Quick POTD so I could get on with the winter/spring POTD. . . I cut around 8 full cords of firewood a year to supplement our propane and geothermal furnaces. Was cutting some deadfall and my Stihl Farm Boss saw froze up. The engine ran but the chain was frozen. Pulled the bar/chain and the drive sprocket wouldn’t turn.

Turned out the blade chain brake was stuck on. The saw has a band clamp/brake that runs around the drive sprocket cup. The safety handle up top flips a trigger (over-center linkage) when pulled back. Bump it forward and the brake band is pulled tightly around the sprocket cup stopping the chain.

Pulled the trigger tensioning spring and discovered the safety handle had worn significantly where it bears against the triggering link. It was worn enough that it couldn’t push the trigger back over-center and disengage the brake.

Chain brake in the engaged position. Cryptic description, but the steel link coming out of the black handle swings down when engaged which allows the pivoting linkage (one with the "C" at the top - extension spring removed for ease of cycling the mechanism). The spring pulling to the left at the top pivots the bottom end to the right which pulls the brake band tight around the sprocket cup

View attachment 405226

Brake in the non-engaged position. Pulling the safety handle back pushes up on the link taking it over-center from a pivot locking it in place.

View attachment 405228

Brake in the non-engaged position. The bottom of the slot in the black safety handle (green arrow) should push the linkage up (2nd green arrow) to set the brake trigger. Problem was the handle had worn over the last 30 years so it would no longer push the link to the non-engaged position.

View attachment 405231

Fix was to drill an 1/8” hole and stick a dowel pin in the handle. Back to cutting wood. . . And "yes", I have thought about the reverse failure mode. What happens if the top side of the slot in the safety handle wears to the point it doesn't engage the brake? That might be a place for a 2nd dowel pin, but for now I ALWAYS verify the chain brake works after starting the saw.

Painted the handle with yellow paint and marked the position of the trigger in the engaged and non-engaged positions

View attachment 405232

Drilled an 1/8" hole through the handle and pressed in a dowel pin.

View attachment 405233

The dowel pin ate up the gap/wear in the handle. Now the trigger is steel on steel; should work forever as the plastic on steel (Stihl ?!?) worked fine for 30 years.

View attachment 405234

As an aside, there are mixed feeling about Amazon but I’m a fan. Went on line Saturday and ordered a new safety handle (off-brand) at about 5:00 PM for a whopping $12 (Stihl NOS is $50). It was delivered Sunday before 6:00 PM. I’m leaving my fixed safety handle in place, now I have a spare. And “yes”, the slot in the new part is significantly smaller than my worn one. I’ve had the saw for around 30 years, my pin fix will likely outlive me.

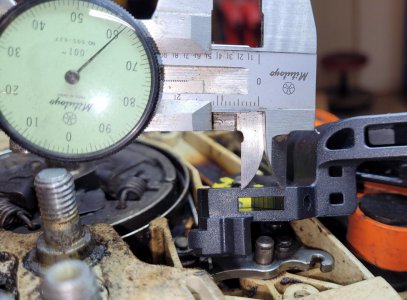

Worn safety handle opening was roughly 0.55", new part is 0.46"

View attachment 405235View attachment 405236

Thanks for looking,

Bruce