- Joined

- Dec 18, 2022

- Messages

- 1,640

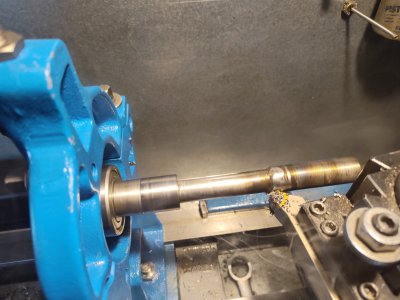

I find the Blue belts work better for metal....Cleaned up the edges on some A36 discs (they'll show up on my Shop thread once I have time to finish editing the video):

View attachment 487511

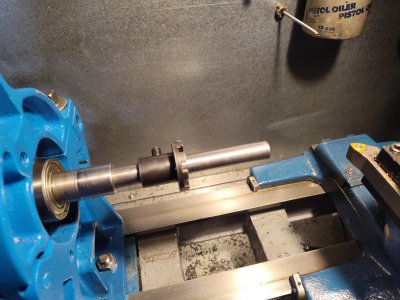

Either the Craftsman belts on my 2x42 belt sander/grinder are crap, or I've been overworking them:

View attachment 487512

I'm only getting an average of 15 years out of them – counting the original that came with the machine, this is the third one!