For some reason, I really hate aluminum. I think it's the mess, and the possibility of galling up on a cutter...

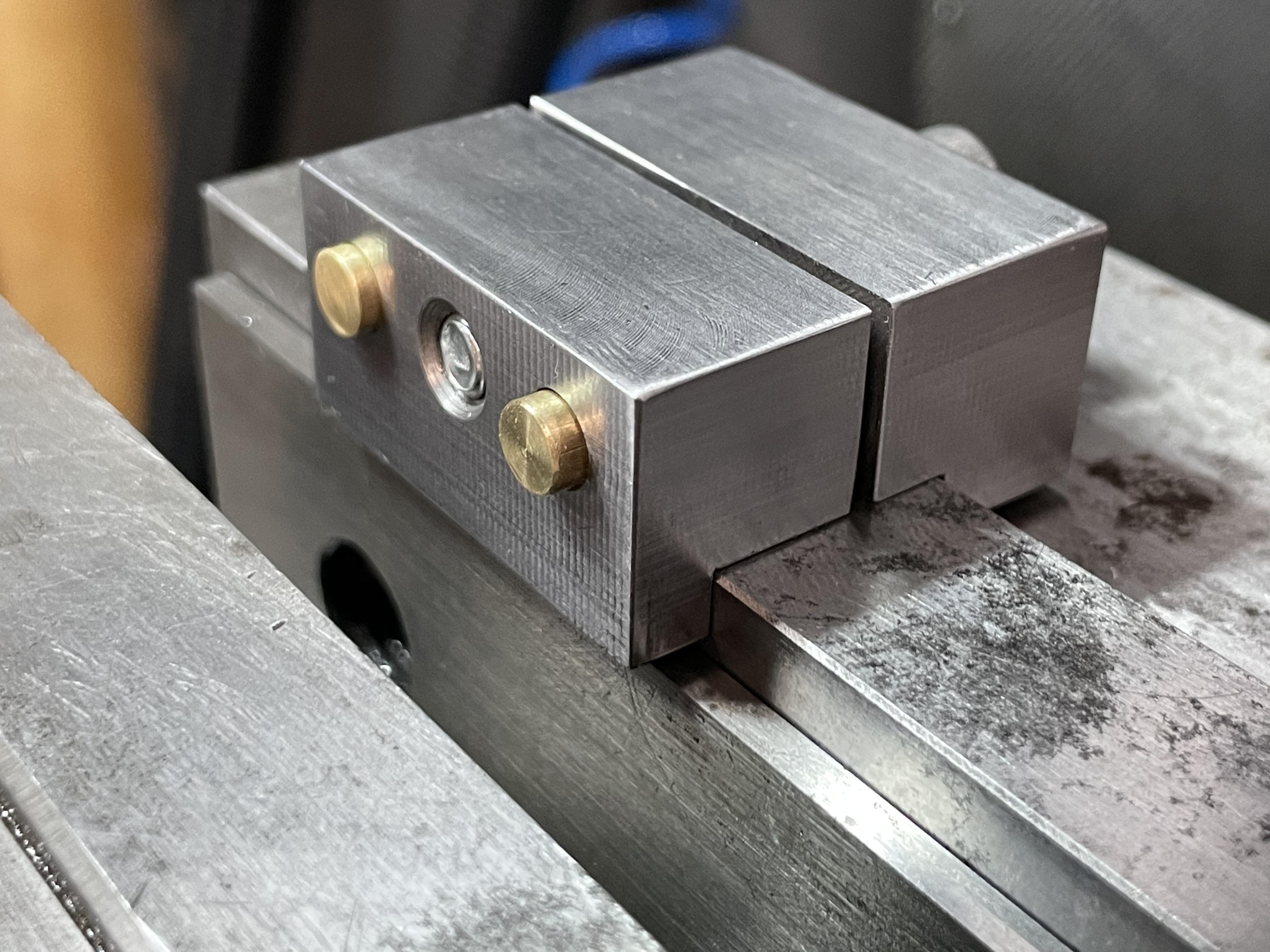

Went back and forth on how to make this part. Couldn't decide between lathe job, or Mill. CNC mill won out. Milled pocket for a 26mm OD bearing, and clearance for a bunch of other stuff. And, yeah, I didn't deburr on the mill. Feeling lazy.

Of course, it's far from done, but just glad the bearings fit snug. What really made me decide on the CNC mill was the need for two identical units. G code once, mill twice was faster.

Any guesses on what this is for?

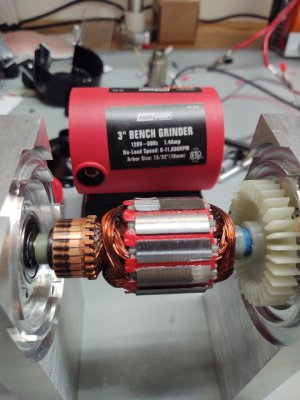

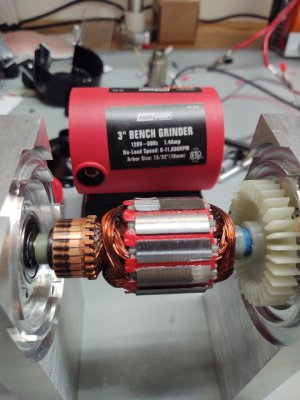

I you guessed diamond wheel dresser for the surface grinder, you'd be correct! Started thinking about cheaper options than the drag or powered wheel dressers that seem hard to find used. Bench grinder was what came to mind. After a quick youtube search, I found a guy who used a cheapie 3" grinder, so the concept seemed reasonable. However there was almost no rigidity in this $30 grinder. So, if you're going to over engineer something, go all the way!

Need a bunch of clearance for what's left of the base and around where the wheel guards go. Then a few holes for the steel plate that this aluminum will bolt to. But in general, Good enough for who it's for!