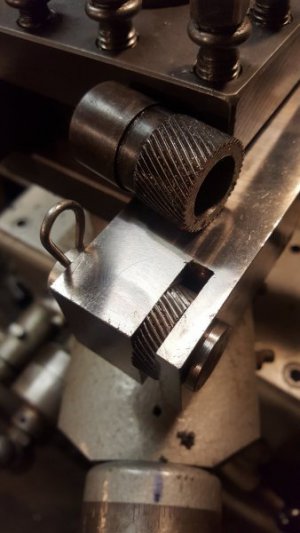

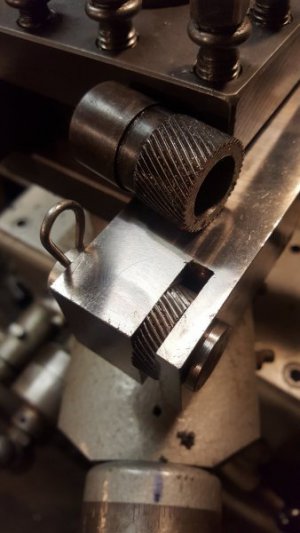

This kind of turned into 2 projects. My father in-law gave me several tools last year and one of them was this old 24" Starrett hight gage that was missing the scribe and scribe clamp. I made the clamp body and sharpened up a 1/4" hss turning tool for a scribe. I wanted the clamp screw to be similar to the original Starrett screws so I needed a knurling tool, and thats another project that I had on the back burner.

I got these 2 gizmos from a couple of automatic slack adjusters.

Other than making the tool body, pin and a 5/8" hole in the gear thingy, cutting a usable piece off of the gear was risky for everything but an abrasive saw. I didn't want to heat up the part too much so I used my niagra 4"slitting saw, which worked very well.

I made a test knurl on the opposite end of my drill rod. My first knurl ever. I wondered how deep it could go.

I lightly knurled my part, then I turned the knurling wheel over to make a nice diamond pattern. That's when I found out that it doesn't work like that. I was a little surprised. It turned out like this though.

It fit perfectly! Unless you want to measure all the way down to 1".

But the good news is my project told me exactly how much to remove off the bottom of the clamp.

Funny how things turn out sometimes.