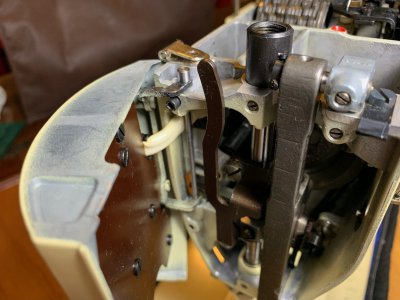

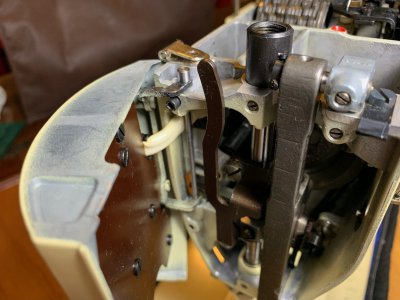

I decided to knock off early from work today so after a little shopping and a quick after-lunch nap I spent the afternoon in the shop. I needed a new hinge pin to replace the one I chewed up on the Bernina 730 I’m working on. Lovely pieces of engineering, Berninas, and equally masterful examples of quality manufacturing but I have to say the hinge pin was not their best moment! I mean really, the machine is only 51 years old after all! Well regardless, I wrecked the top of the original trying to get enough of a purchase to extract it so I had to come up with a new one.

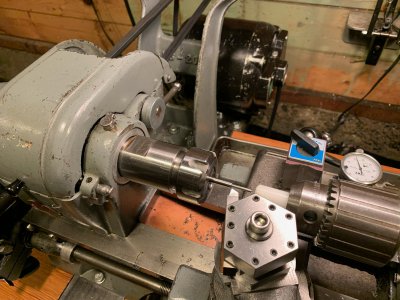

Berninas are Swiss so metric is the order of the day. This pin needed to be 2.5mm or just a hair under 0.1” by roughly three inches long. There is a screw that bears against the side of the pin to secure it in position so I wanted something that would stand up a bit better than just ordinary mild steel. I had a stick of W-1 that would be about right for head diameter, I just needed to turn the rest of the pin part down to 2.5mm and I’d be golden.

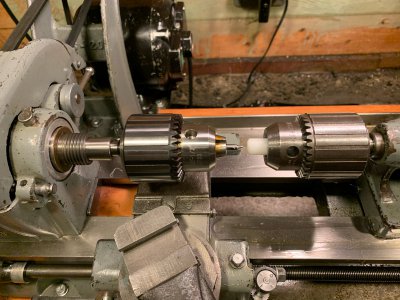

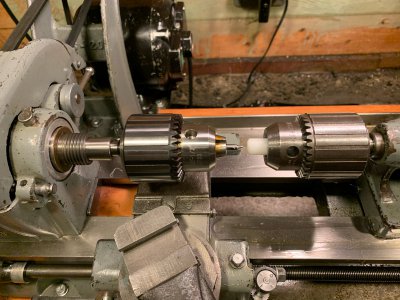

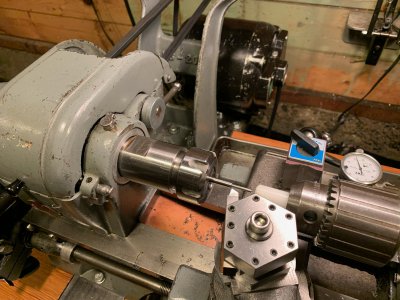

First things first, I chucked a scrap of HDPE in the tailstock and drilled through with a #39 bit. This would work kind of like a steady rest to help stabilize the turning as I thinned the diameter. Then I started whittling down the pin in stages: first 3/4”, then another 3/4”, then another, etc until I reached the necessary length. I worked each step to final diameter before moving to next one.

The original pin had a very small flat milled on the side where the locking screw would bear, but it was not large and someone had tightened the screw slightly off this flat causing a gall to raise on the pin. That’s why it was so durned hard to get out. I elected, instead of milling a flat, to turn a slightly reduced section all round so regardless of the pin orientation the screw would bear on the reduced portion.

With that done, a final cleanup and polish with some 320 paper and I parted off. I made the head 0.150” long and kept it cylindrical so it would afford a bit better purchase for whoever might have to pull it in future.

And there we are, slightly blurry but doing the job nicely.

Thanks for looking!

-frank