-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Jan 4, 2021

- Messages

- 1,771

Like most of us, gets more top heavy (or unstable - doplic as they say around here) with age!World's fanciest work light base. Got tired of the thing falling over due to the heatsink in the head

View attachment 471439

- Joined

- Jul 29, 2014

- Messages

- 2,725

Today I made a small forest of goofy little trees, two aluminum and two 12L14. The star means they're Christmas trees. I see others knurl the trees, which is a nice touch, but I was too lazy and also thought with the taper I'd probably ruin them in the process. The star was made from a half inch diameter brass round held in a spin indexer, so I could get the outline and then part off a bunch of 'em. The cuts are axial, then I drilled a small mounting hole at 36 degrees spaced appropriately, then parted off to designed thickness. There is a small nub on the apex of the tree that fits the mounting hole in the star, held with epoxy.

- Joined

- Dec 6, 2015

- Messages

- 807

I would definitely like to see a write up. Making HO scale stuff is of interest to me (I collect N, but my brother is all HO, and I've never thought of making my own posts, really).Something on the small side...

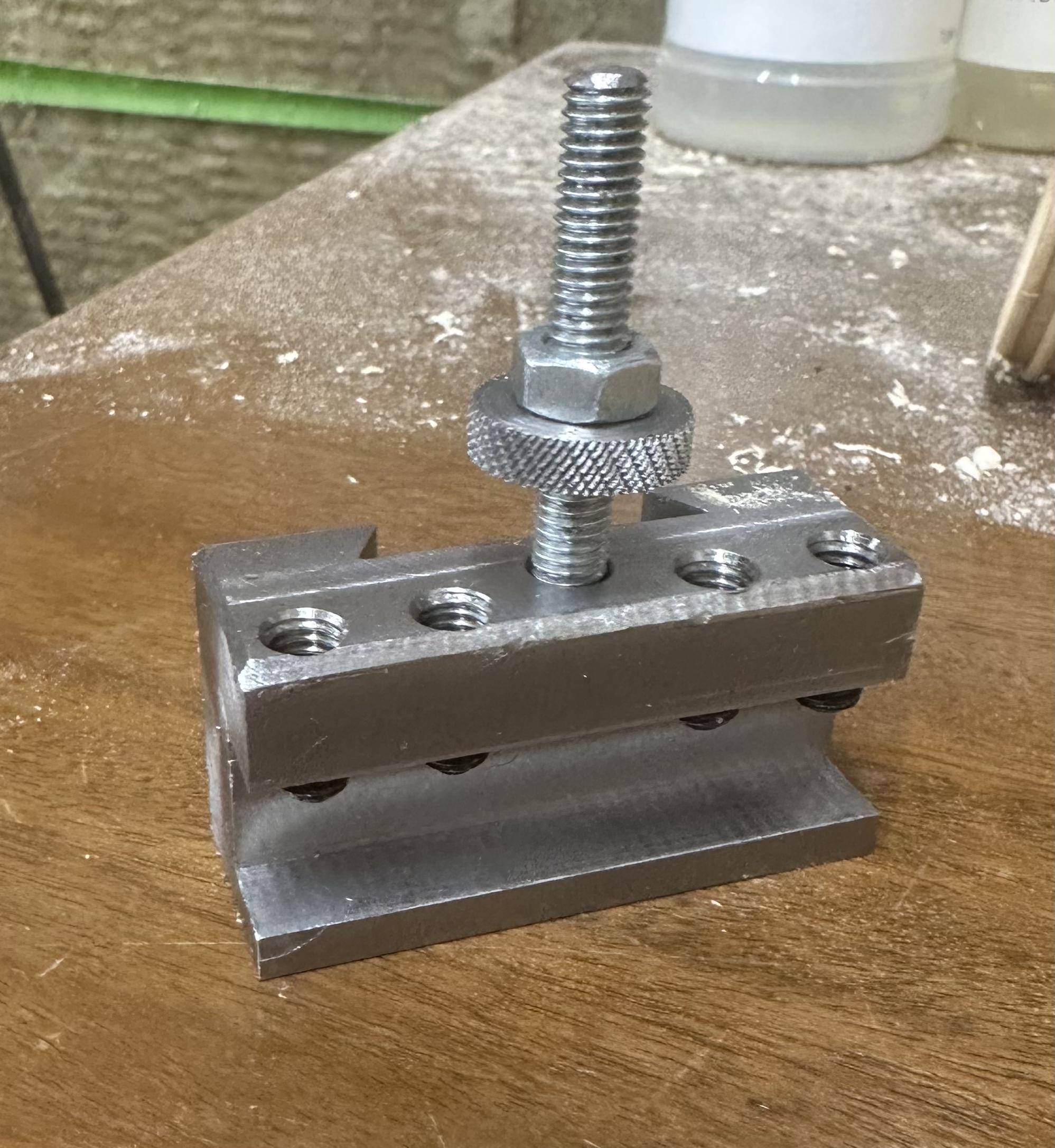

Learning this stuff as I go, first project is cutting teeny valve gear parts for my HO scale locomotive from 0.02" brass sheet. The siderods have crankpin bearings that make nice radii along the rod, so I'm working with the rotary table. Did some experimentation with various workholding, came up with this:

View attachment 471396

The workpiece is a 2x2" sandwich of 1/4" aluminum and the 0.02" brass glued together. I need to be able to slide the work up and down the X axis to center each crankpin for cutting the radii, so I made a self-squaring fence (has a small key cut in the bottom to fit the t-slot) and a clamp cut specifically to fit the sandwich. Not shown are the 0-80 screws I install in each of the drilled crankpin bearing holes to further stabilize the part as I cut it from the sheet. Haven't actually cut anything with the setup yet, but I have high hopes...

Sent from my SM-G970U using Tapatalk

- Joined

- Nov 3, 2023

- Messages

- 36

I've been keeping track of what I do here:I would definitely like to see a write up.

https://glenn.pulpitrock.net/blog/

It's all 3D printing to date, but I'll do a post on my valve gear milling endeavor when I get a successful part, in a week or so...

Edit: I may make a thread here, if it's of interest. I'm a neophyte at this, so all I say should be taken with a grain of salt.

- Joined

- Dec 6, 2015

- Messages

- 807

Bookmarked!I've been keeping track of what I do here:

https://glenn.pulpitrock.net/blog/

It's all 3D printing to date, but I'll do a post on my valve gear milling endeavor when I get a successful part, in a week or so...

Edit: I may make a thread here, if it's of interest. I'm a neophyte at this, so all I say should be taken with a grain of salt.

Sent from my SM-G970U using Tapatalk

- Joined

- Nov 24, 2014

- Messages

- 3,152

Like most of us, gets more top heavy (or unstable - doplic as they say around here) with age!

LOL From my childhood, burned into my memory is my Mother admonishing me to "Stop touching the walls!" (bold indicating high volume). She was very "house proud".

I've never been very graceful and at 3/4 of a century old, I use the walls quite often. When I do, I recall and chuckle at her admonishment. He who laughs last . . .

- Joined

- Nov 24, 2014

- Messages

- 3,152

@Winegrower

Nice work there.

Knurling a cone requires a knurl of the complimentary angle (cone shaped roller).

Although they are available to buy, I don't think I've ever seen such a conical knurl (tool) in the real world.

Not a vey common tool, IMO. Even an eBay search for "conical knurl" didn't find one.

You're judgement to not knurl was

Nice work there.

Knurling a cone requires a knurl of the complimentary angle (cone shaped roller).

Although they are available to buy, I don't think I've ever seen such a conical knurl (tool) in the real world.

Not a vey common tool, IMO. Even an eBay search for "conical knurl" didn't find one.

You're judgement to not knurl was