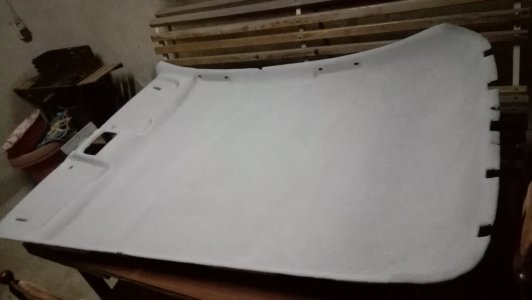

Today i had a full day of work, first at work then in the garage and last in my yard. First to get my attention was the Scenic with the new clutch now i can use the engine power but at idle the engine sounds like a bag of bolts. So i adjusted the valves, clean and re gaped the spark plugs. Not too hard but very dirty. Then i got to removing the headliner from the white elephant No 1. It's been sagging and was hold up by push pins. The old material peel off very easy and went straight in the bin. Then i used rags to peel back the old yellow backing and prepared the surface for the new material. I used Neostik glue with a brash and glued it in place. I left it to cure overnight tomorrow is going in the car. The difference is very noticable, this car always was let down by the headliner.

View attachment 407318View attachment 407324