiring us to install water meters, the first one we put in is at the end of the line at the very top of the hill. The property is vacant, and we never thought to install a frost free or spigot of some sort to bleed the line. Hense my little tool, I will be able to remove the meter install my tool, run a garden hose out away from the meter box and bleed/flush the system.

The threads are .75-11.5NHR (Hose Thread) on the small side and 1-11.5NPSH (Water Meter Thread) on the other. What I found out and I'm not sure why is I had to cut the threads like cutting metric threads, with the half nut engaged. The label next to the half nut on the lathe says to engage at 4,8. Even though there are no provisions/options to cut 11.5 threads on this lathe PM1236T. With the help of Dave @B2 and his spread sheet he recommended a gear combination that is very close and close enough for this application.

After ruining the first thread by engaging at 4 and then at 8, I tried just engaging at 8 but no luck, it still didn't engage at the right spot. I then just engaged at 8 and left it engaged until I was done.

The reason is I'm on a community water system and the state is requiring us to install water meters, the first one we put in is at the end of the line at the very top of the hill. The property is vacant, and we never thought to install a frost free or spigot of some sort to bleed the line. Hense my little tool, I will be able to remove the meter install my tool, run a garden hose out away from the meter box and bleed/flush the system.

The threads are .75-11.5NHR (Hose Thread) on the small side and 1-11.5NPSH (Water Meter Thread) on the other. What I found out and I'm not sure why is I had to cut the threads like cutting metric threads, with the half nut engaged. The label next to the half nut on the lathe says to engage at 4,8. Even though there are no provisions/options to cut 11.5 threads on this lathe PM1236T. With the help of Dave @B2 and his spread sheet he recommended a gear combination that is very close and close enough for this application.

After ruining the first thread by engaging at 4 and then at 8, I tried just engaging at 8 but no luck, it still didn't engage at the right spot. I then just engaged at 8 and left it engaged until I was done.