-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pretty sure I need a mill part 2 cleanup

- Thread starter DeadGuyAle

- Start date

- Joined

- Mar 22, 2022

- Messages

- 340

I need to look at the other side of the table, one would expect a oiler there alsoWonder if it's worth putting a one-shot system on these little mills. Yours is almost identical to the one I just got, I'm sure you will enjoy working with it....

The other oiling points oil the ends of the lead screw

- Joined

- Mar 22, 2022

- Messages

- 340

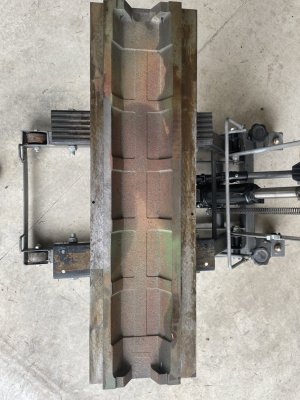

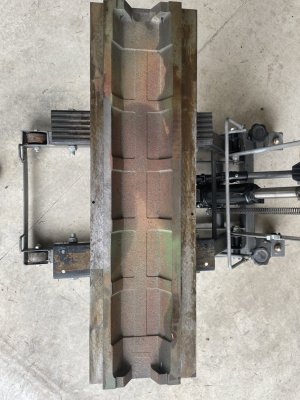

Started out with this

Came out like this

Still figuring out how to remove the table.

Ordered gates belts and the head bolt kit recommended by

Came out like this

Still figuring out how to remove the table.

Ordered gates belts and the head bolt kit recommended by

Me and a few others on this site have done a few mods to make the Rong Fu more reliable. There are a few big threads and lots of scattered posts on these improvements, but you have to dig around.

Here's a tip that I wanted to share since your first picture posts. I don't think head alignment jigs are necessary, but the head bolt upgrade made a world of difference:

RF-30 Clone Head Alignment Guide

Rob,- Now you have me going again, mine has two belts. Does three mean you have a power quill down drive?www.hobby-machinist.com

- Joined

- Jan 2, 2019

- Messages

- 6,488

I‘ve got mine pretty well cleaned up, not quite like yours but much better than when I bought it. Why do you want to remove the table, does it need service or do you just want to have gone through everything before you start using it?Started out with thisView attachment 414414

Came out like this

View attachment 414415

Still figuring out how to remove the table.

Ordered gates belts and the head bolt kit recommended by

John

- Joined

- Dec 2, 2012

- Messages

- 1,721

I found a ball oiler on the table, you can see it in the second to last picture above!

Just the one oiler thats interesting, have you found one on the back of the table also ?

Stu

- Joined

- Mar 3, 2020

- Messages

- 506

DeadGuy, the rear table oiler on mine is opposite the front oiler. Kinda hard to see.

your machine looks exactly like my Griz G1007 except for the color.

mine was made in 2004.

should be a date on the motor that will give close date of build.

your machine looks exactly like my Griz G1007 except for the color.

mine was made in 2004.

should be a date on the motor that will give close date of build.

- Joined

- Mar 22, 2022

- Messages

- 340

don’t think it will be that time intensive to do the table and let’s me keep my AR tendinitis intactI‘ve got mine pretty well cleaned up, not quite like yours but much better than when I bought it. Why do you want to remove the table, does it need service or do you just want to have gone through everything before you start using it?

John

24 years of never been used and collecting dust is the primary driver

Indeed there isJust the one oiler thats interesting, have you found one on the back of the table also ?

Stu

Correct on the oilerDeadGuy, the rear table oiler on mine is opposite the front oiler. Kinda hard to see.

your machine looks exactly like my Griz G1007 except for the color.

mine was made in 2004.

should be a date on the motor that will give close date of build.

motor shows a1998 build date

- Joined

- Mar 22, 2022

- Messages

- 340

Removing the table was somewhat intimating and a bit of a mental block for me.

Not much documentation but looks fairly simple mechanically, some concern about the weight (I’m less than young). Got over it and was very straight forward all said and done.

Crank it full right

Remove the end caps, right side has inner and outer bearings sets (both pretty much without grease)

Next you unscrew the lead screw and everything is free

Not much documentation but looks fairly simple mechanically, some concern about the weight (I’m less than young). Got over it and was very straight forward all said and done.

Crank it full right

Remove the end caps, right side has inner and outer bearings sets (both pretty much without grease)

Next you unscrew the lead screw and everything is free

- Joined

- Mar 22, 2022

- Messages

- 340

Pulled the gib at this point and put my extensive array of material handling equipment into use.

Done and Done

it is heavy as one might expect

Flipped it over

Flipped it over

Little scrubbing and looking good

knocked the burrs off the edges with a file. Lot’s of embedded milling grit on most surfaces so feel like it was time well spent so far,

Done and Done

it is heavy as one might expect

Flipped it over

Flipped it over

Little scrubbing and looking good

knocked the burrs off the edges with a file. Lot’s of embedded milling grit on most surfaces so feel like it was time well spent so far,

Last edited:

- Joined

- Mar 22, 2022

- Messages

- 340