- Joined

- Mar 25, 2013

- Messages

- 4,613

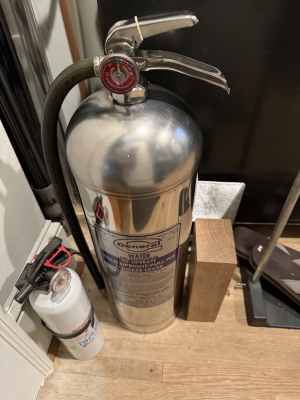

I finally got around to replacing the gauge on my fire extinguisher from 1973. In the process I broke the siphon tube which was 50 year old plastic so it probably needed to be replaced anyway. I filled up with 2.5 gal of water and recharged to 100 PSI.

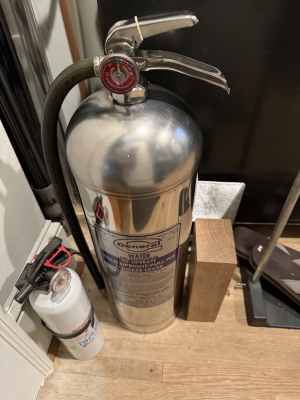

It's good practice and kind of fun to empty these outside!

It's good practice and kind of fun to empty these outside!