- Joined

- Feb 8, 2014

- Messages

- 11,144

Lately my project posts have been few and far between, not because I haven't been doing anything, but rather what I have been doing is protected by NDAs and I'm not allowed to show my work to the general public. I've actually been doing some pretty cool stuff, some of which has very interesting setups, work holding and machining challenges that tax my abilities.

I finally have a project that I can show.

Some of you may remember the servo driven punch press I built for a customer about 18 months ago. https://www.hobby-machinist.com/threads/servo-punch-press.72601/

It works OK, but there has been one nagging problem since day one. When the material spool is full, they can't run it at high feed rates because mass of the spool is more than the feed rolls can accurately accelerate. This means that someone has to stand there and spool off the material to keep some slack in the material so the feeder is free to accurately feed the material. I should note that we are trying to hold +/- 0.001 inch or better on feed position and thus the punched hole spacing. That sounds like a crazy tight tolerance, but concider that's 0.1 inch over 100 inches which is bordering on unacceptable. The good news is that the hole to hole actual position is + or - a bit so the average is pretty good.

Since this press is designed to allow variation of the feed length at a push of a button to make different product styles, the longer the distance between the punches means the more mass that needs to be accelerated between the punches, and the press is not able to position accurately at longer feed lengths without operator intervention. So to overcome this problem the customer has commissioned a pre-feeder, similar to a common punch press material spooler.

The goal is to try to keep a constant amount of loop in the material to minimize any feed error at any possible feed rate. And do it all automatically, while being able to feed material from spools staged on a seperate rack system.

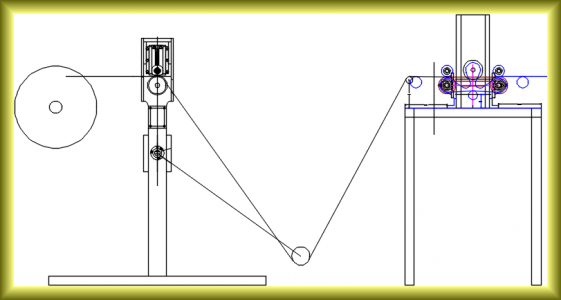

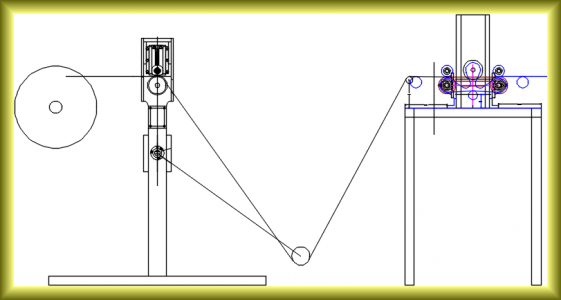

Here is the overall concept. This is shown in the rest position, material flow is left to right. The feed arm senses the loop height, and as the the loop height changes, the feed motor speeds up or slows down as needed to try to maintain a constant loop length. The sensor arm is connected to a pot that controls the VFD.

I'll post pictures of the pallet of raw materials and parts in the morning. All of the bits & pieces arrived yesterday, and I went shopping today to buy the steel, aluminum, and plastic needed to hang all of the parts on. Then you'll get to see it all take shape over the next couple of weeks.

Not a terribly complex project, but should be fun.

Stay tuned............

I finally have a project that I can show.

Some of you may remember the servo driven punch press I built for a customer about 18 months ago. https://www.hobby-machinist.com/threads/servo-punch-press.72601/

It works OK, but there has been one nagging problem since day one. When the material spool is full, they can't run it at high feed rates because mass of the spool is more than the feed rolls can accurately accelerate. This means that someone has to stand there and spool off the material to keep some slack in the material so the feeder is free to accurately feed the material. I should note that we are trying to hold +/- 0.001 inch or better on feed position and thus the punched hole spacing. That sounds like a crazy tight tolerance, but concider that's 0.1 inch over 100 inches which is bordering on unacceptable. The good news is that the hole to hole actual position is + or - a bit so the average is pretty good.

Since this press is designed to allow variation of the feed length at a push of a button to make different product styles, the longer the distance between the punches means the more mass that needs to be accelerated between the punches, and the press is not able to position accurately at longer feed lengths without operator intervention. So to overcome this problem the customer has commissioned a pre-feeder, similar to a common punch press material spooler.

The goal is to try to keep a constant amount of loop in the material to minimize any feed error at any possible feed rate. And do it all automatically, while being able to feed material from spools staged on a seperate rack system.

Here is the overall concept. This is shown in the rest position, material flow is left to right. The feed arm senses the loop height, and as the the loop height changes, the feed motor speeds up or slows down as needed to try to maintain a constant loop length. The sensor arm is connected to a pot that controls the VFD.

I'll post pictures of the pallet of raw materials and parts in the morning. All of the bits & pieces arrived yesterday, and I went shopping today to buy the steel, aluminum, and plastic needed to hang all of the parts on. Then you'll get to see it all take shape over the next couple of weeks.

Not a terribly complex project, but should be fun.

Stay tuned............

Last edited: