-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

Yea. Its an older chuck that doesn't look like its hardly ever been used. Beautiful condition of the scroll and jaws. I don't really need it. But every now and then I do want to make something precision. I could always just use a regular 4-jaw chuck. Anyway, It's another toy. We gotta have our toys.

- Joined

- Jul 29, 2014

- Messages

- 2,728

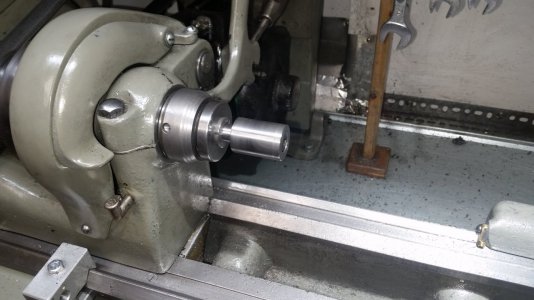

That ought to help with the old handicap.Made a new elevating screw for my golf ball mortar,

- Joined

- Aug 6, 2015

- Messages

- 3,884

Brother-in-law recommended a record brush... arrived today. Turns out it is too low for my turntable. The 1/4" adjustment is not enough to make it work.

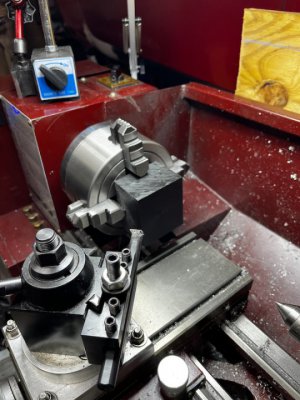

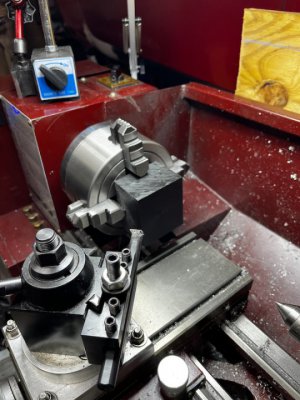

So I figured that I would make a base for it to raise it. Testing here the height needed for the spacer...

Yeah, that should do it... but now I need to make it look better... I do not have cylinder bars of Delrin... but since the lathe is to make square things round... let's do this!

And yeah, I changed the cutter for another one... I used the boring bar on a second step...

There you are...

Boring bar was used to carve out the center so the base of the brush would sit inside securely...

I then took this to the bandsaw and proceeded to cut it short of the cylinder. Placed it back in the lathe and machined the left over rectangle in the bottom... also made a recess... well, because I see other folks doing that, lol...

Man, I am new to all this... but I am so frigging proud of how this came out!!

Poifect!!

So I figured that I would make a base for it to raise it. Testing here the height needed for the spacer...

Yeah, that should do it... but now I need to make it look better... I do not have cylinder bars of Delrin... but since the lathe is to make square things round... let's do this!

And yeah, I changed the cutter for another one... I used the boring bar on a second step...

There you are...

Boring bar was used to carve out the center so the base of the brush would sit inside securely...

I then took this to the bandsaw and proceeded to cut it short of the cylinder. Placed it back in the lathe and machined the left over rectangle in the bottom... also made a recess... well, because I see other folks doing that, lol...

Man, I am new to all this... but I am so frigging proud of how this came out!!

Poifect!!

Last edited:

- Joined

- Nov 25, 2015

- Messages

- 8,284

I used to wipe my albums before playing them, not during. I would think the brushing while running would lead to noise.. a WOW effect, and shhhhhhhhhh sound.

- Joined

- Nov 25, 2015

- Messages

- 8,284

- Joined

- Aug 6, 2015

- Messages

- 3,884

I used to wipe my albums before playing them, not during. I would think the brushing while running would lead to noise.. a WOW effect, and shhhhhhhhhh sound.

I wash them with this...

And then use a brush before playing them... but sometimes there is stuff in the air that lands on the record while playing...

You know how it is... there is really no need for a lot of stuff that we buy....

- Joined

- Aug 6, 2015

- Messages

- 3,884

- Joined

- Nov 25, 2015

- Messages

- 8,284

how's that Macallan in the background? Smoooooooth?I wash them with this...

View attachment 404873

And then use a brush before playing them... but sometimes there is stuff in the air that lands on the record while playing...

You know how it is... there is really no need for a lot of stuff that we buy....

- Joined

- Aug 6, 2015

- Messages

- 3,884

Was…was…how's that Macallan in the background? Smoooooooth?

Vinyl record cleaner is concentrated, so that empty bottle was perfect for holding the diluted fluid…