I bought a Harbor Freight hand plane (no 33) back when I built the table top for the family members last year. The hand plane was nearly impossible to use, because it felt like it was between revisions (threaded, knurled nuts adjusting blade depth were different sizes, though the threaded rod was the same 6x1.0mm). It was as-if someone at the factory crossed parts over. When I called customer service, they said I had to mail the whole unit back, and they'd send me a new one (I had to pay shipping both directions, and I think the shipping would have cost the same as just buying another one, but after that I couldn't mentally try another bad one).

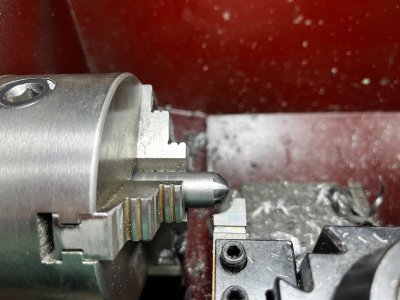

I had a 5/8" stainless bar drop from a previous project, and decided to use that. Faced, drilled to 5.2mm for tapping (sort of - I'm using metric, and ended up with an even bigger hole because this stainless was painful to tap even with the larger pilot hole). I got to use the scissor knurl for the first time.

If anyone has questioned whether to do the pressure knurling tools, or to go with the scissor knurling tools - by all means, spring the extra cash for the scissor knurling tool. It actually produced decent results for a first try, without breaking any tool post hardware!

I finished my other cuts and surfaces, and swore at this stainless - it was painful to tap. But, I got it done.

The plane is usable again. The stainless bar stock was probably worth more than I spent on the plane, but I did get my aroma therapy in for the first time in a few months (most of my time was spent making indoor grow racks for tomato plants, and sanding for a Gerstner-style machinist chest - I really need to get back to that project).

I have a 6 foot stainless grill that I have to put handles on for lifting later today . This was just lying around but I figure once the yard is up to snuff , we'll have a party .

I have a 6 foot stainless grill that I have to put handles on for lifting later today . This was just lying around but I figure once the yard is up to snuff , we'll have a party . I have a 6 foot stainless grill that I have to put handles on for lifting later today . This was just lying around but I figure once the yard is up to snuff , we'll have a party .

I have a 6 foot stainless grill that I have to put handles on for lifting later today . This was just lying around but I figure once the yard is up to snuff , we'll have a party .