- Joined

- Mar 20, 2014

- Messages

- 418

Nice idea to have the thrust bearing on the QCTP

EDIT: Noticed it about $7 on eBay for a needle thrust bearing like that with 2 washers!

yeah, they’re not expensive, and it makes tightening the post & getting more clamping pressure easier.

That's a fantastic looking restoration! I've never seen that nice a vise on a swivel (power) arm before. Panavise is nowhere near as good.

Thanks! Its only been sat on my workbench waiting to be mounted for 2 YEARS!

2018 POTD Thread Archive

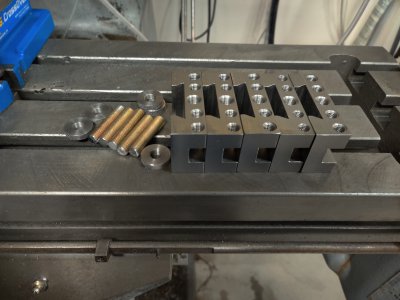

I used a cheap Mastercraft 3/4" socket, some 7/16" CRS and two 3/4" steel balls to make this speed handle for my Kurt vise. I drilled and tapped 3/8" holes in the balls and threaded both ends of the rod. I prefer just 2 arms on the handle instead of three like you see on most of them. It was...

www.hobby-machinist.com

www.hobby-machinist.com

Last edited: