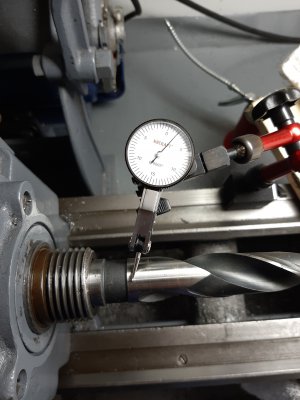

ive noticed in the past one time when I put a 3mt lil chuck attachment into the spindle I had big runout I blamed the lil chuck on being out of wack….recently I had to put a 3-2 adapter in there to machine a blank 2mt tool.. issues again..i bought a new 2-3 mt adapter as mine was old and looked welll beat up... now I think ive found my problem if you look down the spindle bore you can see a ridge... check the pics. its not even either it almost disappears in one area. im thnking the spindle would be pretty hard metal how did this happen? factory defect? did someone run a boring bar down there at some point? what are my options here? I have a dial indicator but not a test indicator.. need some wisdom on what to get there... I see some shars ones on amazon should I go .0005 or .0001

but n bubut

but n bubut